- all

- product

- blog

- all

- product

- blog

Details

HC SERIES SUPER LARGE GRINDING MILL

Technological revolution in pendulum mill industry, traditional Raymond mill replacement products.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

HC large-scale pendulum mill is a large-scale product based on the company's HC1700 vertical pendulum mill. This series of mills is a large-scale environmentally friendly milling equipment independently developed by Guilin Hongcheng Mining Equipment Manufacturing Co., Ltd., covering 5 invention patents. The fineness range of its products is between 38-180μm (80-400 mesh), which can meet the domestic industrial policy and the expanding demand of industrialized scale production, make up for the blank of my country's large-scale pendulum mill, and expand the pendulum mill The application field of the powder machine, whether in terms of production capacity or unit energy consumption, has greatly improved the user's equipment efficiency, and its technical level will be at the domestic advanced level. The successful development of the HC large-scale pendulum mill can replace almost all types of mills with an output of up to 90 tons per hour, and is particularly suitable for large-scale powder processing in industries such as power plant desulfurization and manganese mining.

Finished product size: 38-180μm

Production capacity: 3-90t/h

This product is suitable for grinding limestone, calcite, talc, dolomite, titanium dioxide, quartzite, bauxite, marble, feldspar, barite, fluorite, gypsum, ilmenite, phosphate rock, clay, graphite, Clay, kaolin, diabase, coal gangue, wollastonite, lime, zircon sand, bentonite, manganese ore and other non-flammable and explosive materials with Mohs hardness below 7 and humidity within 6%.

ADVANTAGES AND FEATURES

|

equipment operation. |

The shock-absorbing shaft sleeve made of rubber and wear-resistant materials not only effectively isolates the vibration generated by the operation of the equipment, but also changes the short service life and frequent maintenance defects of the rubber sleeve structure used in the old Raymond mill, ensuring production continuity. |

|

The special feeding method allows the raw materials to be evenly distributed in the mill, which improves the rolling rate, which is more conducive to the crushing of the powder, the grinding area wears evenly, and the service life of the wear-resistant parts is prolonged. |

The new structure of spider-arm is compact, reasonable and reliable. The grinding ring can be updated without disassembling it, reducing maintenance time and avoiding additional failures caused by the previous Raymond mill’s quincunx structure. |

|

Using unique wear-resistant high-chromium alloy material technology, it is more suitable for high-frequency, heavy-load collision and rolling conditions, and the service life is nearly three times longer than the industry standard. |

The combined hood structure makes it simpler and more convenient to maintain and repair without disassembling other parts when the grinding roller is worn out. |

|

The classifier adopts large-scale forced turbine classification technology, which has large processing capacity and high classification efficiency. The particle size of the finished product can be adjusted between 80-400 mesh. At the same time, it can adopt air-sealed barrier technology with high classification accuracy to ensure the qualified rate of fineness. |

The off-line dust cleaning pulse dust collection system or residual air pulse dust collection system is adopted, which has a strong dust removal effect, a long service life of the filter bag, and a dust collection efficiency of up to 99.9%. It is more suitable for dust collection conditions with high dust concentration and large moisture. |

|

Multi-layer barrier structure is used to ensure the sealing of the grinding roller device (patent number CN200820113450.1): The working environment of the grinding roller device is high dust concentration, and the grinding roller device of the traditional R-type pendulum mill cannot be reliably sealed by stacking. For bearing sealing, the grinding roller assembly needs to be oiled and maintained every day. The HC large-scale pendulum mill adopts maintenance-free oil seal technology, spiral seal and multi-layer barrier structure of skeleton oil seal, which can effectively prevent the entry of dust and maintain the normal working condition of the grinding roller assembly. It can be refilled every 500-800 hours. Grease greatly reduces equipment maintenance time and maintenance costs. | ||

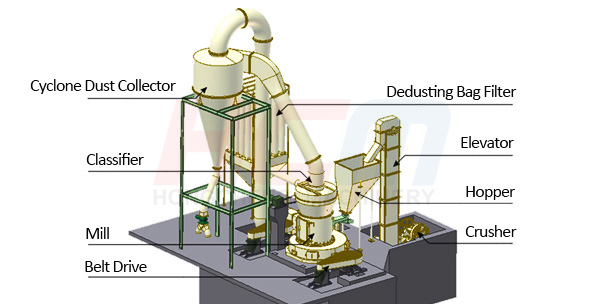

MILL STRUCTURE & WORKING PRINCIPLE

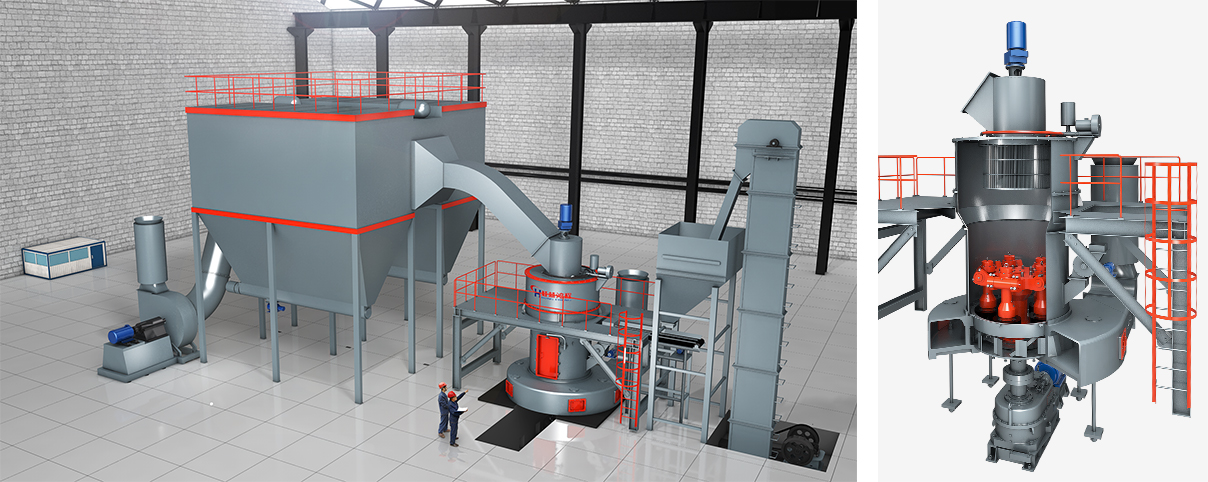

The HC pendulum mill system is composed of a grinding host, grading and screening, product collection, and other components.

The host adopts an integral casting base structure and can adopt a shock-absorbing foundation. The classification system adopts a mandatory turbine classifier structure, and the collection system adopts pulse collection. The process flow of the pulverizing system: the raw materials are transported by a special vehicle to the semi-open raw material shed, and then shoveled by a forklift to the lower hopper, crushed by a crusher to less than 40mm, and the material is lifted by a hoist to a storage hopper in front of the mill; When the material is discharged from the hopper, the material will be evenly sent to the host by the feeder for grinding. The qualified products in the grinding process are classified and screened by the classifier, and then enter the pulse dust collector through the pipeline. After being collected by the pulse dust collector, the products are discharged through the discharge port at the lower end of the pulse dust collector. Unified delivery to the powder storage bin. This system is designed as an open-circuit system, the dust collection is full pulse collection, the pulse collection efficiency is 99.9%, the output of the mill will inevitably increase, and it is more environmentally friendly. For the finished product, the user can perform the next set of procedures for deep processing according to the actual process. The single unit of HC large-scale mill has a large output, which cannot be packed manually, and must be transported to the powder storage tank before packaging.

TECHNICAL DATA

| Model | Roller Number | Ring Diameter (mm) |

Max. Feeding Size (mm) |

Fineness (mm) |

Capacity (t/h) |

Total Power (kw) |

| HC1900 | 5 | 1900 | 40 | 0.038-0.18 | 10-35 | 555 |

| HC2000 | 5 | 2000 | 40 | 0.038-0.18 | 15-45 | 635-705 |

| HC2500 | 6 | 2500 | 40 | 0.038-0.18 | 30-60 | 1210 |

| HC3000 | 6 | 3000 | 40 | 0.038-0.18 | 45-90 | 1732 |

Note:

1.The above models are euiped with newly designed spider-arm structure.

2.The capacity is for calcite (Feeding size≤10)powder, and specification is just a reference. The actual production depends on these materials being processed.

MATERIAL PROCESSING

Guilin Hongcheng pulverizing equipment is used in large-scale non-metallic mineral pulverizing, environmentally friendly desulfurized limestone pulverizing, calcium carbonate pulverizing, large-scale pulverized coal equipment, petroleum coke fuel industry, manganese ore processing, slag, water slag, and comprehensive utilization of fly ash , Gypsum powder and many other fields.

Coal Petroleum coke Slag Cement clinker

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE