- all

- product

- blog

- all

- product

- blog

Details

HC series pendulum mill

Hongcheng patented technology: new vertical pendulum structure. The technological revolution in the pendulum mill industry. The output of traditional Raymond mills is 30-40% higher than that of traditional Raymond mills.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

The HC vertical pendulum mill is a technical update based on the R-type mill. The technical indicators of this product have been greatly improved compared with the R-type mill. It is a new type of high-efficiency and energy-saving mill. The fineness of the finished product can be adjusted arbitrarily between 22-180μm (80-600 mesh). This product is an updated product of the R-type mill. Among them, the HC1700 large vertical pendulum mill is a large Raymond mill successfully developed early in China. The output is about 2.5 to 4 times higher than that of similar 5R equipment, which effectively increases the unit output of a single device and reduces the unit. Output and energy consumption are ideal for large-scale milling projects.

Fineness size: 22-180μm

Production capacity: 1-25t/h

This product is suitable for grinding limestone, calcite, activated carbon, talc, dolomite, titanium dioxide, quartzite, bauxite, marble, feldspar, barite, fluorite, gypsum, ilmenite, phosphate rock, clay, Graphite, clay, kaolin, diabase, coal gangue, wollastonite, lime, zircon sand, bentonite, manganese ore, etc. Various non-flammable and explosive materials with Mohs hardness below 7 and moisture within 6%.

ADVANTAGES AND FEATURES

New technology, spider-arm and pendulum grinding system with advanced and reasonable structure. The machine has very small vibration, low noise, stable mechanical operation and reliable performance. Through the practical application of the market, good social and economic benefits have been obtained.

New technology, spider-arm and pendulum grinding system with advanced and reasonable structure. The machine has very small vibration, low noise, stable mechanical operation and reliable performance. Through the practical application of the market, good social and economic benefits have been obtained.

The processing capacity of materials per unit grinding time is larger and the efficiency is higher. Under the condition that the total power of the R-type mill is unchanged, the output is increased by more than 40% year-on-year, and the unit power consumption cost is saved by more than 30%. It is a real high-efficiency and energy-saving mill product.

The remaining air outlet of the mill is equipped with a pulse dust collector, and its dust collection efficiency reaches 99.9%. All the positive pressure parts of the main machine are sealed, and a dust-free processing workshop is basically realized.

The remaining air outlet of the mill is equipped with a pulse dust collector, and its dust collection efficiency reaches 99.9%. All the positive pressure parts of the main machine are sealed, and a dust-free processing workshop is basically realized.

Adopting a new sealing structure design, the grinding roller device can be filled with grease once in 300-500 hours. In addition, there is no need to remove the grinding roller device to replace the grinding ring, which is more convenient for maintenance.

Adopting a new sealing structure design, the grinding roller device can be filled with grease once in 300-500 hours. In addition, there is no need to remove the grinding roller device to replace the grinding ring, which is more convenient for maintenance.

MILL STRUCTURE & WORKING PRINCIPLE

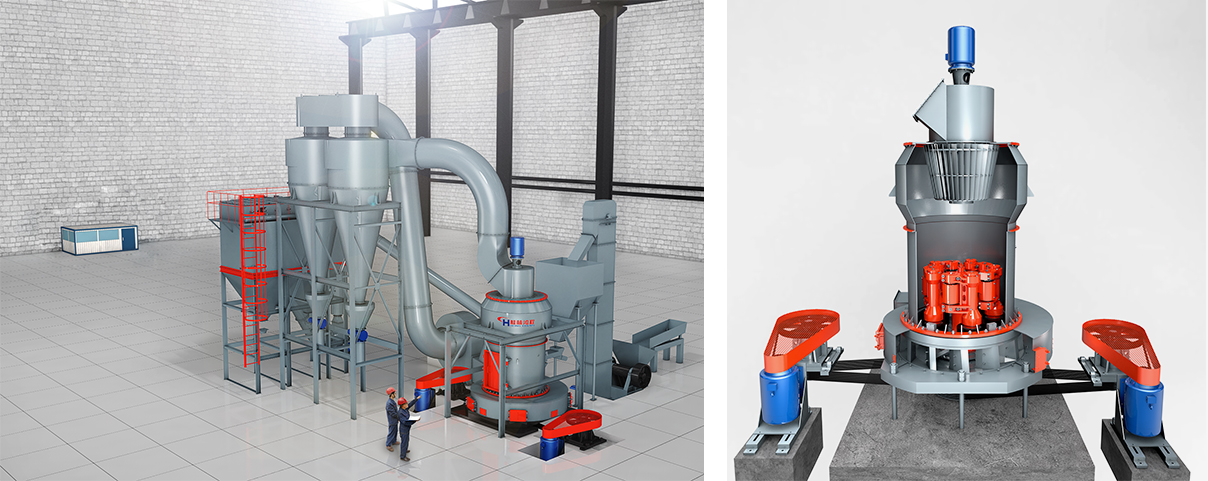

MILL STRUCTURE

The HC vertical pendulum mill is mainly composed of the main engine, feeder, classifier, blower, pipeline device, storage hopper, electric control system, collection system, etc. The main engine of the HC vertical pendulum mill is mainly composed of the base, the central shaft frame, the grinding ring, the plum blossom frame assembly, the grinding roller assembly, the central shaft, the blade holder, the blade holder assembly, and the cover tube. The grinding ring and grinding roller of the workpiece for rolling and grinding powder are made of wear-resistant materials by casting, and their contact surfaces with the materials are all subjected to wear-resistant treatment. The power unit of the system can adopt two modes: reducer drive and double drive. The classifier adopts a forced turbo classifier, and the conveying and feeding system can be selected according to different materials. The collection system can be a closed-circuit collection system with double cyclone and pulse dust collector and an open-circuit system with full pulse collection. The control system can choose automatic control and remote control modes according to customer needs.

WORKING PRINCIPLE

The material is crushed into the granularity that meets the specifications by the jaw crusher, and then lifted to the storage hopper by the bucket elevator, and then quantitatively sent to the main machine cavity by the feeder for grinding. The main machine cavity is supported on the plum blossom frame and the grinding roller device is around the center The shaft rotates, and the grinding roller swings outwards horizontally under the action of centrifugal force, so that the grinding roller presses the grinding ring, and the grinding roller rotates around the grinding roller shaft at the same time. The material raised by the rotating blade is thrown between the grinding roller and the grinding ring, and the grinding and grinding effect is achieved by the roller of the grinding roller. The ground powder is blown by the airflow of the blower to the classifier above the main engine for sieving. Those whose fineness is too coarse will still fall into the main machine for regrind, and those whose fineness meets the specifications will flow into the cyclone collector with the wind and be collected through the powder outlet The discharge is the finished product (the particle size of the finished product can be as high as 0.008mm). The purified airflow flows into the blower through the pipe at the upper end of the cyclone. The air path is cyclic. Except for the positive pressure from the blower to the grinding chamber, the airflow in the remaining pipelines is at negative pressure The indoor sanitary conditions are better. Since the moisture in the material is heated and evaporated into gas during grinding, the gas leaking into the air duct at the joints of the flanges and the inlet in the pipeline causes the air volume in the circulating air path to increase. These increased air volumes are passed through the blower and The remaining pipe between the hosts is led to a simple collector, and the powder brought in with the wind flow is collected and discharged from the ash hopper.

TECHNICAL DATA

| Model | Roller Number |

Roller Diameter (mm) |

Ring Diameter (mm) | Max. Feeding Size (mm) | Fineness (mm) | Capacity (t/h) |

Main Motor Power (kw) |

Blower Power (kw) |

Classifier Motor Power (kw) |

| HC1000 | 3 | 320 |

1000 | ≤25 | 0.022-0.18 | 1-6.5 | 45 |

45 |

11 |

| HC1300 | 4 | 410 |

1300 | ≤30 | 0.038-0.18 | 2-12 | 90 | 90 | 15 |

| HC1500 | 4 | 460 | 1500 | ≤30 | 0.038-0.18 | 3-15 | 132 | 132 | 22 |

| HC1700 | 5 | 510 | 1700 | ≤30 | 0.038-0.18 | 6-25 | 160 | 160 | 22 |

Note:

1.The Models above can be equiped with Hongcheng patented certical pendulum sturcture,suspension pendulum structure is also avaible to material character and product fineness.

2.The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

MATERIAL PROCESSING

Guilin Hongcheng pulverizing equipment is used in large-scale non-metallic mineral pulverizing, environmentally friendly desulfurized limestone pulverizing, calcium carbonate pulverizing, large-scale pulverized coal equipment, petroleum coke fuel industry, manganese ore processing, slag, water slag, and comprehensive utilization of fly ash , Gypsum powder and many other fields.

Coal Petroleum coke Slag Cement clinker

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE