- all

- product

- blog

- all

- product

- blog

Details

Raymond Mill for Calcite Powder Making

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

Raymond Mill for Calcite Powder Making

When it comes to the preparation of calcite powders, HC Milling (Guilin Hongcheng) is a popular and professional manufacturer and supplier of Raymond grinding mills. The new Raymond grinding mill provided by HC Milling (Guilin Hongcheng) is an ideal choice for the preparation of calcite powders at top quality due to higher capacity, lower energy consumption, energy saving, intelligence and efficiency. HC Milling (Guilin Hongcheng) tailors the selection plan according to the customer’s information such as fineness, capacity, production area, etc.

The main mineral of limestone and marble are calcite. And it is widely applied in production and life. Fine powders of GCC(Grinding Calcite Carbonate ) are used as fillers of products such as artificial stones, bricks, natural rubbers, synthetic rubbers, coatings, plastics, newly composite plastics, cables, paper making, toothpastes, cosmetics, glasses, medicines, paints, inks, cables, electrical insulation, foods, textiles, feeds, adhesives, sealants, asphalts, building materials, linoleum, fireproof ceilings and household chemicals.

Raymond grinding mill provided by HC Milling (Guilin Hongcheng) is very popular for the preparation of calcite powders because it is with more stable performance, more efficient operation and higher efficiency of grinding. HC Milling (Guilin Hongcheng) seriously serves each customer, deeply studies the grinding site as well as customer’s needs and tailors the selection plan so as to reduce customers’ comprehensive investment cost with better combination of resource, improve the efficiency, price scientifically and help the powder enterprises increase productivity and incomes.

#RaymondGrindingMill #HCMilling #GuilinHongcheng

Raymond Grinding Mill for Calcite Powder Making

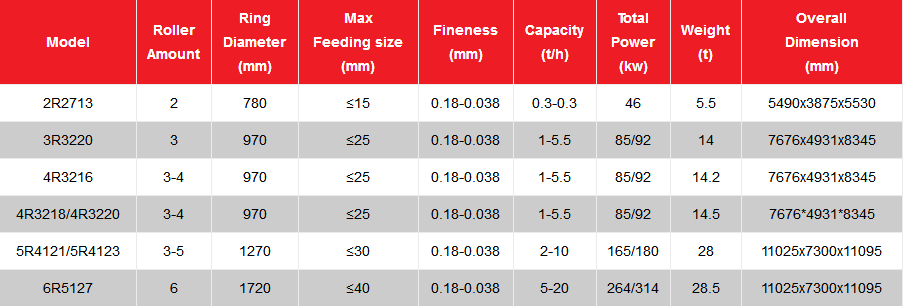

Diameter of grinding roller : 1000-1700mm

Total power: 85-362KW

Number of grinding rollers: 3-5

Capacity: 1-25t/h

Fineness of finished product: 0.022-0.18mm

Application areas:

It is widely used in fields such as electric power, metallurgy, cement, chemical, non-metallic mineral, food, medicine, etc.

Applicable materials:

It is widely used to grind and process various non-metallic materials with Mohs hardness below 7 and humidity below 6% such as diabase, coal gangue, wollastonite, graphite, clay, kaolin, lime, zircon sand, bentonite and manganese ore.

Characteristics:

This kind of grinding mill covering many patents focuses on the grinding and processing non-metallic minerals. The fineness of finished product can be freely adjusted between 80 mesh and 600 mesh. It is characteristic of small footprint, wide application, strong seismic resistance, solid structure, simple operation, easy maintenance, stable performance, high performance and so on.

The daily inspection items of the milling machine:

1. Regularly listening to the normal operation sound of the mill and the classifier, and whether there is any abnormal sound.

2. Checking if the reducer and other equipment has any oil leakage, water leakage or material leakage.

3. Checking the wear of the tie rod seal every month.

4. Regularly check the function of the scraper and returning system.

5. Checking the pumping station every day, including: oil level of the fuel tank and refueling if necessary. The oil should be in accordance with the specified oil; check the pressure of each pressure gauge; check whether the filters are blocked.

6. Checking the oil return condition of the grinding roller lubrication station and whether the oil filling pressure is normal.

7. Always check the oil pipes and valves for oil leakage.

8. Measuring the wear of the grinding disc and the grinding roller liner each 1000H, and make a record.

9. Checking the pressure of the accumulator once a week.

10. Regularly check the center frame, nozzle ring, air guiding vane, water spray pipe and other grinding accessories.

Grinding Mill maintenance:

1. There should be a fixed person responsible for operation in using process, the operator must equipped with professional technical knowledge. Before the installation, the operator must carry out the necessary technical training to understand the principle performance of the mill and familiar with the operating procedures.

2. In order to keep the mill in good condition, the "safe operation system for equipment maintenance" should be established, and necessary maintenance tools as well as grease and corresponding accessories should be provided.

3. After using the grinding machine for a period of time, it should be repaired and maintained. Meanwhile, the wearing parts such as grinding rolls, grinding rings and blades should be repaired and replaced. The grinding roller device should be carefully check the connection bolt nut before use and after, see if there is looseness, whether the grease is sufficient. The refueling tools are available with manual refueling pumps and grease guns.

4. The grinding roller device of the mill needs to be replaced after using for more than 500 hours. When the grinding rolls are replaced, the rolling bearings in the sleeve must be cleaned.

5. According to the size of the material, soft and hard, water content, specific gravity, the processing thickness is also different. The analyzer of the mill, high speed, high fineness, low speed and low fineness can be adjusted. Increase the fineness and the output will be reduced accordingly. If the requirements are not met, the fan speed should be debugged and the user can flexibly master it.

6. The scrapping limit of the grinding roller ring of the mill, the remaining minimum wall thickness shall not be less than 10mm.

7. The feed should be stopped when the mill stops, and the main machine continues to grind. The motor of the main unit and the motor of the analyzer can be turned off to stop the grinding work after about one minute. After that, the blower motor is stopped to purge the remaining powder.

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE