- all

- product

- blog

- all

- product

- blog

Details

SHALE DISINTEGRATOR MACHINE CERAMIC RAW MATERIAL POWDER CENTRIFUGAL GRINDING MILL

Shale is hardened by clay to form tiny particles that are easy to crack and easily split into obvious rock formations. In general, the SiO2 content of shale fluctuates between 45% and 80%, and the MgO content fluctuates between 0.1% and 5%.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

Shale is hardened by clay to form tiny particles that are easy to crack and easily split into obvious rock formations. The hardness of shale is generally 1.5 to 3 with a Platts hardness coefficient. The structure is relatively dense, and its Platts hardness coefficient can reach 4 to 5, and some hard shale has a higher hardness. In general, the SiO2 content of shale fluctuates between 45% and 80%, and the MgO content fluctuates between 0.1% and 5%. Guilin Hongcheng disintegrator machine is used to produce ceramic raw material powder mixture.

SHALE DISINTEGRATOR MACHINE CERAMIC RAW MATERIAL POWDER CENTRIFUGAL GRINDING MILL is a large-scale product based on the company's HC1700 vertical pendulum mill. This series of mills is a large-scale environmental protection mill independently developed by Guilin Hongcheng Mining Equipment Manufacturing Co., Ltd., covering 5 invention patents. The fineness range of its products is between 38-180μm (80-400 mesh), which can meet the domestic industrial policy and the expanding demand for industrialized scale production, make up for the blank of my country's large-scale pendulum mill, and expand the pendulum mill. The application field of the powder machine has greatly improved the efficiency of the user's equipment in terms of production capacity and unit energy consumption, and its technical level will be at the domestic advanced level.

This product is suitable for grinding activated carbon and other non-flammable and explosive materials with Mohs hardness below 7 and humidity within 6%.

Finished product size: 38-180μm

Production capacity: 3-90t/h

ADVANTAGES AND FEATURES

New type of spide-arm featured in compact structure. It can be maintained New type of spide-arm featured in compact structure. It can be maintainedwithout disassembly, which save the maintenance time. |

Adopt maintenance-free oil seal technology, screw seal and skeleton oil sealmulti-layer barrier, limited to prevent dust from entering, can achieve add lubri-cating oil per 500~800 hours, reduce the maintenance cost. |

|

Unique high chromium alloy material technology, the use time is nearly 3 times of the industry standard. |

Forced turbine classification technology. The particle size of finished products can be adjusted infinitely between 80~400 mesh. |

|

Off-line pulse dust collection system, dust collection rate up to 99.9%. |

MILL STRUCTURE & WORKING PRINCIPLE

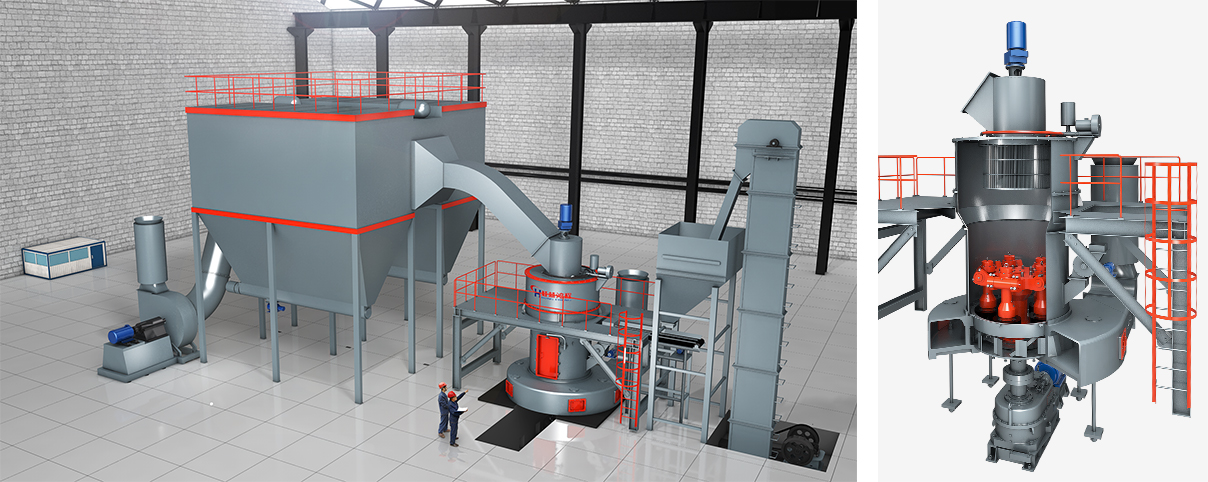

HC shale centrifugal grinding mill consists of mill system, classifying system, screening, collecting system and other components. The mill system adopts the structure of integral casting base, which can be used as shock absorbing foundation. The classifying system adopts mandatory turbine classifier structure and the collecting system adopts pulse collection.

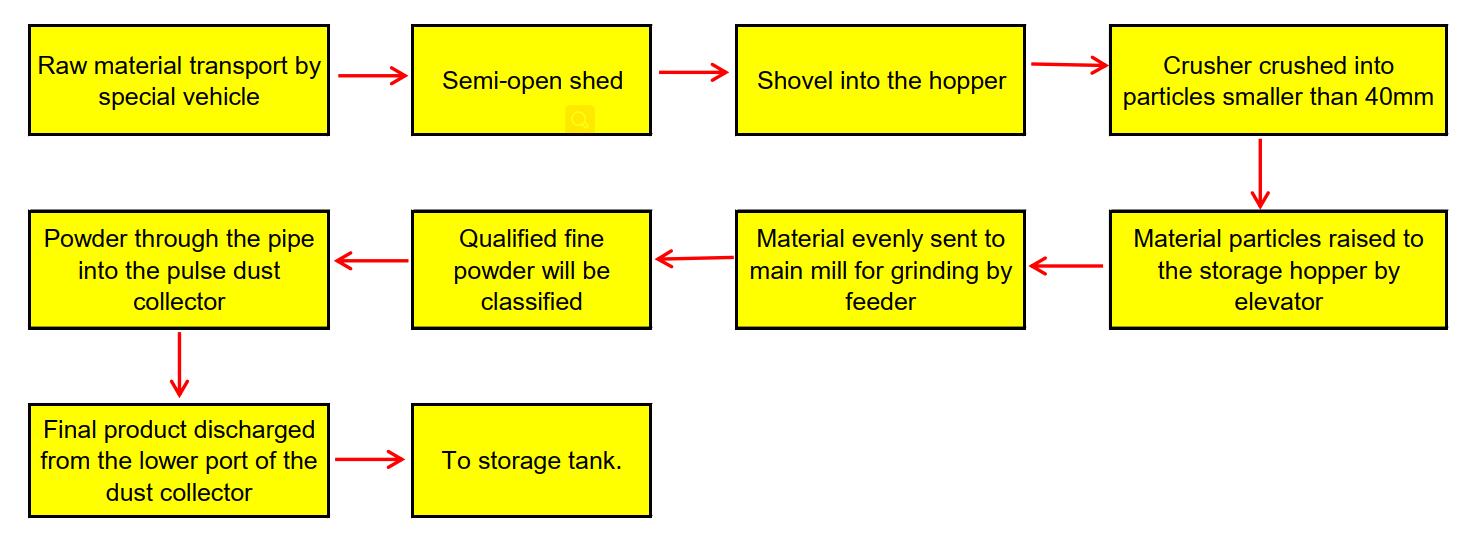

STONE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of shales are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of shales are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Nomber |

Ring Diameter (mm) |

Max. Feeding (mm) |

Fineness (mm) |

Capacity (t/h) |

Total Power (kw) |

| HC1900 | 5 | 1900 | 40 | 0.038-0.18 | 10-35 | 555 |

| HC2000 | 5 | 2000 | 40 | 0.038-0.18 | 15-45 | 635-705 |

Note:

1. The Models above are equiped with newly designed spider-arm structure.

2. The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

SUCCESSFUL CASES

A PORCELAIN FACTORY GRINDING CASE OF 200 MESH 12T SHALE MIXTURE

Equipment model and number: 1 HC1900

Processing materials: shale

Finished product fineness: 200 mesh

Equipment output: 12t/h

OTHER RELATED GRINDING MILL RECOMMENDATIONS

LARGE CAPACITY VERTICAL RAYMOND GRINDING LIMESTONE HONGCHENG LOW PRICE SLAKED LIME POWDER PRODUCTION STONE POWDER GRINDER EQUIPMENT RAYMOND MILL PRICE

POWDER PROCESSED PLANT LINE USES

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE