- all

- product

- blog

- all

- product

- blog

Details

PULVERIZED PYROPHYLLITE PENDULUM ROLLER MILL ORE PROCESSING PLANT

As a pyrophyllite powder mill manufacturer, Guilin Hongcheng has a variety of models of pyrophyllite powder production line equipment, which has created considerable benefits for many pyrophyllite manufacturers.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

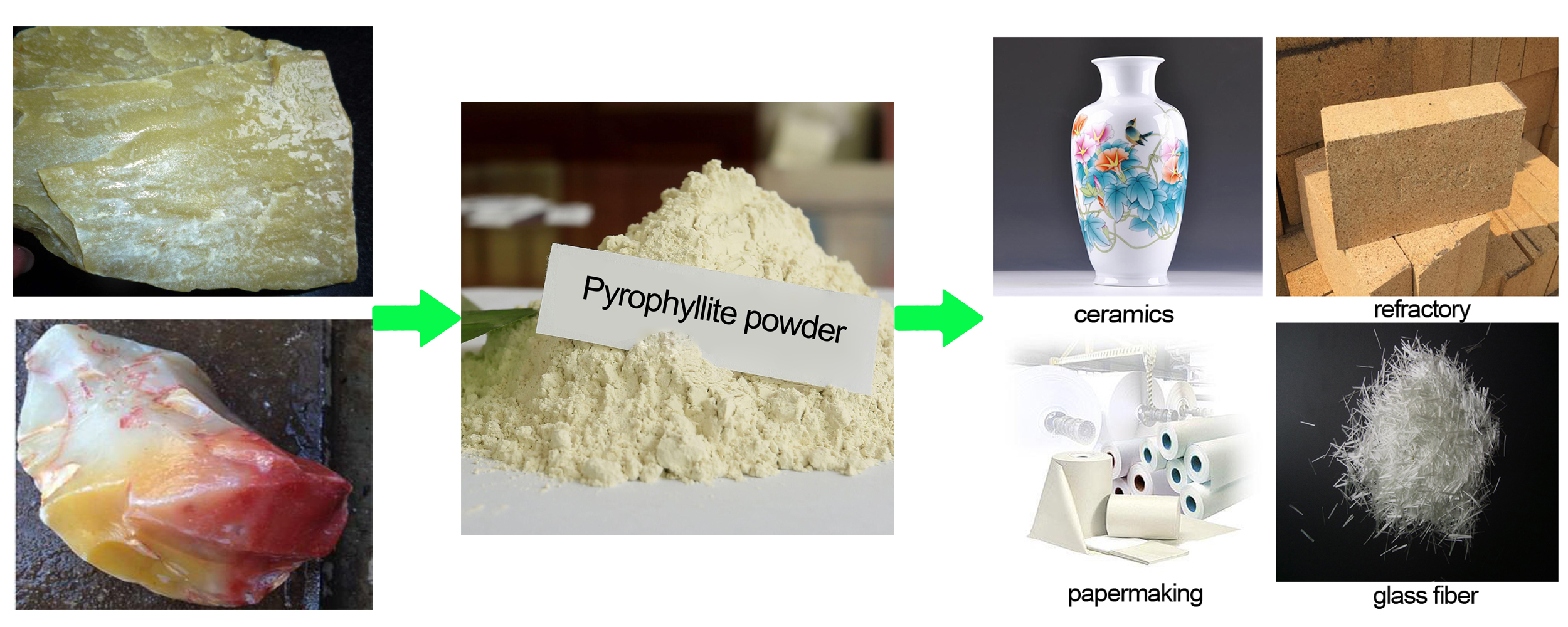

INTRODUCTION OF PRODUCT

Pyrophyllite is a kind of clay minerals, with fine texture and low hardness (1-2). It is suitable for ceramics, refractory materials, glass fibers, carving stones, etc. It can be widely used in ceramics, metallurgy, building materials, chemical industry, light industry and other industrial sectors. The processing flow of pyrophyllite is determined according to the requirements of the product. For example, the pyrophyllite used in the production of refractory materials and refractory bricks does not require high whiteness and the product size is not required to be very fine. It is used for ceramics, papermaking, The fineness of pyrophyllite such as pesticide carrier is often required to be below 200 mesh, and the whiteness is above 85%. As a pyrophyllite powder mill manufacturer, Guilin Hongcheng has a variety of models of pyrophyllite powder production line equipment, which has created considerable benefits for many pyrophyllite manufacturers.

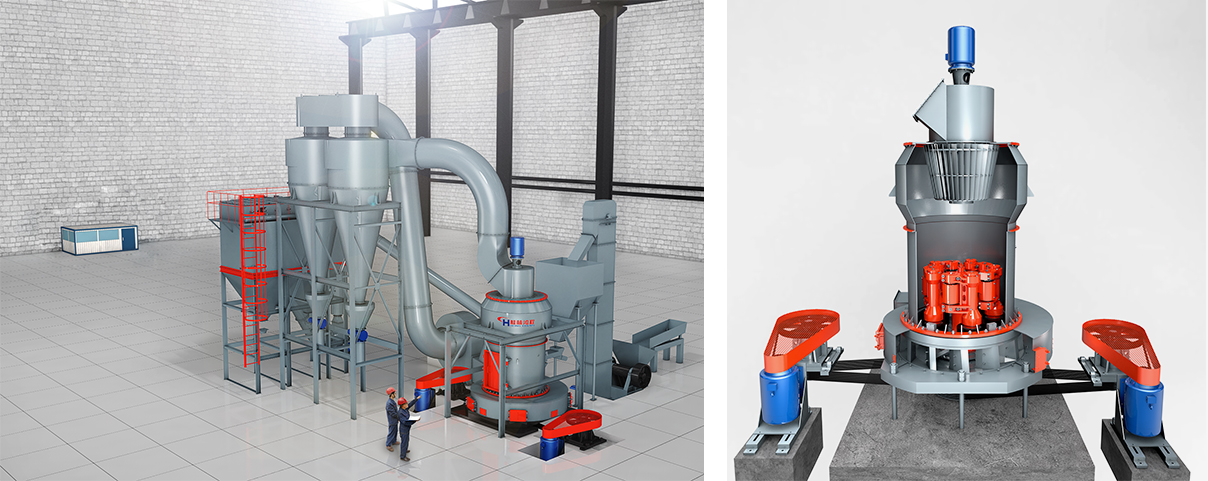

As long as the selection of the mill is based on the output and its fineness requirements, different types of hosts are selected. The fineness of the finished product of the HC PULVERIZED PYROPHYLLITE PENDULUM ROLLER MILL ORE PROCESSING PLANT is between 200 mesh and 325 mesh. The HC pendulum roller mill is a technical update based on the R-type mill. The technical indicators of this product have been greatly improved compared with the R-type mill. It is a new type of high-efficiency and energy-saving mill product. The fineness of the finished product can be adjusted arbitrarily between 22-180μm (80-600 mesh). This product is an updated product of the R-type mill. Among them, the HC1700 large pulverized pyrophyllite mill is a large Raymond mill successfully developed early in China. The output is about 2.5 to 4 times higher than that of similar 5R equipment, which effectively increases the unit output of a single device and reduces the unit. Output and energy consumption are ideal for large-scale milling projects.

Finished product size: 22-180μm

Production capacity: 1-25t/h

ADVANTAGES AND FEATURES

New technology, spider-arm and pendulum grinding system. The machine has very small vibration, low noise, stable mechanical operation and reliable performance.

|

The processing capacity of materials is larger and the efficiency is higher. Under the condition that the total power of the R-type mill is unchanged, the output is increased by more than 40% year-on-year, and the unit power consumption cost is saved by more than 30%. |

|

|

collector, and its dust collection efficiency reaches 99.9%. All the positive pressure parts of the main machine are sealed, and a dust-free processing workshop is basically realized. |

can be filled with grease once in 300-500 hours. In addition, there is no need to remove the grinding roller device to replace the grinding ring, which is more convenient for maintenance. |

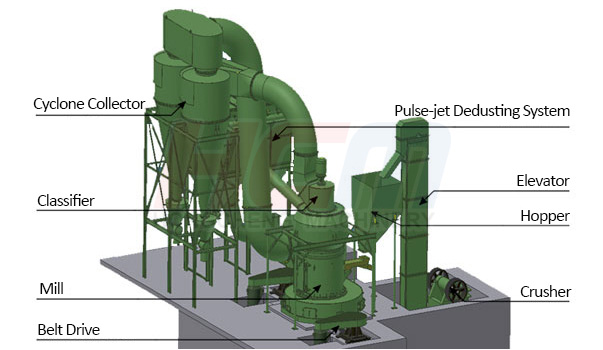

MILL STRUCTURE & WORKING PRINCIPLE

HC1700 ore processing plant consists of base, center shaft support, grinding ring, spider-arm, roller assembly, center shaft, lifter support, lifter support base, housing and other structures.

WORKING PRINCIPLE

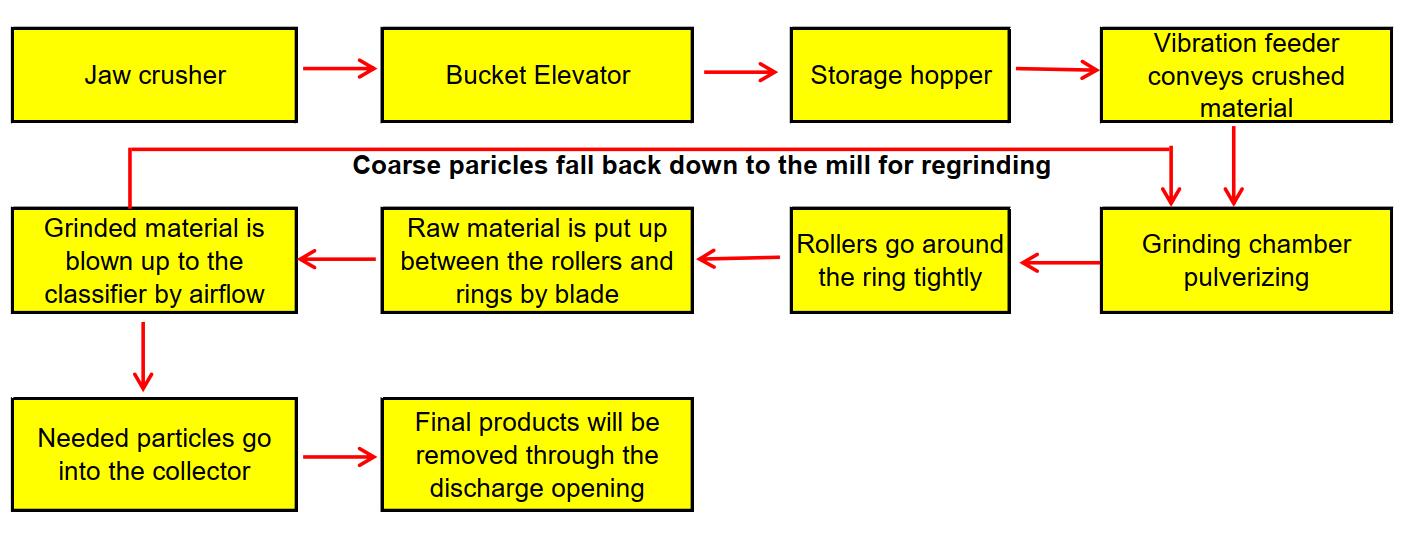

Material is broken by jaw crusher firstly into required size, which are carried by bucket elevator up to storage hopper, again by feeder quantitative into host cavity for grinding, host cavity support in the plum flower rack roller device rotation around the center axis, roller under the action of centrifugal force, horizontal swing outward, so that the roller compaction of ring, roller grinding roller rotation around at the same time.

PYROPHYLLITE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of pyrophyllite are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of pyrophyllite are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Number |

Roller Diameter (mm) |

Ring Inner Diameter (mm) |

Ring Number |

Main Motor Power (kw) |

Blower Power (kw) |

Classifier Motor Power (kw) |

| HC1000 | 3 | 320 |

1075 | 1 | 45 |

45 | 11 |

| HC1300 | 4 | 410 |

1270 |

1 | 90 | 90 | 15 |

| HC1500 | 4 | 460 | 1500 | 1 | 132 | 132 | 22 |

| HC1700 | 5 | 510 |

1700 | 1 | 160 |

160 | 22 |

Note:

1. The Models above are equiped with newly designed spider-arm structure.

2. The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

SUCCESSFUL CASES

PYROPHYLLITE POWDER PRODUCTION LINE WITH AN ANNUAL OUTPUT OF 60,000 TONS

The model and number of this equipment: 1 HC1700

Processing material: pyrophyllite

Fineness of finished product: 200 mesh D97

Equipment output: 6-8t/h

OTHER RELATED GRINDING MILL RECOMMENDATIONS

WORKING PRINCIPLE OF PENDULUM GRINDING MACHINE- CLAY RAYMOND MILL INDUSTRIAL DASEMENT BENTONITE FOR SUPER FINE TALC ENERGY EFFICIENT NONMETALLIC

RAYMOND MILL FOR SALE RECYCLED MACHINE OIL SUPPLIERS GRINDING MILL MANUFACTURING PRICE

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE