- all

- product

- blog

- all

- product

- blog

Details

SUPER FINE CALCIUM OXIDE POWDER PRODUCTION GRINDING MILL OPERATION LINE FACTORY PRICE

HLMX ultra-fine vertical mill, breaking through the bottleneck of ultra-fine powder processing, ideal equipment for large-scale production of ultra-fine powder processing.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

Calcium oxide is also called quicklime, calcined lime, and calcined lime. Calcium oxide is an inorganic compound. Most of its surface is white powder. The impurities contained in it are light yellow or gray. It is hygroscopic. After processing, it is widely used in metallurgy, building materials, cement, non-metallic minerals and other industries. There are many types of calcium oxide mills. Manufacturers will produce various types of equipment according to the needs of most users, and their production capacity and fineness are different, and the performance is also very different, and the price will also vary. Therefore, when users are purchasing equipment, they must choose equipment models according to their own needs.

1. It can be used as a filler, for example: used as a filler for epoxy adhesives;

2. Used as an analytical reagent, as a carbon dioxide absorbent during gas analysis, as a spectrum analysis reagent, high-purity reagents are used in the epitaxy and diffusion process in semiconductor production, the drying of laboratory ammonia and alcohol dehydration, etc.

3. As raw materials, it can be used to produce calcium carbide, soda ash, bleaching powder, etc., and also used in leather making, waste water purification, calcium hydroxide and various calcium compounds;

4. It can be used as building materials, metallurgical fluxes, cement accelerators, and fluxes for phosphors;

5. Used as vegetable oil decolorizer, drug carrier, soil conditioner and calcium fertilizer;

6. It can also be used for refractory materials and desiccants [1];

7. It can be used to prepare agricultural machinery No. 1 and No. 2 glues and underwater epoxy adhesives, and also used as a reactant for pre-reaction with 2402 resin;

8. Used for acid wastewater treatment and sludge conditioning;

9. It can also be used as a boiler shutdown protective agent, using the moisture absorption capacity of lime to keep the metal surface of the boiler water vapor system dry to prevent corrosion. It is suitable for long-term shutdown protection of low-pressure, medium-pressure, and small-capacity drum boilers;

10. It can react with water to prepare calcium hydroxide. The reaction equation is: CaO+H₂O=Ca(OH)₂, which is a compound reaction.

There are more and more applications for ultra-fine powder, and traditional ultra-fine powder processing equipment has low capacity and cannot meet the requirements of large-scale production. Guilin Hongcheng HLMX series SUPER FINE CALCIUM OXIDE POWDER PRODUCTION GRINDING MILL OPERATION LINE is a large-scale high-fine vertical pulverizer developed based on technology from Germany, Japan and Taiwan, which is suitable for the development needs of my country's non-metallic mining industry. HLMX series ultra-fine marble powder vertical mill adopts dynamic and static combined classifier, the product fineness can be adjusted between 7μm~45μm. Using a secondary classification system, the fineness can be as high as 3μm. This product can be used for the processing of calcium oxide superfine powder. High efficiency, high yield, environmental protection and energy saving are the characteristics of our products.

Finished product size: 3-45μm

Production capacity 4-40t/h

ADVANTAGES AND FEATURES

|

|

|

|

|

Easy maintenance and low operating cost. The grinding roller can be turned out of the mill with a hydraulic device to replace the roller sleeve liner. The roller sleeve can be turned over and used. HLMX series mills can be started without load. The grinding roller and the grinding disc liner are made of special materials and have a long service life. |

|

|

|

|

|

Environmental protection. The whole HLMX vertical mill system has low vibration and low noise.The whole system is sealed and operates under full negative pressure without dust overflow. |

|

|

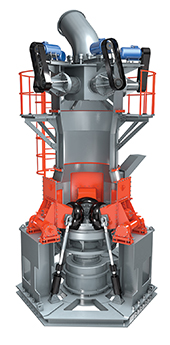

MILL STRUCTURE

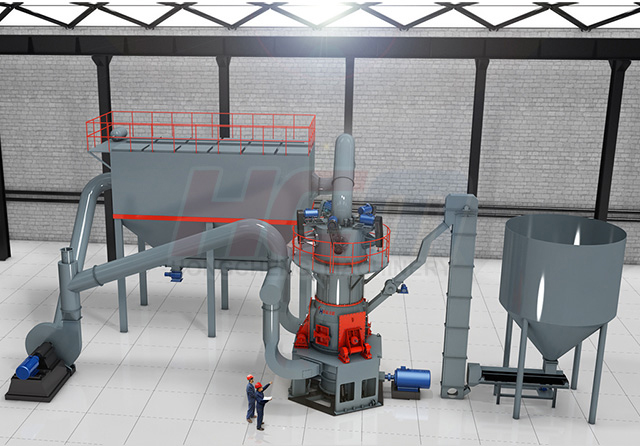

The complete system of HLMX series calcium oxide powder production line is mainly composed of main machine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc.

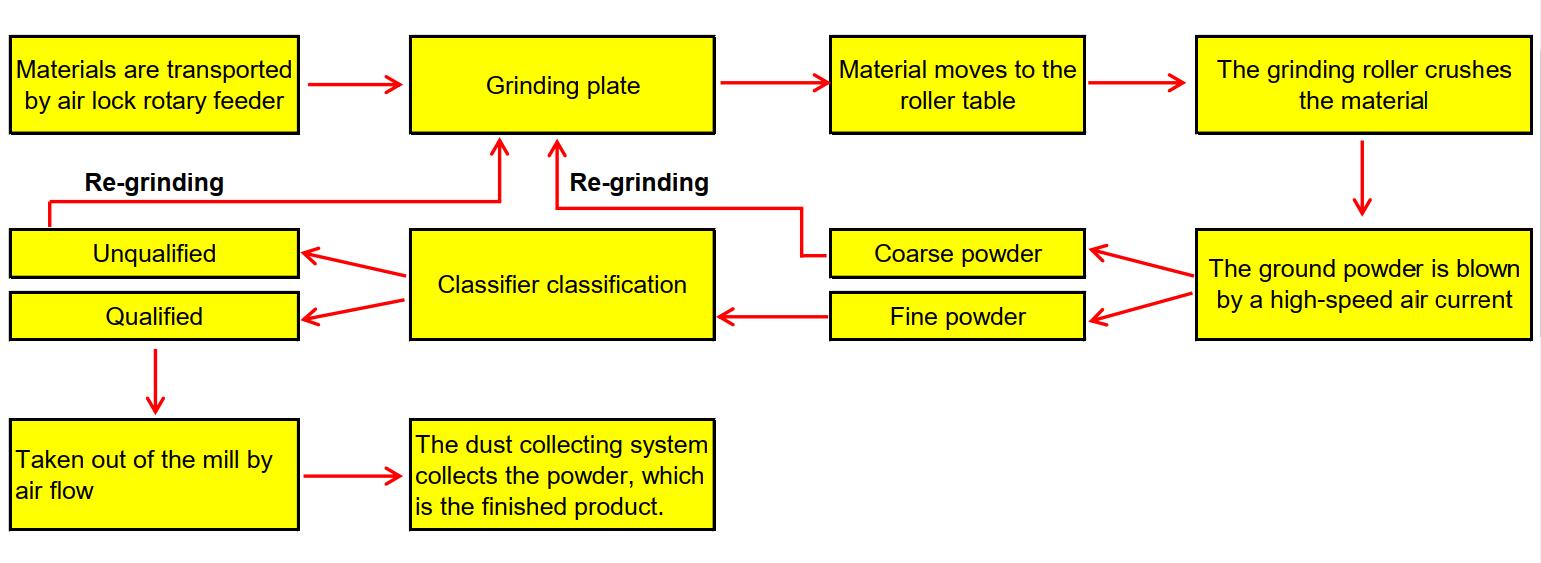

WORKING PRINCIPLE

The motor drives the reducer to drive the grinding disc to rotate. The material to be grinded is sent to the center of the rotating grinding disc by the locking air feeding equipment. Under the action of centrifugal force, the material moves to the periphery of the grinding disc and enters the grinding roller table. Under the action of grinding roller pressure, the material is crushed by extrusion, grinding and shearing.

When iron and other sundries mixed with materials move to the edge of the grinding disc, they cannot be blown by the wind due to their own weight and fall into the lower cavity of the mill and are scraped into the slag discharge mouth by the scraper for discharge.

SECONDARY CLASSIFYING SYSTEM

The secondary classification system consists of superfine classifier, fan, dust collector, hopper, screw conveyor, pipe and other equipment. The ultrafine classifier is its core equipment. HLMX series superfine vertical mill is equipped with secondary air separation grading system, high powder efficiency, can effectively separate coarse powder and fine powder, separation fineness can be up to 3 μm, can achieve a vertical mill production of different specifications of products, but also fast and stable production of the same fineness of products.

FEATURES OF THE SECONDARY CLASSIFYING SYSTEM

High classification efficiency: the classifier and fan adopt frequency conversion speed regulation control. By adjusting the speed of the classifier and fan impeller, the fineness of finished products with different specifications can be obtained quickly, and the classification efficiency is high.

Classifier: An efficient and energy - saving classifier. Single rotor and multi – rotor can be used, fineness can be adjusted.

Big range of product fineness: Fine particles of vertical grinding materials can be separated, and the fineness range of separation is from 3um to 45um.

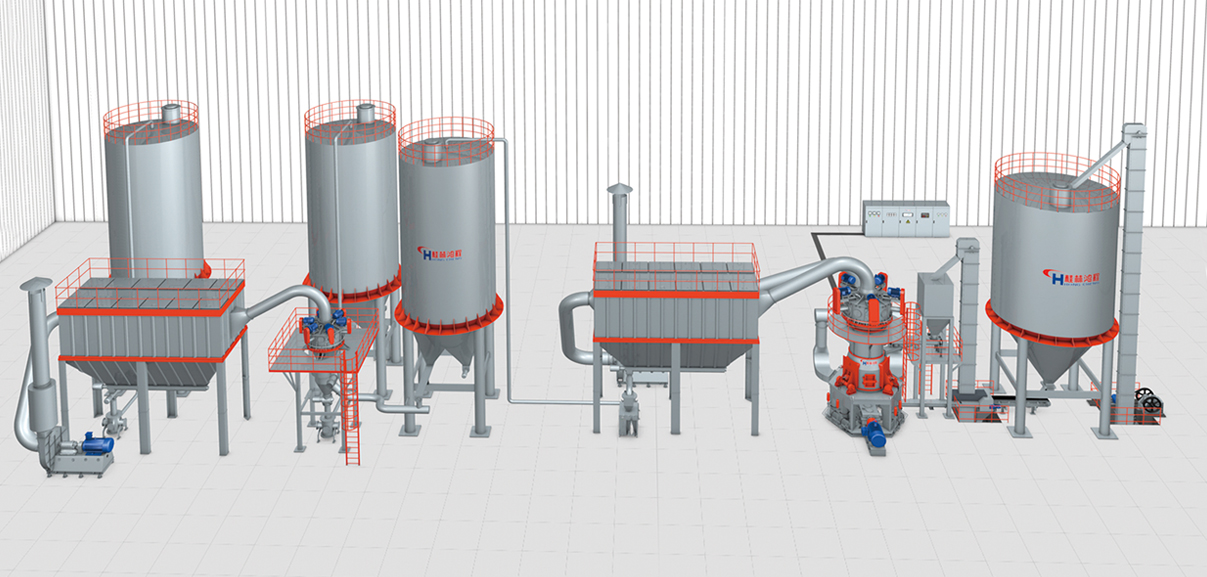

CALCIUM OXIDE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

Large pieces of marble and calcium oxide are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed marble and calcium oxide pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and then returned to the host for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model |

Roller Number |

Roller Diameter (mm) |

Ring Inner Diameter (mm) |

Material Moisture |

Fineness (mm) |

Capacity (t/h) |

Blower Power (KW) |

Classifier Power(KW) |

Main Motor Power (KW) |

| HLMX1000 | 3 | 800 | 1000 | ≤5% |

0.045mm-0.01mm 0.005mm (with secondary classifier) |

3-12 | 132 | 15 | 185 |

| HLMX1100 | 3 | 880 | 1100 | ≤5% | 4-14 | 200 | 150 | 250 | |

| HLMX1300 | 3 | 1000 | 1300 | ≤5% | 5-16 | 250 | 180 | 280 |

Note:

The actual production capacity depends on the materials being processed. The above mentioned data is just for a reference.

SUCCESSFUL CASES

CHINA CUSTOMIZED SUPER MICRON GRINDING MILL MACHINE PROJECT

Equipment model and number: 1 HLMX1100 high-fine vertical mill

Processing material: calcium oxide

Finished product fineness: 325-1500 mesh

Equipment output: 325 mesh D97 output 15-18T/h;

600 mesh D97 output 10-12T/h;

800 mesh D97 output 8-10T/h.

OTHER RELATED GRINDING MILL RECOMMENDATIONS

MARBLE MICRO POWDER TECH SOLUTIONS GRINGDER ULTRAFINE GRINDER RAW VERTICAL TURBINE TYPE POWDERY QUALITY CALCIUM OXIDE GRINDING MILL

MILL SUPPLIER GRINDING MILL FACTORY EQUIPMENT QUOTATION

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE