- all

- product

- blog

- all

- product

- blog

Details

PHOSPHORITE POWDER PROCESS SOLUTIONS VERTICAL MILLING MACHINES FOR SALE

Phosphorus is an important element of biological cytoplasm and an essential element for plant growth. 84% to 90% of the world's phosphate rock is used to produce various phosphate fertilizers, 3.3% to produce feed additives, and 4% to produce detergents. Phosphorus powder is widely used, and the appropriate mill can be selected according to the fineness of the finished product.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

Phosphorus is an important element of biological cytoplasm and an essential element for plant growth. 84% to 90% of the phosphate rock in the world is used for the production of various phosphate fertilizers, 3.3% for the production of feed additives, 4% for the production of detergents, and the rest for chemical, light industry, national defense and other industries. Phosphate rock is also an important chemical mineral raw material. Part of the phosphate rock is used to produce pure phosphorus (yellow phosphorus, red phosphorus) and chemical raw materials, and a small amount is used as animal feed. Phosphorus powder is widely used, and the appropriate mill can be selected according to the fineness of the finished product.

PHOSPHORITE POWDER PROCESS SOLUTIONS VERTICAL MILLING MACHINE is an energy-saving advanced grinding equipment that integrates drying, grinding, grading, and conveying, developed by Guilin Hongcheng through learning and introducing advanced foreign technology, and after more than 20 years of painstaking research and development.

VERTICAL MILLING MACHINE has the advantages of high grinding efficiency, low power consumption, large feeding size, easy adjustment of product fineness, simple equipment process flow, small footprint, low noise, low dust, easy use and maintenance, Advantages of low operating cost and low consumption of wear-resistant materials. It can be applied to the grinding process of limestone.

The HLM PHOSPHORITE POWDER PROCESS SOLUTIONS can grind materials with moisture 20% to 30% to moisture less than 1%, and is highly adaptable to materials. The product fineness can be adjusted from 2-5mm to 15μm with a pass rate of 97%.

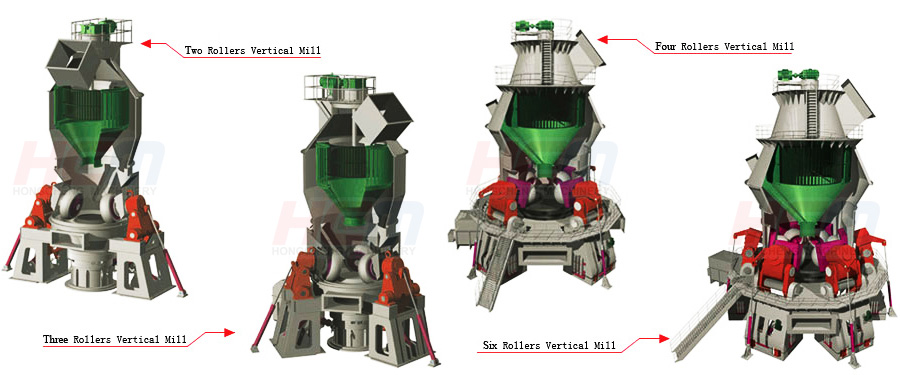

Main machine section structure

The HLM vertical mill adopts a standard modular design to manufacture a pressurizing device. As the capacity of the mill increases, the number of grinding rollers is correspondingly increased (2, 3, 4 or 6 grinding rollers can be used), and the arrangement is combined to compare Few standard module parts, forming a series of products with multiple capabilities, meeting the requirements of different material processing and different product fineness and output.

ADVANTAGES AND FEATURES

1. Low overall investment cost

It integrates crushing, drying, grinding, grading, and conveying. The process flow is simple, the system equipment is small, the structure is compact, and the area is small, which is 50% of the ball mill. It can be laid out in the open air and the construction cost is low, which directly reduces the investment of the enterprise cost.

2. High grinding efficiency

The grinding efficiency is high and the energy consumption is low. Compared with the ball mill, the energy consumption is 40%-50% lower; the single machine has a large production capacity and can use low power.

3. Convenient maintenance and low operating cost

The grinding roller can be turned out of the machine with a hydraulic device. The replacement of the roller sleeve liner and the grinding machine have a large maintenance space, and the maintenance operation is very convenient; the grinding roller sleeve can be turned over and used, which extends the service life of wear-resistant materials; The cloth can be loaded, and the mill can be started without load, eliminating the trouble of starting up; low wear, grinding roller, grinding disc liner using special materials, long life.

4. Stable product quality

The material stays in the mill for a short time, which is easy to detect the particle size distribution and chemical composition of the product, reduces repeated grinding, and the product quality is stable; the product has uniform particle shape, narrow particle size distribution, good fluidity, and strong product adaptability; The iron content is very small, and the mechanically worn iron contained is easy to remove. When used for grinding white or transparent materials, the product has high whiteness and purity

MILL STRUCTURE

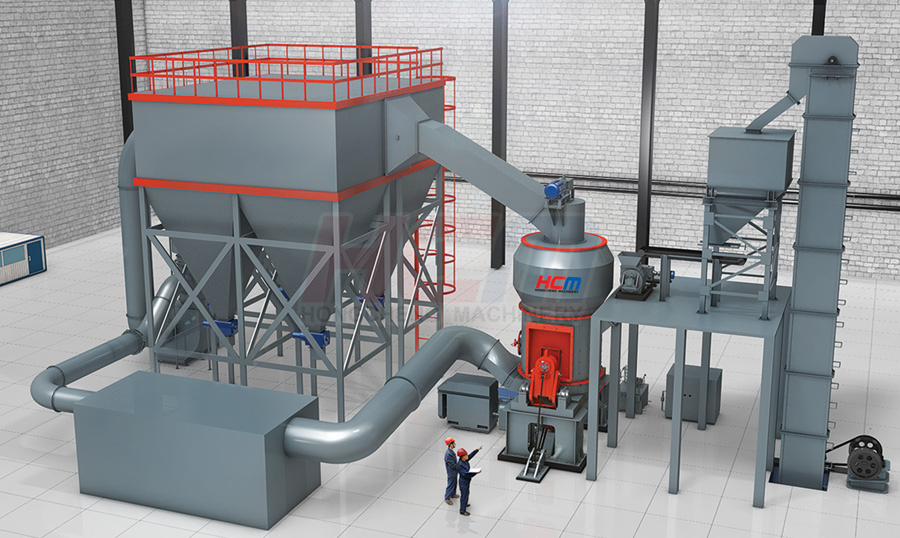

HLM PHOSPHORITE POWDER PROCESS SOLUTIONS VERTICAL MILLING MACHINE is mainly composed of main machine, feeder, classifier, blower, pipeline device, storage hopper, electric control system, collection system, etc.

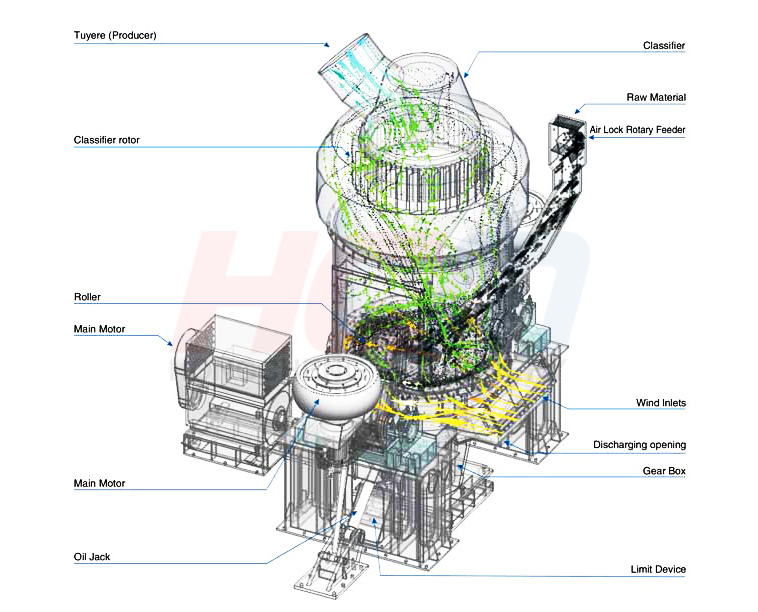

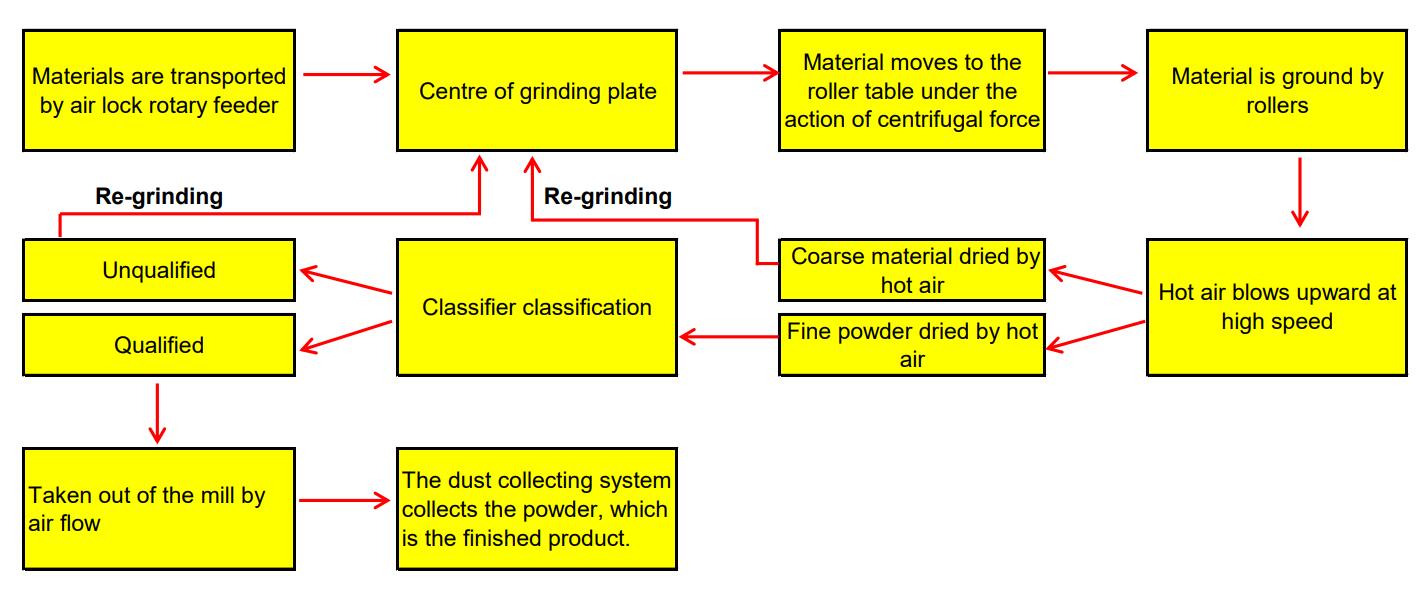

WORKING PRINCIPLE

The motor drives the reducer to drive the grinding disc to rotate, and the material to be ground is fed into the center of the rotating grinding disc by the lock air feeding equipment. Under the action of centrifugal force, the material moves to the periphery of the grinding disc and enters the grinding roller table. Under the action of the roller pressure, the material is crushed by squeezing, grinding and shearing.

PHOSPHORITE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of limestone are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of limestone are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model |

Grinding Table Metian Diameter (mm) |

Capacity (t/h) |

Raw Material Moisture (%) |

Raw Meal Fineness | Raw Meal Moisture (%) |

Power (k/w) |

| HLM30/2 | 2500 | 85-100 | <10% | R0.08<12% | ≤1% | 800/900 |

| HLM34/3 | 2800 | 130-160 | <10% | R0.08<12% | ≤1% | 1120/1250 |

| HLM42/4 | 3400 | 190-240 | <10% | R0.08<14% | ≤1% | 1800/2000 |

| HLM44/4 | 3700 | 240-300 | <10% | R0.08<14% | ≤1% | 2500/2800 |

| HLM50/4 | 4200 | 320-400 | <10% | R0.08<14% | ≤1% | 3150/3350 |

| HLM53/4 | 4500 | 400-500 | <10% | R0.08<14% | ≤1% | 3800/4200 |

| HLM56/4 | 4800 | 440-550 | <10% | R0.08<14% | ≤1% | 4200/4500 |

| HLM60/4 | 5100 | 550-670 | <10% | R0.08<14% | ≤1% | 5000/5400 |

| HLM65/6 | 5600 | 600-730 | <10% | R0.08<14% | ≤1% | 5600/6000 |

Note: Raw Materials bond index ≤13KWH/T

SUCCESSFUL CASES

HLM2000 PHOSPHORITE PRODUCTION LINE

Equipment configuration: 1 HLM2000

Processing material: Phosphorite

Fineness: 100 mesh

Production: 55 t/h

Location: Yunnan

RECOMMEND LIMESTONE GRINDING MILL

HLMX SUPERFINE VERTICAL MILL HC SUPER LARGE GRINDING MILL HCQ REINFORCED GRINDING MILL

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE