- all

- product

- blog

- all

- product

- blog

Details

BARITE RAYMOND GRINDING MILL CHINA COMPLETE EQUIPMENT MANUFACTURER

Barite is a non-metallic mineral product with barium sulfate (BaSO4) as the main component, with a Mohs hardness of 3 to 3.5. Barite is chemically stable, insoluble in water and hydrochloric acid, non-magnetic and toxic, and can absorb X-rays and γ- rays. Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

① Drilling mud weighting agent: In some oil and gas well drilling, adding barite powder to the mud is an effective measure to increase the proportion of mud, and it is the most commonly used measure in drilling operations that can effectively avoid frequent blowout accidents.

② Lithopone pigment: heating barium sulfate, using a reducing agent to reduce to barium sulfide (BaS), and then reacting with zinc sulfate (ZnSO4) to obtain a mixture of barium sulfate and zinc sulfide (BaSO4 accounts for 70%, ZnS accounts for 30%) %) is the lithopone pigment. It can be used as a raw material for paints and painting pigments. It is a commonly used high-quality white pigment.

③ Various barium compounds: Barium oxide, barium carbonate, barium chloride, barium nitrate, precipitated barium sulfate, barium hydroxide and other chemical raw materials can be produced with barite as raw material.

④ Used in industrial fillers: In the paint industry, barite powder filler can increase the thickness, strength and durability of the paint film. In the fields of paper, rubber, and plastics, barite can improve the hardness, abrasion resistance and aging resistance of rubber and plastics; lithopone pigments are also used to make white paints, which are more used indoors than lead white and magnesium white The advantages.

⑤ Mineralizer for cement industry: The use of barite and fluorite composite mineralizer in cement production has obvious effects on promoting the formation of C3S and activating C3S, and the quality of clinker has been improved.

⑥ Anti-ray cement, mortar and concrete: Barite is used to absorb X-rays, and barite is used to make barium cement, barite mortar and barite concrete to replace metal lead plates to shield nuclear reactors and build scientific research , X-ray-proof buildings in hospitals.

⑦ Road construction: The mixture of rubber and asphalt containing about 10% barite has been successfully used in parking lots and is a durable paving material.

⑧ Others: barite and oil are blended and coated on cloth to make tarpaulin; barite powder is used to refine kerosene; it is used as a contrast agent for the digestive tract in the pharmaceutical industry; it can also be used to make pesticides, leather, fireworks, etc. In addition, barite is also used to extract metal barium, as a getter and binder for televisions and other vacuum tubes. Barium is alloyed with other metals (aluminum, magnesium, lead, calcium) and used in bearing manufacturing.

As long as the selection of the mill is based on the output and its fineness requirements, different types of hosts are selected. The fineness of the finished product of the BARITE GRINDING MILL is between 200 mesh and 325 mesh. The barite raymond mill is a technical update based on the R-type mill. The technical indicators of this product have been greatly improved compared with the R-type mill. It is a new type of high-efficiency and energy-saving mill product. The fineness of the finished product can be adjusted arbitrarily between 22-180μm (80-600 mesh). This product is an updated product of the R-type mill. Among them, the HC1700 large vertical pendulum mill is a large Raymond mill that has been successfully developed early in China. Its output is about 2.5 to 4 times higher than that of similar 5R equipment. It effectively increases the unit output of a single device and reduces the unit. Output and energy consumption are ideal for large-scale milling projects.

Finished product size: 22-180μm

Production capacity: 1-25t/h

ADVANTAGES AND FEATURES

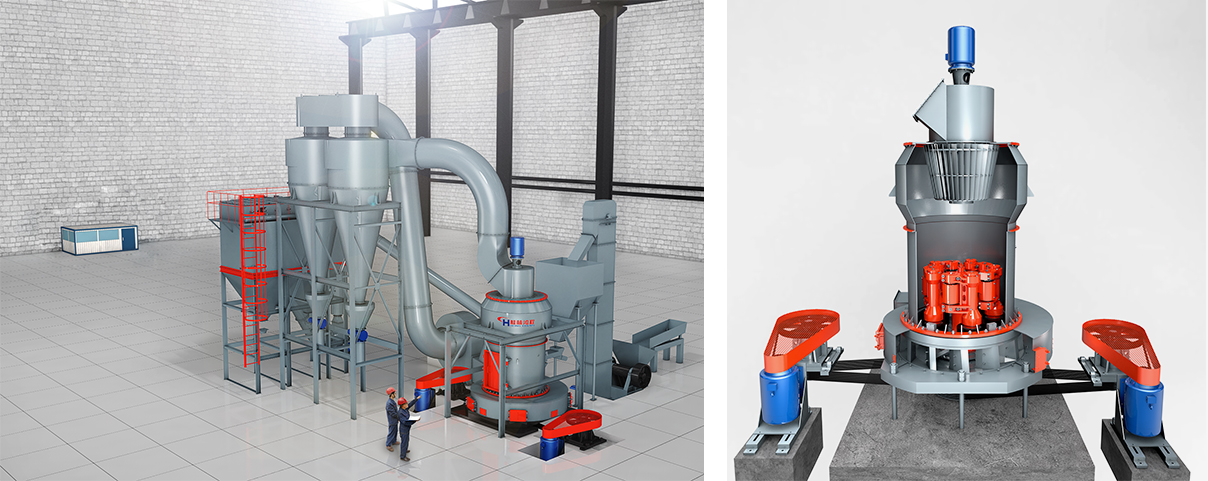

New technology, spider-arm and pendulum grinding system. The machine has very small vibration, low noise, stable mechanical operation and reliable performance.

|

The processing capacity of materials is larger and the efficiency is higher. Under the condition that the total power of the R-type mill is unchanged, the output is increased by more than 40% year-on-year, and the unit power consumption cost is saved by more than 30%. |

|

|

collector, and its dust collection efficiency reaches 99.9%. All the positive pressure parts of the main machine are sealed, and a dust-free processing workshop is basically realized. |

can be filled with grease once in 300-500 hours. In addition, there is no need to remove the grinding roller device to replace the grinding ring, which is more convenient for maintenance. |

MILL STRUCTURE & WORKING PRINCIPLE

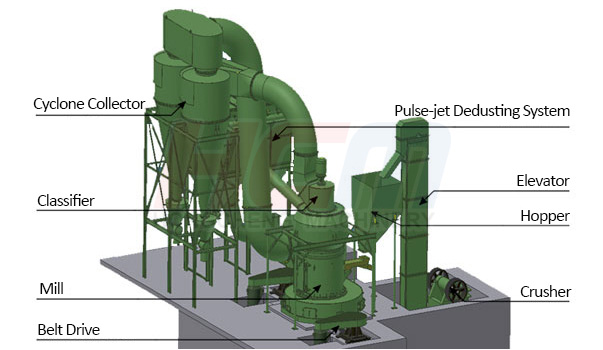

HC barite raymond grinding mill complete equipment consists of base, center shaft support, grinding ring, spider-arm, roller assembly, center shaft, lifter support, lifter support base, housing and other structures.

WORKING PRINCIPLE

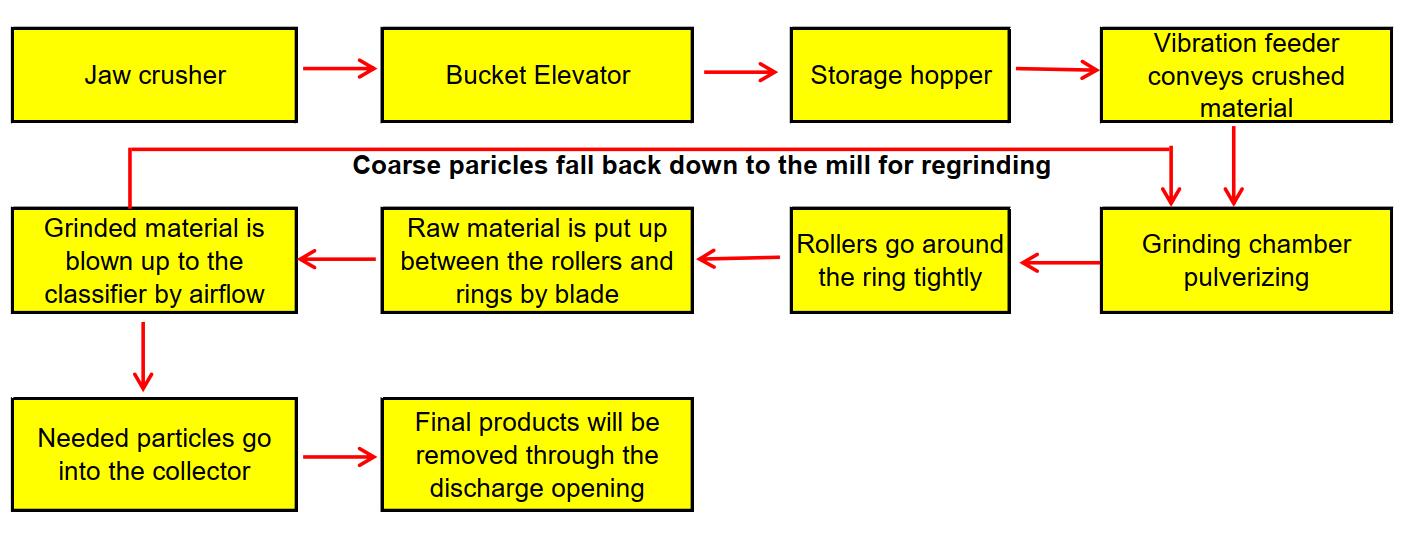

Material is broken by jaw crusher firstly into required size, which are carried by bucket elevator up to storage hopper, again by feeder quantitative into host cavity for grinding, host cavity support in the plum flower rack roller device rotation around the center axis, roller under the action of centrifugal force, horizontal swing outward, so that the roller compaction of ring, roller grinding roller rotation around at the same time.

BARITE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of barite are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of barite are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Number |

Roller Diameter (mm) |

Ring Inner Diameter (mm) |

Ring Number |

Main Motor Power (kw) |

Blower Power (kw) |

Classifier Motor Power (kw) |

| HC1000 | 3 | 320 |

1075 | 1 | 45 |

45 | 11 |

| HC1300 | 4 | 410 |

1270 |

1 | 90 | 90 | 15 |

| HC1500 | 4 | 460 | 1500 | 1 | 132 | 132 | 22 |

| HC1700 | 5 | 510 |

1700 | 1 | 160 |

160 | 22 |

Note:

1. The Models above are equiped with newly designed spider-arm structure.

2. The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

SUCCESSFUL CASES

BARITE PENDULUM GRINDING MILL MACHINE MICRONIZATION PROCESS PROJECT

Processing material: barite

Fineness: 325 mesh D97

Output: 8-10t/h

Equipment configuration: 1 HC1300

OTHER RELATED GRINDING MILL RECOMMENDATIONS

TECHNICAL INNOVATION CALCIUM CARBONATE PENDULUM CALCIUM CARBONATE HCH ULTRAFINE RING ROLLER SUPER FINE TALC ENERGY EFFICIENT NONMETALLIC

GRINDING MILL MODEL HC1700 GRINDING MILL GRINDING MILL MANUFACTURING PRICE

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE