- all

- product

- blog

- all

- product

- blog

Details

Raymond Roller Mill for Carbon

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

Raymond Roller Mill for Carbon

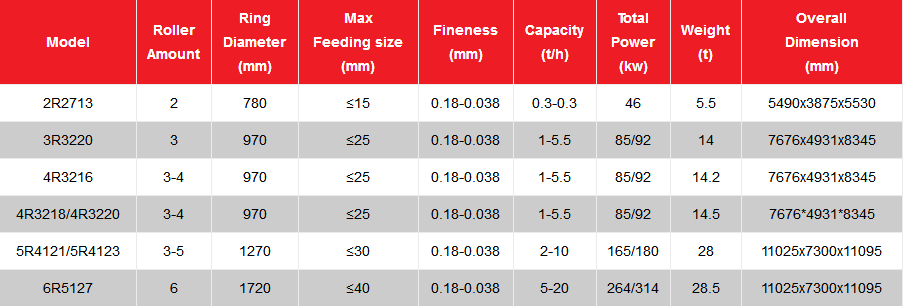

In the production line of carbon powder, the grinding mill for carbon has the advantages of high efficiency of grinding, good shape of finished products, excellent quality and obvious market competitiveness, which can improve the market competitiveness of carbon-powder manufacturers in the industry. In particular, the HC series vertical grinding mill produced by HC Milling (Guilin Hongcheng) has higher value in application and is applied in the field of carbon powder making. Because, its output is 30%-40% higher than that of traditional Raymond grinding mill and the cost of power consumption per unit can also be saved more than 30%. Therefore, it is the advanced equipment in the powder-making field of carbon.

Ⅰ. The advanced advantages

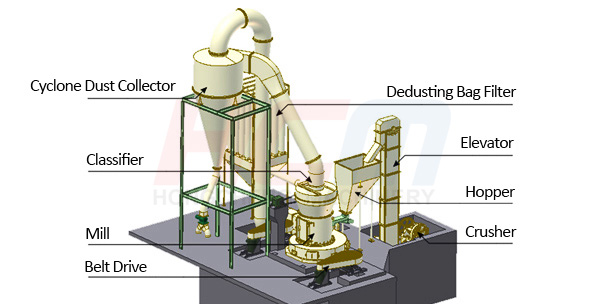

HC series pendulum grinding mill is a new type of Raymond grinding mill that has been successfully researched by HC Milling (Guilin Hongcheng). Our machines have been highly praised by peers and powder-making manufacturers thanks to many patented technologies, including the pendulum structure and maintenance-free grinding roller assembly, superfine classifier, high-efficiency and energy-saving dust removal system, easy-to-maintain transmission system, etc., which effectively ensures that various indicators of grinding technology in the process of grinding are greatly improved. So, this kind of grinding mill has become a truly high-yield, high-efficiency and easy-to-run grinding equipment.

In addition, this kind of machine is also a pioneer in the field of environmentally friendly grinding mill. The pulse-dust removal system, one of the patents, is adopted in the end-wind outlet of the grinding mill. This technology is popular in the field of power making and environmental protection. And many manufacturers try to imitate. What’s more, the filtration efficiency can reach more than 99.9% and the dust concentration of the outlet is<30mg/m3, which is better than the national standard.

The success of the machine also lies in the high efficiency of grinding, which can bring high-yield and high-efficiency effect to customers. Powders are classified by the forced turbine classifying system; therefore the fineness is uniform and fine. Besides, the size of finished product ranges from the original 80-325 mesh to 80-600 mesh. The wider the classifying range, the high the precision is. So, the demand of market and customer for powder making can be met, and the machine has become a best-selling product.

Ⅱ. Carbon grinding mill creates considerable market values for customers

This kind of grinding mill is similar to the vertical grinding mill, ultra-fine grinding mill and vertical grinding mill for slag produced by HC Milling (Guilin Hongcheng). All of them can bring efficient powder-making efficiency to the enterprise. The carbon powders processed by the HC series pendulum grinding mill is widely used in many fields, which reserves a strong strength for the development of the national economy. It can be widely used in graphite electrodes, carbon blocks, graphite anodes, carbon electrodes, pastes, electric carbons, etc. In the metallurgical industry, carbon can be widely used in the smelting of ferrous metals and non-ferrous metals and calcium carbide, phosphorus companies. In the medical world, carbon can also be used as medical carbon material for repairing or replacing damaged bone tissue.

With the advancement of science and technology and the development of society, the equipment can also develop in the direction of higher technology in the era of scientific and technological revolution, providing high-end and cutting-edge grinding technology and equipment for more non-metallic grinding and processing. With China’s economy entering the new normal, HC Milling (Guilin Hongcheng) under the development call insists on creating greater market value for customers with superior quality and first-class products and services, and continuously meets the growing market demand.

The daily inspection items of the milling machine:

1. Regularly listening to the normal operation sound of the mill and the classifier, and whether there is any abnormal sound.

2. Checking if the reducer and other equipment has any oil leakage, water leakage or material leakage.

3. Checking the wear of the tie rod seal every month.

4. Regularly check the function of the scraper and returning system.

5. Checking the pumping station every day, including: oil level of the fuel tank and refueling if necessary. The oil should be in accordance with the specified oil; check the pressure of each pressure gauge; check whether the filters are blocked.

6. Checking the oil return condition of the grinding roller lubrication station and whether the oil filling pressure is normal.

7. Always check the oil pipes and valves for oil leakage.

8. Measuring the wear of the grinding disc and the grinding roller liner each 1000H, and make a record.

9. Checking the pressure of the accumulator once a week.

10. Regularly check the center frame, nozzle ring, air guiding vane, water spray pipe and other grinding accessories.

Grinding Mill maintenance:

1. There should be a fixed person responsible for operation in using process, the operator must equipped with professional technical knowledge. Before the installation, the operator must carry out the necessary technical training to understand the principle performance of the mill and familiar with the operating procedures.

2. In order to keep the mill in good condition, the "safe operation system for equipment maintenance" should be established, and necessary maintenance tools as well as grease and corresponding accessories should be provided.

3. After using the grinding machine for a period of time, it should be repaired and maintained. Meanwhile, the wearing parts such as grinding rolls, grinding rings and blades should be repaired and replaced. The grinding roller device should be carefully check the connection bolt nut before use and after, see if there is looseness, whether the grease is sufficient. The refueling tools are available with manual refueling pumps and grease guns.

4. The grinding roller device of the mill needs to be replaced after using for more than 500 hours. When the grinding rolls are replaced, the rolling bearings in the sleeve must be cleaned.

5. According to the size of the material, soft and hard, water content, specific gravity, the processing thickness is also different. The analyzer of the mill, high speed, high fineness, low speed and low fineness can be adjusted. Increase the fineness and the output will be reduced accordingly. If the requirements are not met, the fan speed should be debugged and the user can flexibly master it.

6. The scrapping limit of the grinding roller ring of the mill, the remaining minimum wall thickness shall not be less than 10mm.

7. The feed should be stopped when the mill stops, and the main machine continues to grind. The motor of the main unit and the motor of the analyzer can be turned off to stop the grinding work after about one minute. After that, the blower motor is stopped to purge the remaining powder.

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE