- all

- product

- blog

- all

- product

- blog

Details

ULTRAFINE GRINDER RAW VERTICAL TURBINE TYPE GRINDING MILL FACTORY

The main component of marble is calcium carbonate, which accounts for more than 50%. Others include magnesium carbonate, calcium oxide, manganese oxide and silicon dioxide. Crushed stones and leftover materials produced during mining and processing are also commonly used in the production of artificial stone, terrazzo, stone rice, and stone powder, and can be used as fillers in coatings, plastics, rubber and other industries.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

HCH series ULTRAFINE GRINDER has comprehensive mechanical crushing properties such as roller compaction, milling, impact, etc. It is widely used in ultrafine crushing of various non-metallic minerals with Mohs hardness below 7 and humidity within 6%, such as calcium carbonate. Hongcheng HCH1395 is the super-large ultra-fine ring roller mill in China.

Fineness: 5-45μm (325-2500 mesh)

Production capacity: 1-22t/h

The main component of marble is calcium carbonate, which accounts for more than 50%. Others include magnesium carbonate, calcium oxide, manganese oxide and silicon dioxide. Crushed stones and leftover materials produced during mining and processing are also commonly used in the production of artificial stone, terrazzo, stone rice, and stone powder, and can be used as fillers in coatings, plastics, rubber and other industries. Marble powder is widely used. Different types of calcite mills can be selected according to the requirements of the fineness of the finished product.

1. 80 mesh-200 mesh:

It can be used in construction, interior and exterior wall coatings, chemical material filling, weighting, papermaking, various sealants and other chemical products.

2. 250 mesh-300 mesh:

It can be used as a raw material for plastics, rubber, coatings and waterproof materials.

3. 400 mesh to 600 mesh:

It can be used for toothpaste and soap.

4. Above 800 mesh:

Used in rubber, plastics, cables, PVC fillers and other fields.

5. Above 1250 mesh

It can be used to make PVC, PE, paint, coating products, papermaking primer, papermaking topcoat, ink, etc.

ADVANTAGES AND FEATURES

|

The broken ratio is big. Feeding non-metallic mineral particles with a particle size of<10mm can be processed into fine powder of <10μm (under the pass rate of 97%) at one time, and the fine powder of -3μm accounts for about 40%, with a large specific surface area. It has the advantages of high-speed impact mill to produce powder and low consumption,and it has the product fineness close to jet mill. |

Environmental protection. The pulse dust collection system (patent:CN200920140944.3) has a dust collection rate of over 99.9%,ensuring dust-free operation in the workshop. Thorough dust removal: The pulse dust collection system adopts a pulse-jet dust removal method, which uses compressed air to clean each filter bag separately. The cleaning kinetic energy is higher and more thorough, thereby preventing the long-term backlog of powder. The powder is on the filter bag for a long time. Retention and clogging of the filter bag. |

|

|

Forced turbine classification technology (patent: ZL201030143470.6), the finished particle size can be adjusted between 45μm and 5μm. |

The roller and ring are made of special wear-resistant steel, which has a long service life. The base is firm and has good shock absorption performance. |

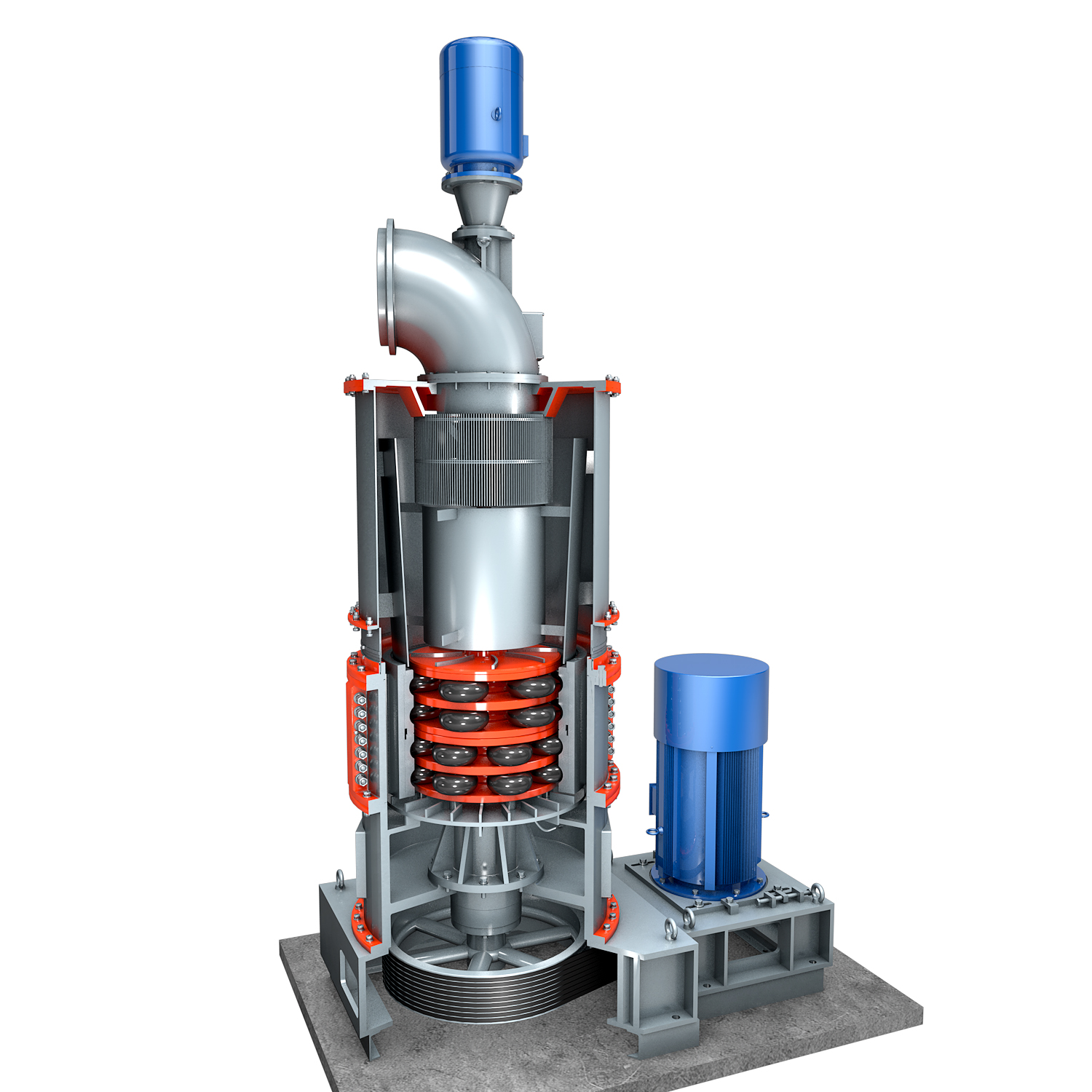

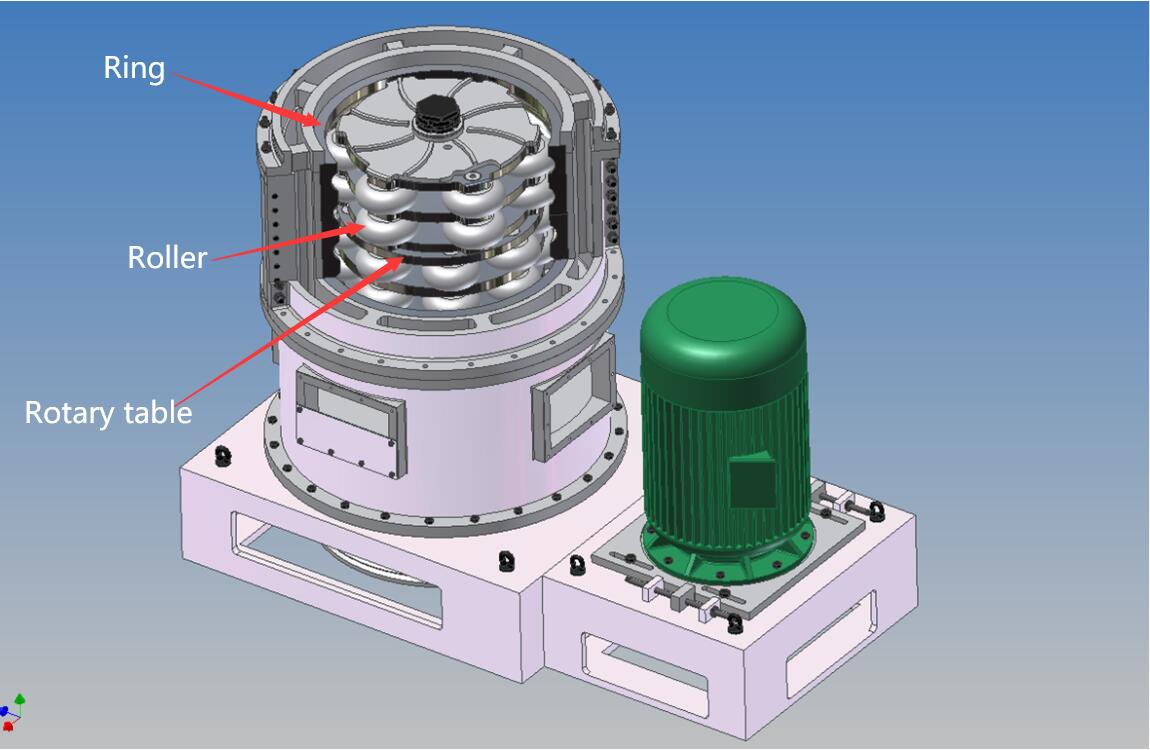

MILL STRUCTURE

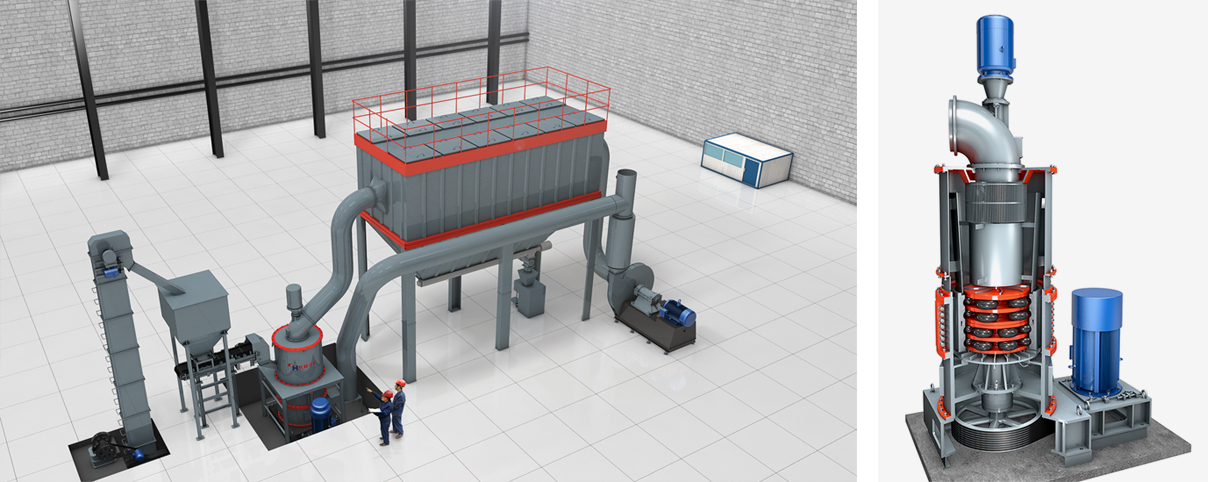

The complete system of HCH RAW VERTICAL TURBINE TYPE GRINDING MILL is mainly composed of main machine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc.

WORKING PRINCIPLE

The grinding roller mounted on the rotary table in the main machine chamber rotates around the central axis, and there is a large gap between the grinding roller and the grinding roller pin. Under the action of centrifugal force, the grinding roller swings horizontally outward, so that the grinding roller compacts the grinding ring, and the grinding roller rotates around the grinding roller pin at the same time. Through the gap between the grinding roller and the grinding ring, the material can be crushed and ground by the grinding roller. The grated powder falls to the chassis under the action of gravity and is blown to the classifier above the main engine for screening under the action of a blower. The air path is circulating, except for the positive pressure from the blower to the grinding chamber, the gas in other pipelines flows under negative pressure. The material contains water, which evaporates into gas when it is heated during grinding. The air entering into the gas at various joints in the pipeline leads to the increase of the air volume in the circulating air path. The increased air volume is discharged into the atmosphere through the bellows interface between the blower and the main engine.

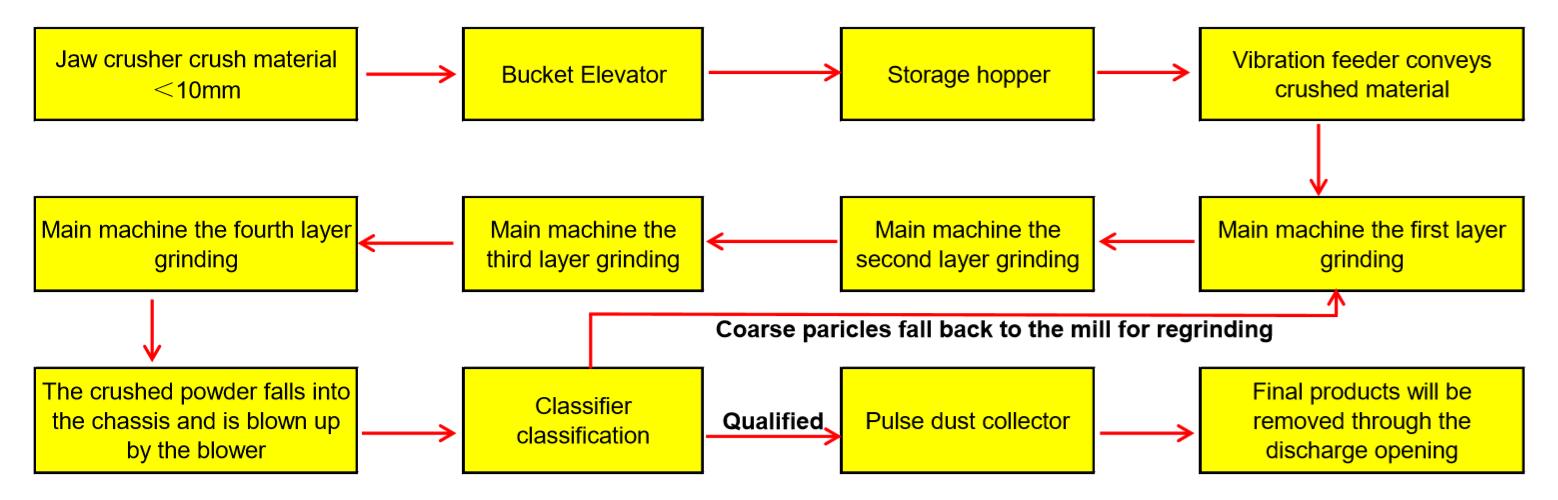

MARBLE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of MARBLE are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of MARBLE are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Number | Ring Number |

Ring Inner Diameter (mm) |

Max. Feeding Size (mm) |

Fineness (mm) |

Capacity (t/h) |

Main Motor Power (kw) |

Blower Power (kw) |

Classifier Motor Power (kw) |

| HCH780 | 5 |

2 |

730 |

≤10 |

0.04

0.005 |

0.78-3.8 | 75 | 37 | 22 |

| 12 | |||||||||

| HCH980 | 12 | 2 | 880 | ≤10 | 1.3-6.8 | 132 | 75 | 30 | |

| 16 | |||||||||

| HCH1395 | 16 | 2 |

1100 | ≤10 |

2.6-11 |

200 | 160 | 75 | |

| 20 |

Note:

The capacity is for calcite powder(feeding size ≤10), and specification is just a reference. The actual production depends on these materials being processed.

SUCCESSFUL CASES

ULTRA FINE MARBLE POWDER MILL PROJECT

Processing material: Marble

Fineness: 800 mesh D97

Output: 6-8t/h

Equipment configuration: 2 HCH1395

OTHER RELATED RECOMMENDATIONS

CALCITE POWDER MAKING–HLMX SUPERFINE VERTICAL MILL MARBLE MICRO POWDER TECH SOLUTIONS GRINGDER CALCITE GRINDING MILL-CALCITE POWDER APPLICATION MILL SUPPLIER EQUIPMENT SUPPLIER

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE