- all

- product

- blog

- all

- product

- blog

Details

Raymond Mill for the Powder Making of White Carbon Black

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

Raymond Mill for the Powder Making of White Carbon Black

White carbon black serves as a kind of auxiliary that is environmentally friendly and with excellent properties. It is mainly used in fields such as rubber products, textiles, paper making, pesticides and food additives. As to rubber products, white carbon black mainly plays a role of reinforcing and filling. The properties of tread compound can be improved if white carbon black is added. For example, the tread compound can resist cut and tear. It is an inevitable development trend to replace the carbon black with white carbon black to improve the performance of the product. Manufacturers need to speed up the production process of white carbon black and reduce impurities of silicon gel. Therefore, for the manufacturers, technologically, in the future, they should make white carbon black that is high-dispersion and with low content of silica gel.

Grinding Mills manufactured by HC Milling (Guilin Hongcheng)can provide grinding equipment and technical support for white carbon black production enterprises. After decades of struggling, HC Milling (Guilin Hongcheng)has been committed to providing powder-processing enterprises with a full set of professional solutions. HC Milling (Guilin Hongcheng)can meet customer’s requirements for ultrafine powders with a fineness from 20 meshes to 3000 meshes. The output can be adjusted from 1 ton per hour to 80 tons per hour. The grinding mill has good performances such as stable operation, high efficiency, energy saving and low maintenance cost. After put into the market, it has received strong support and praise from customers. At present, it has been widely used and promoted in various powder-making industries all over the world.

#HC #HCMilling #GuilinHongcheng

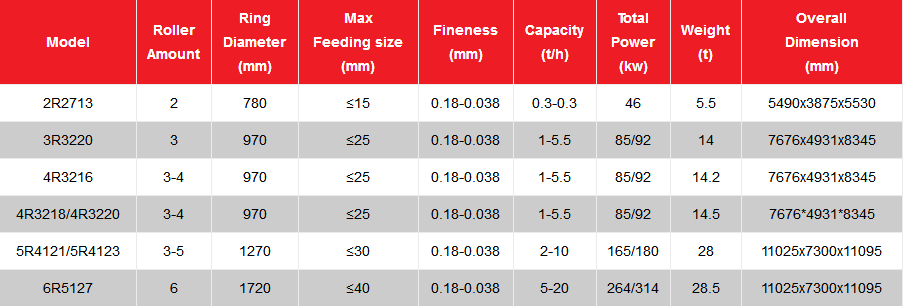

Roller number: 3-5

Maximum feeding size: 30mm

Output: 1-25t/h

Fineness of finished product : 0.022-0.18mm

Application range:

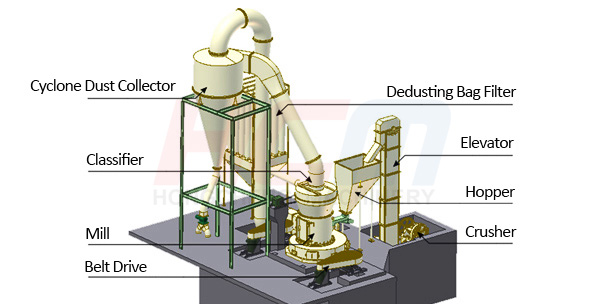

It can be widely used in fields such as metallurgy, chemical rubbers, coatings, plastics, pigments, inks, building materials, medicines, foods, etc. With high grinding efficiency and the high technology, it is ideal equipment for the processing of non-metallic minerals.

Application materials:

It is suitable for the processing of non-metallic minerals such as bauxite, titanium dioxide, ilmenite, phosphate rock, clay, graphite, calcium carbonate, barite, calcite, gypsum, dolomite and potash feldspar, etc. Fineness of finished product can be freely adjusted.

Features:

This kind of grinding mill effectively improves the per unit output of a single device and reduces the energy consumption. Additionally. It has the advantages of wide application, easy operation, easy maintenance, stable performance, high efficiency, environmental protection and high price-performance ratio, so its market is promising.

Thanks to covering many technological patents, the output of it can be increased by more than 40% and the cost of unit power consumption can be saved by more than 30% in contrast with the R-series grinding mill under the same power. It is a better choice to process 80-600 meshes powders due to a great improvement in various performances.

The daily inspection items of the milling machine:

1. Regularly listening to the normal operation sound of the mill and the classifier, and whether there is any abnormal sound.

2. Checking if the reducer and other equipment has any oil leakage, water leakage or material leakage?

3. Checking the wear of the tie rod seal every month.

4. Regularly check the function of the scraper and returning system.

5. Checking the pumping station every day, including: oil level of the fuel tank and refueling if necessary. The oil should be in accordance with the specified oil; check the pressure of each pressure gauge; check whether the filters are blocked.

6. Checking the oil return condition of the grinding roller lubrication station and whether the oil filling pressure is normal.

7. Always check the oil pipes and valves for oil leakage.

8. Measuring the wear of the grinding disc and the grinding roller liner each 1000H, and make a record.

9. Checking the pressure of the accumulator once a week.

10. Regularly check the center frame, nozzle ring, air guiding vane, water spray pipe and other grinding accessories.

Grinding Mill maintenance:

1. There should be a fixed person responsible for operation in using process, the operator must equipped with professional technical knowledge. Before the installation, the operator must carry out the necessary technical training to understand the principle performance of the mill and familiar with the operating procedures.

2. In order to keep the mill in good condition, the "safe operation system for equipment maintenance" should be established, and necessary maintenance tools as well as grease and corresponding accessories should be provided.

3. After using the grinding machine for a period of time, it should be repaired and maintained. Meanwhile, the wearing parts such as grinding rolls, grinding rings and blades should be repaired and replaced. The grinding roller device should be carefully check the connection bolt nut before use and after, see if there is looseness, whether the grease is sufficient. The refueling tools are available with manual refueling pumps and grease guns.

4. The grinding roller device of the mill needs to be replaced after using for more than 500 hours. When the grinding rolls are replaced, the rolling bearings in the sleeve must be cleaned.

5. According to the size of the material, soft and hard, water content, specific gravity, the processing thickness is also different. The analyzer of the mill, high speed, high fineness, low speed and low fineness can be adjusted. Increase the fineness and the output will be reduced accordingly. If the requirements are not met, the fan speed should be debugged and the user can flexibly master it.

6. The scrapping limit of the grinding roller ring of the mill, the remaining minimum wall thickness shall not be less than 10mm.

7. The feed should be stopped when the mill stops, and the main machine continues to grind. The motor of the main unit and the motor of the analyzer can be turned off to stop the grinding work after about one minute. After that, the blower motor is stopped to purge the remaining powder.

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE