- all

- product

- blog

- all

- product

- blog

Details

GROUND ACTIVATED CARBON PRODUCERS RAYMOND POWDER MAKING MACHINE PRICE

The HCQ series mill is a new type of milling equipment based on the R series pendulum mill. Activated carbon has the characteristics of developed pore structure, large specific surface area and smooth surface, so ordinary milling equipment is not suitable for pulverizing activated carbon. The output of traditional Raymond mills is very low, and activated carbon is particularly light and easy to enter Raymond. The grinding roller assembly increases the maintenance cost. Aiming at the characterist

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

The main raw material of activated carbon can be almost all carbon-rich organic materials, such as coal, wood, fruit shell, coconut shell, walnut shell and so on. Activated carbon has the characteristics of developed pore structure, large specific surface area and smooth surface, so ordinary milling equipment is not suitable for pulverizing activated carbon. The output of traditional Raymond mills is very low, and activated carbon is particularly light and easy to enter Raymond. The grinding roller assembly increases the maintenance cost. Aiming at the characteristics of activated carbon, the activated carbon mill produced by Guilin Hongcheng changed the original material of the wearing parts such as the roller bearing seal and the roller grinding ring to make it difficult to enter dust and damage.

The HCQ series GROUND ACTIVATED CARBON PRODUCERS is a new type of milling equipment based on the R series Raymond mill. The modified product is suitable for grinding activated carbon and other non-flammable and explosive materials with Mohs hardness below 7 and humidity within 6%. The fineness of the finished product can be adjusted arbitrarily between 39~180μm (80~400 mesh). HCQ series is an updated product of R-type mill (traditional Raymond mill).

Finished product size: 38-180μm

Production capacity: 2-13t/h

ADVANTAGES AND FEATURES

![]()

Use the maintenance-free grinding roller assembly and a new spider-arm, the equipment has higher operating reliability and convenient maintenance.

![]()

A new big blade is used to send a large amount of material between the grinding roller and the grinding ring for grinding.

![]()

High output capacity: HCQ series is improved on the basis of the R-type grinding mill, the system is upgraded, the configuration is more reasonable, and the output capacity is higher.

![]()

High classification accuracy: The classifier adopts a built-in large blade cone turbine classifier, and the particle size of the finished product can be adjusted from 80 mesh to 400 mesh.

![]()

Large conveying capacity: The blower adopts a high-pressure centrifugal fan, and the air volume and pressure are increased, which greatly improves the pneumatic conveying capacity.

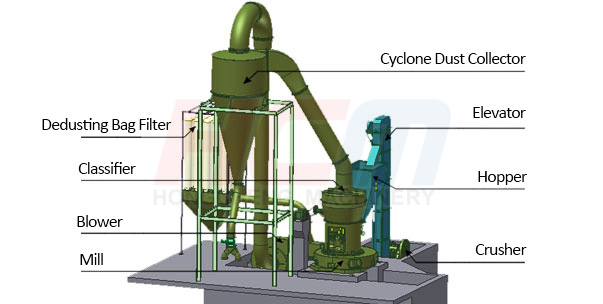

MILL STRUCTURE

Structure of the HCQ activated carbon Raymond powder making machine is mainly composed of base, central shaft frame, grinding ring, spider-arm, grinding roller assembly, central shaft, blade holder, blade base assembly, and cover tube. The grinding ring and grinding roller are casted from wear-resistant materials, and their contact surfaces with the materials are all subjected to wear-resistant treatment.

The power unit can adopt two modes: reducer drive and double belt drive. The classifier adopts a forced turbo classifier, and the conveying and feeding system can be selected according to different materials. The collection system can be a closed-circuit collection system with double cyclones and pulse dust collector and an open-circuit system with full pulse collection. The control system can choose automatic control and remote control modes according to customer needs.

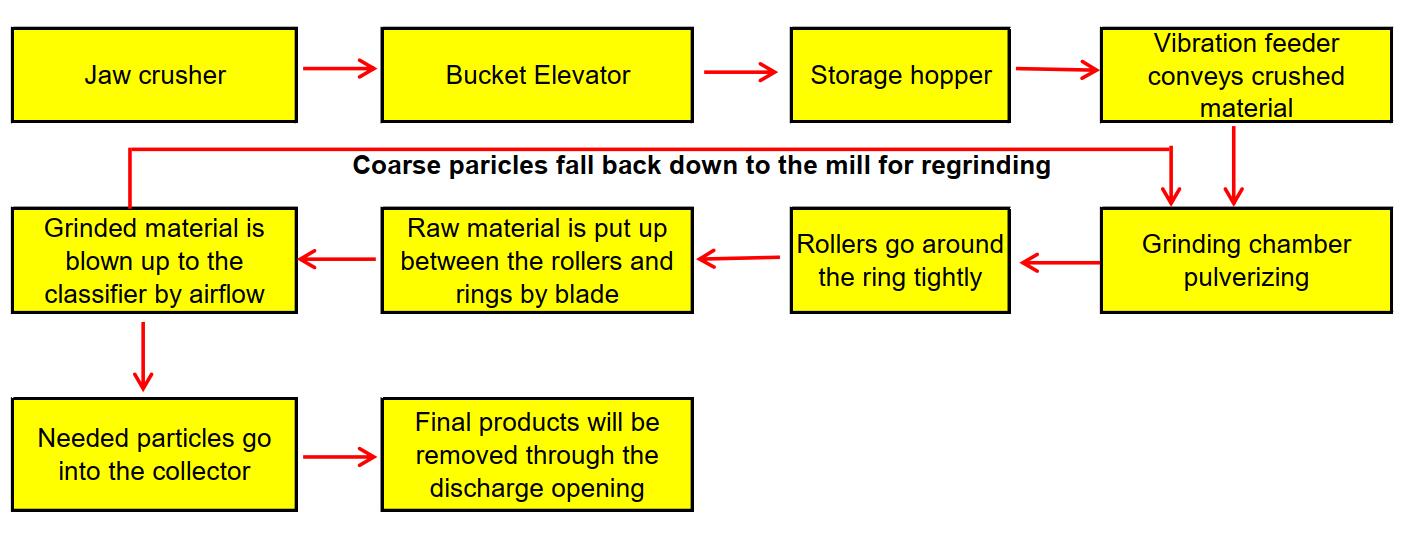

WORKING PRINCIPLE

Material is broken by jaw crusher firstly into required size, which are carried by bucket elevator up to storage hopper, again by feeder quantitative into host cavity for grinding, host cavity support in the plum flower rack roller device rotation around the center axis, roller under the action of centrifugal force, horizontal swing outward, so that the roller compaction of ring, roller grinding roller rotation around at the same time.

ACTIVATED CARBON POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of activated carbon are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of activated carbon are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Number |

Roller Diameter (mm) |

Ring Inner Diameter (mm) |

Ring Number |

Main Motor Power (kw) |

Blower Power (kw) |

Classifier Motor Power (kw) |

| HCQ1290 | 3 | 370 |

1170 | 1 | 75 |

75 | 15 |

| HCQ1500 | 4 | 450 |

1500 |

1 | 110 | 110 | 22 |

Note:

1.The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

2. The pulse dust collector is not a standard configuration and can be selected according to environmental protection requirements.

SUCCESSFUL CASES

Equipment model and number: 1 set HCQ1500

Processing material: Activated Carbon

Finished product fineness: 200 mesh

Equipment output: 4.5t/h

OTHER RELATED GRINDING MILL RECOMMENDATIONS

CUSTOMIZED ACTIVATED CARBON EQUIPMENT ULTRAFINE BUY BEST SELLING ADVANCE ACTIVATED CABON RAYMOND CHINA CHEAP LARGE CAPACITY ACTIVATED CARBON

CUSTOMIZED ACTIVATED CARBON EQUIPMENT ULTRAFINE BUY BEST SELLING ADVANCE ACTIVATED CABON RAYMOND CHINA CHEAP LARGE CAPACITY ACTIVATED CARBON

GRINDING MILL MANUFACTURERS MILL GRINDER FROM CHINA PENGULUM ROLLER VERTICAL MILL

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE