- all

- product

- blog

- all

- product

- blog

Details

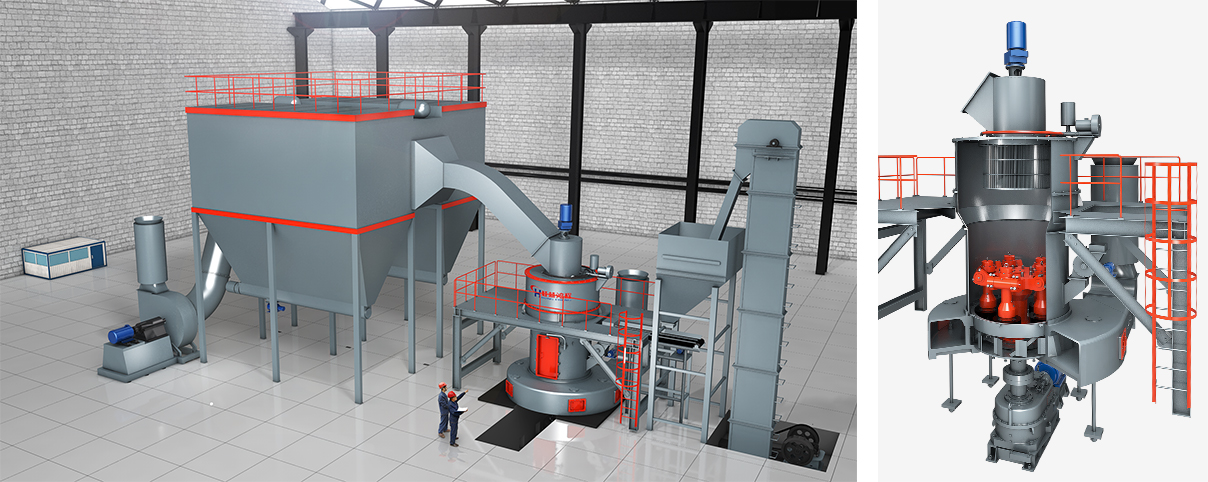

HC Super large Calcium Carbonate production line

Guilin Hongcheng, a professional grinding mill manufacturer, has independently developed super large pendulum grinding mill in Asia, HC3000.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

HC super large grinding mill is an innovative product based on HC1700 pendulum grinding mill. It can be widely used in powder processing of medicinal materials and food with mohs hardness below 7 and moisture within 6%. The fineness can be adjusted between 38 and 180μm. HC large pendulum mill, the output can be up to 90T/h.

ADVANTAGES AND FEATURES

New type of spide-arm featured in compact structure. It can be maintained without disassembly, which save the maintenance time.

New type of spide-arm featured in compact structure. It can be maintained without disassembly, which save the maintenance time.

Adopt maintenance-free oil seal technology, screw seal and skeleton oil seal multi-layer barrier, limited to prevent dust from entering, can achieve add lubricating oil per 500~800 hours, reduce the maintenance cost.

Adopt maintenance-free oil seal technology, screw seal and skeleton oil seal multi-layer barrier, limited to prevent dust from entering, can achieve add lubricating oil per 500~800 hours, reduce the maintenance cost.

Unique high chromium alloy material technology, the use time is nearly 3 times of the industry standard.

Unique high chromium alloy material technology, the use time is nearly 3 times of the industry standard.

Forced turbine classification technology. The particle size of finished products can be adjusted infinitely between 80~400 mesh.

Forced turbine classification technology. The particle size of finished products can be adjusted infinitely between 80~400 mesh.

Off-line pulse dust collection system, dust collection rate up to 99.9%.

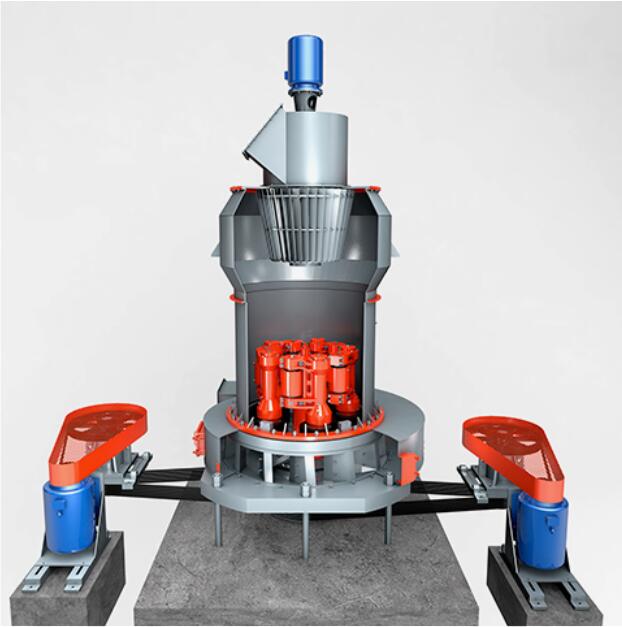

MILL STRUCTURE

HC grinding mill consists of mill system, classifying system, screening, collecting system and other components. The mill system adopts the structure of integral casting base, which can be used as shock absorbing foundation. The classifying system adopts mandatory turbine classifier structure and the collecting system adopts pulse collection.

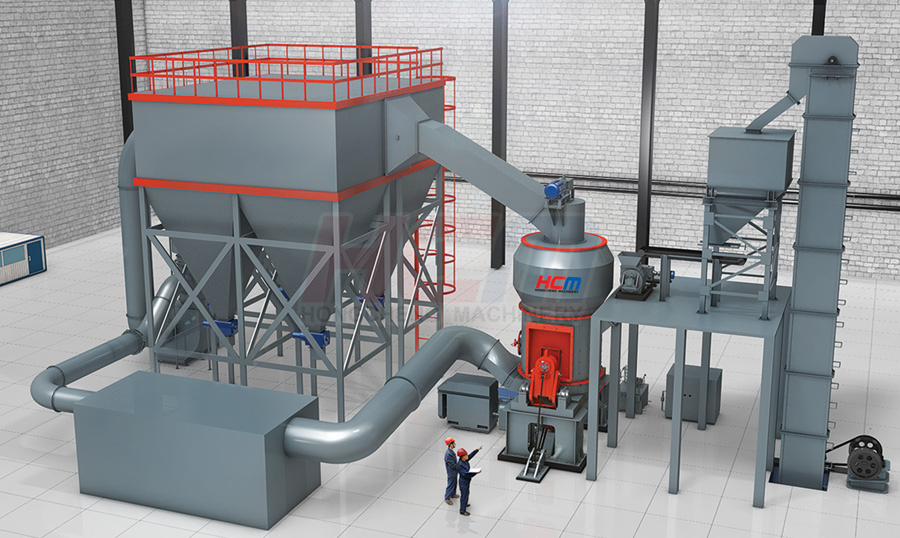

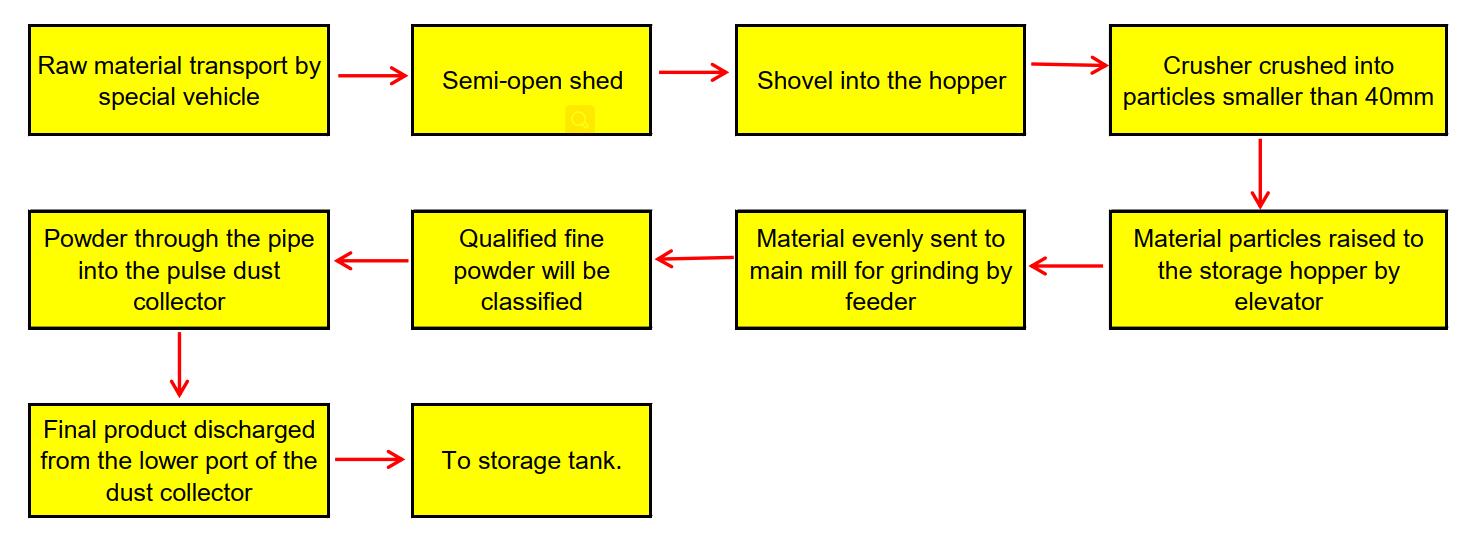

WORKING PRINCIPLE & PROCESS

Power processing system technological process: raw material will be transport to semi-open shed by special vehicle, and then be shoveled into the crusher to be crushed into particles smaller than 40mm. The material particles will be raised to the storage hopper by the elevator and then be evenly sent to the main mill for grinding by feeder. The qualified fine powder will be classified and blew to the pulse dust collector as product and finally discharged from the dust collector. The product will be transported to powder storage. HC super large grinding mill has really high capacity so the product cannot be packed by hand-filling, the packing job is supposed to be done after the power be sent to storage tank.

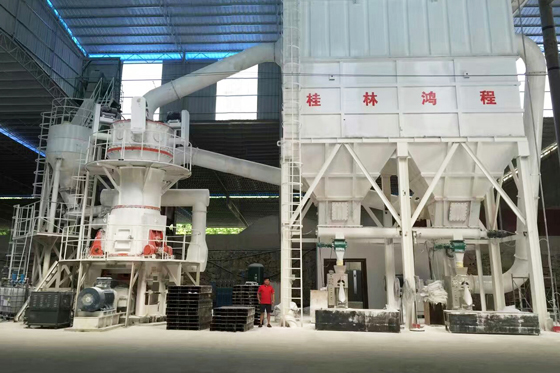

SUCCESSFUL CASES

Southeast Asia Calcium Carbonate Line Superfine Calcium Carbonate Project

OTHER RELATED RECOMMENDATIONS

TECHNICAL DATA

| Model | Roller No. | Ring Diameter(mm) | Max. Feeding Size (mm) | Fineness (mm) | Capacity (t/h) | Total Power (kw) |

| HC1900 | 5 | 1900 | 40 | 0.038-0.18 | 10-35 | 555 |

| HC2000 | 5 | 2000 | 40 | 0.038-0.18 | 15-45 | 635-705 |

| HC2500 | 6 | 2500 | 40 | 0.038-0.18 | 30-60 | 1210 |

| HC3000 | 6 | 3000 | 40 | 0.038-0.18 | 45-90 | 1732 |

Note:

1. The Models above are equiped with newly designed spider-arm structure.

2. The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE