- all

- product

- blog

- all

- product

- blog

Details

SUPER FINE TALC ENERGY EFFICIENT NONMETALLIC GRINDING MILL MANUFACTURING PRICE

Talc has excellent physical and chemical properties such as lubricity, anti-sticking, flow aid, fire resistance, acid resistance, insulation, high melting point, chemical inactivity, good hiding power, softness, good gloss, and strong adsorption. Therefore, talc has a wide range of uses in cosmetics, medicine, papermaking, plastics and other fields.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

Talc is a common silicate mineral, soft in nature, its Mohs hardness coefficient is 1 to 1.5, and it has a slippery feel. Talc has excellent physical and chemical properties such as lubricity, anti-sticking, flow aid, fire resistance, acid resistance, insulation, high melting point, chemical inactivity, good hiding power, softness, good gloss, and strong adsorption. Therefore, talc has a wide range of uses in cosmetics, medicine, papermaking, plastics and other fields.

Cosmetics field

Used in various emollient powder, beauty powder, talcum powder, etc. It has the effect of blocking infrared rays, so it enhances the sunscreen and infrared ray resistance of cosmetics.

Medicine-food field

Used as additives for pharmaceutical tablets, pharmaceutical powders (such as argafen powder), sugar coatings, prickly heat powder, Chinese medicine prescriptions, food additives, release agents, etc. It has the characteristics of non-toxic, odorless, high whiteness, good compatibility, strong gloss, soft taste and strong smoothness.

Coating field

Used in white body pigments and various water-based, oil-based, resin industrial coatings, primers, protective paints, etc. Increase the stability of the product shape.

Papermaking field

It is used as filler for all kinds of paper and cardboard, wood asphalt control agent. It can achieve smooth and delicate paper, save raw materials, and improve the service life of the grease net.

Plastic field

It is used as a filler for polypropylene, nylon, polyvinyl chloride, polyethylene, polystyrene, polyester and other plastics. Increase tensile strength, shear strength, bending strength, compression strength, and reduce deformation.

Rubber field

Used as anti-sticking agent for rubber packing and rubber products. Increase the stability of the product shape, increase the tensile strength, shear strength, bending strength, and pressure strength.

Cable field

Used as cable rubber extender and cable isolating agent.

Ceramic field

Used in the manufacture of electric porcelain, radio porcelain, various industrial ceramics, architectural ceramics, daily-use ceramics and enamels. It has the characteristics of no discoloration at high temperature, enhanced whiteness after calcination, uniform density, good gloss and smooth surface.

Waterproof material field

Used for waterproofing membrane, waterproof coating, waterproof ointment, etc.

HCH SUPER FINE TALC ENERGY EFFICIENT NONMETALLIC GRINDING MILL is a new type of high-fine grinding equipment newly developed by Guilin Hongcheng accumulated years of production and R&D experience. The product fineness can be adjusted between 325 mesh and 2500 mesh according to needs, and the product fineness is once The performance can reach D97≤5um. HCH is a real energy-saving, high-fine grinding equipment especially suitable for deep processing of non-metallic minerals. HCH has comprehensive mechanical crushing properties such as roller compaction, milling, impact, etc. It is widely used in ultrafine crushing of various non-metallic minerals with Mohs hardness below 7 and humidity within 6%, such as calcium carbonate. Hongcheng HCH1395 is the super-large ultra-fine ring roller mill in China.

The mill is a high-fine powder processing equipment with small footprint, strong complete set, wide use, simple operation, convenient maintenance, stable performance, high cost performance, and energy saving.

Particle size of finished product: 5-45μm (325-2500 mesh)

Production capacity: 1-22t/h

ADVANTAGES AND FEATURES

|

The broken ratio is big. Feeding non-metallic mineral particles with a particle size of<10mm can be processed into fine powder of <10μm (under the pass rate of 97%) at one time, and the fine powder of -3μm accounts for about 40%, with a large specific surface area. It has the advantages of high-speed impact mill to produce powder and low consumption,and it has the product fineness close to jet mill. |

Environmental protection. The pulse dust collection system (patent:CN200920140944.3) has a dust collection rate of over 99.9%,ensuring dust-free operation in the workshop. Thorough dust removal: The pulse dust collection system adopts a pulse-jet dust removal method, which uses compressed air to clean each filter bag separately. The cleaning kinetic energy is higher and more thorough, thereby preventing the long-term backlog of powder. The powder is on the filter bag for a long time. Retention and clogging of the filter bag. |

|

|

Forced turbine classification technology (patent: ZL201030143470.6), the finished particle size can be adjusted between 45μm and 5μm. |

The roller and ring are made of special wear-resistant steel, which has a long service life. The base is firm and has good shock absorption performance. |

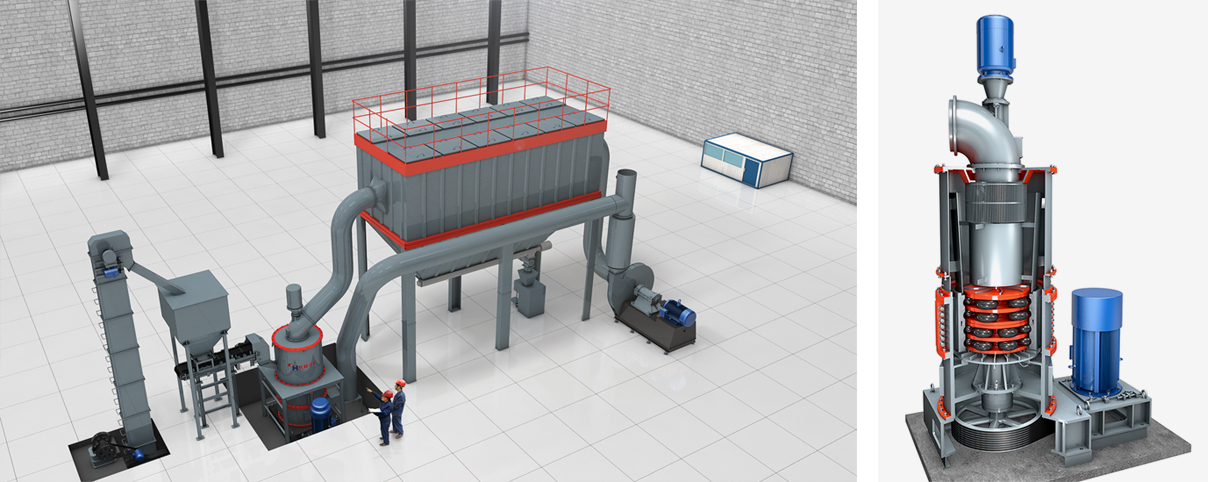

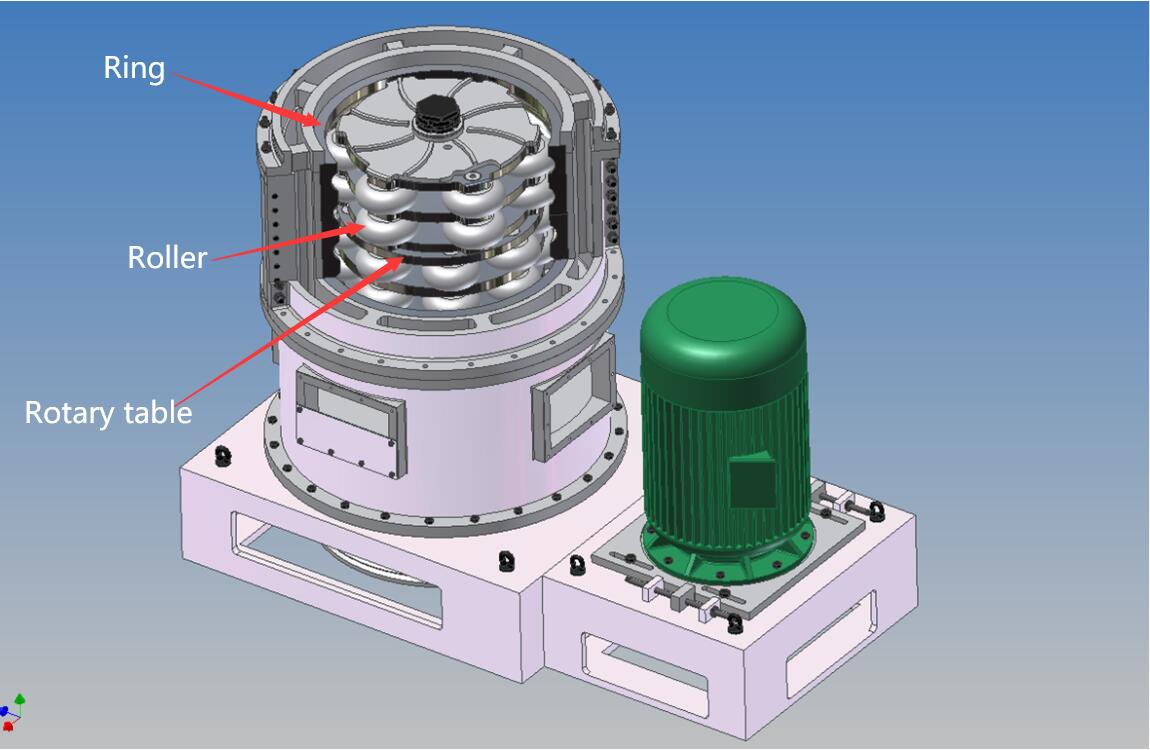

MILL STRUCTURE

The complete system of HCH talc grinding mill is mainly composed of main machine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc.

WORKING PRINCIPLE

The grinding roller mounted on the rotary table in the main machine chamber rotates around the central axis, and there is a large gap between the grinding roller and the grinding roller pin. Under the action of centrifugal force, the grinding roller swings horizontally outward, so that the grinding roller compacts the grinding ring, and the grinding roller rotates around the grinding roller pin at the same time. Through the gap between the grinding roller and the grinding ring, the material can be crushed and ground by the grinding roller. The grated powder falls to the chassis under the action of gravity and is blown to the classifier above the main engine for screening under the action of a blower. The air path is circulating, except for the positive pressure from the blower to the grinding chamber, the gas in other pipelines flows under negative pressure. The material contains water, which evaporates into gas when it is heated during grinding. The air entering into the gas at various joints in the pipeline leads to the increase of the air volume in the circulating air path. The increased air volume is discharged into the atmosphere through the bellows interface between the blower and the main engine.

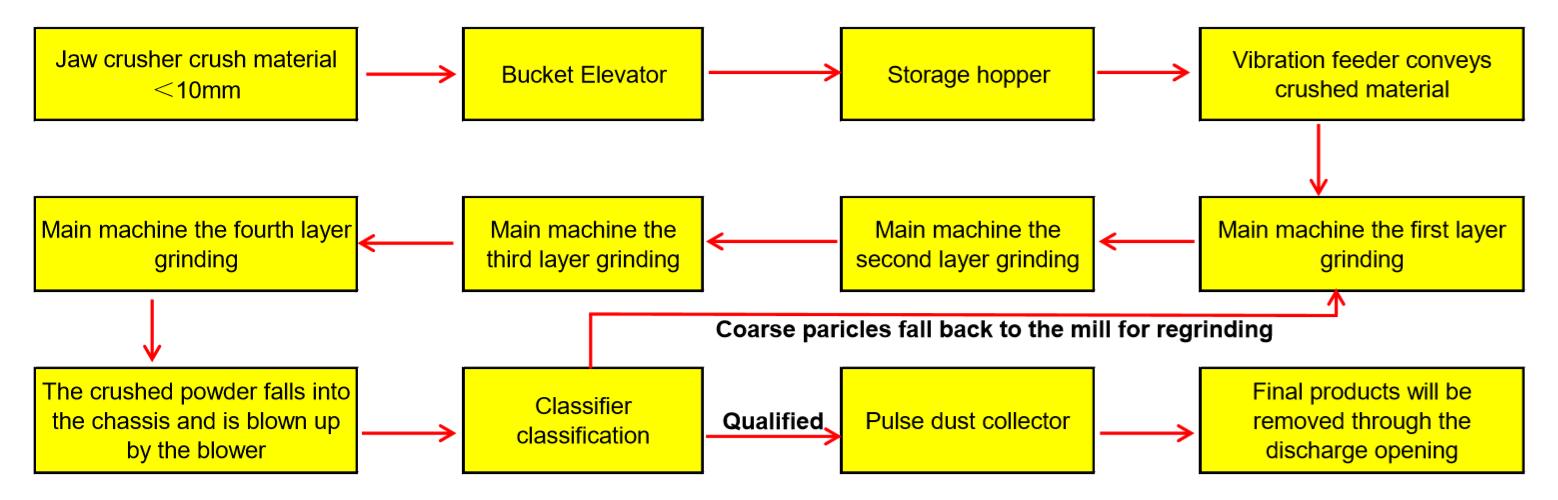

TALC POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of TALC are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of TALC are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Number | Ring Number |

Ring Inner Diameter (mm) |

Max. Feeding Size (mm) |

Fineness (mm) |

Capacity (t/h) |

Main Motor Power (kw) |

Blower Power (kw) |

Classifier Motor Power (kw) |

| HCH780 | 5 |

2 |

730 |

≤10 |

0.04

0.005 |

0.78-3.8 | 75 | 37 | 22 |

| 12 | |||||||||

| HCH980 | 12 | 2 | 880 | ≤10 | 1.3-6.8 | 132 | 75 | 30 | |

| 16 | |||||||||

| HCH1395 | 16 | 2 |

1100 | ≤10 |

2.6-11 |

200 | 160 | 75 | |

| 20 |

Note:

The capacity is for calcite powder(feeding size ≤10), and specification is just a reference. The actual production depends on these materials being processed.

OTHER RELATED RECOMMENDATIONS

CALCITE POWDER MAKING–HLMX SUPERFINE VERTICAL MILL MARBLE MICRO POWDER TECH SOLUTIONS GRINGDER CALCITE GRINDING MILL-CALCITE POWDER APPLICATION MILL SUPPLIER EQUIPMENT SUPPLIER

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE