- all

- product

- blog

- all

- product

- blog

What kind of heavy calcium carbonate is used in the plastics industry?

- 2020-03-07 08:53

- HCM

What kind of heavy calcium carbonate is used in the plastics industry?

Heavy calcium carbonate is the preferred filler in the plastics industry. It is widely used in the plastics industry such as plastic film, profiles, pipes, woven and wire drawing and artificial leather. Its role in plastic processing includes:

Increase volume and weight and reduce costs;

Improve processing and dispersion performance;

Improve dimensional stability, rigidity and toughness;

Improve heat resistance, anti-aging performance and UV resistance;

And it can replace the expensive white pigment, play the role of increasing whiteness and improve the superficial gloss and flatness of the product.

So, what are the requirements for index of heavy calcium carbonate in the plastics industry? Why are these indicators required?

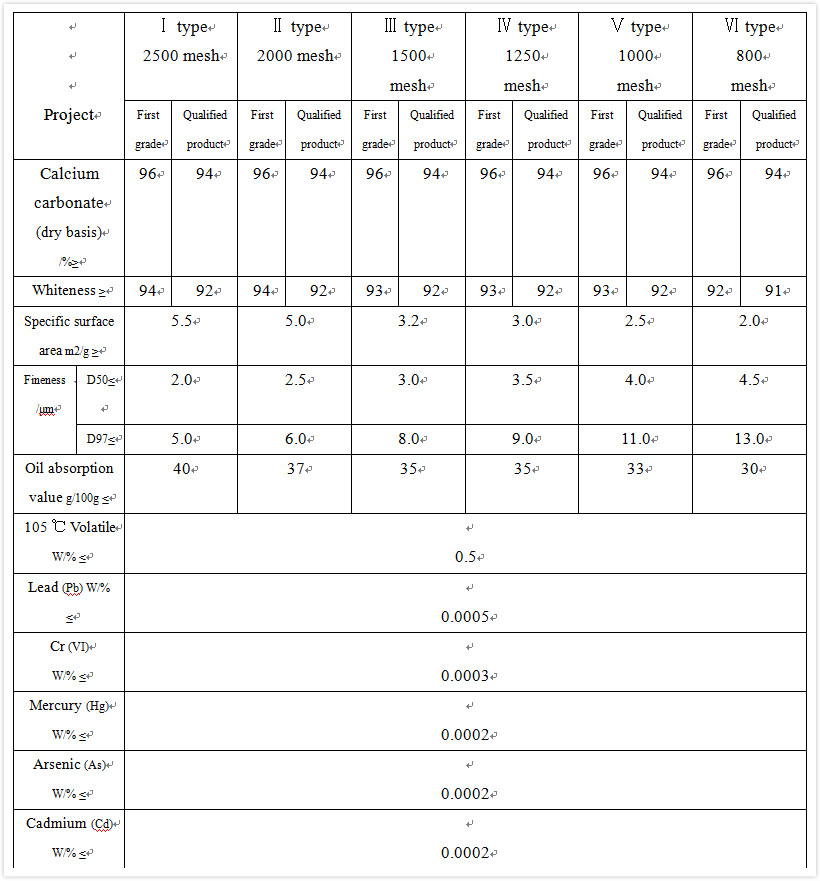

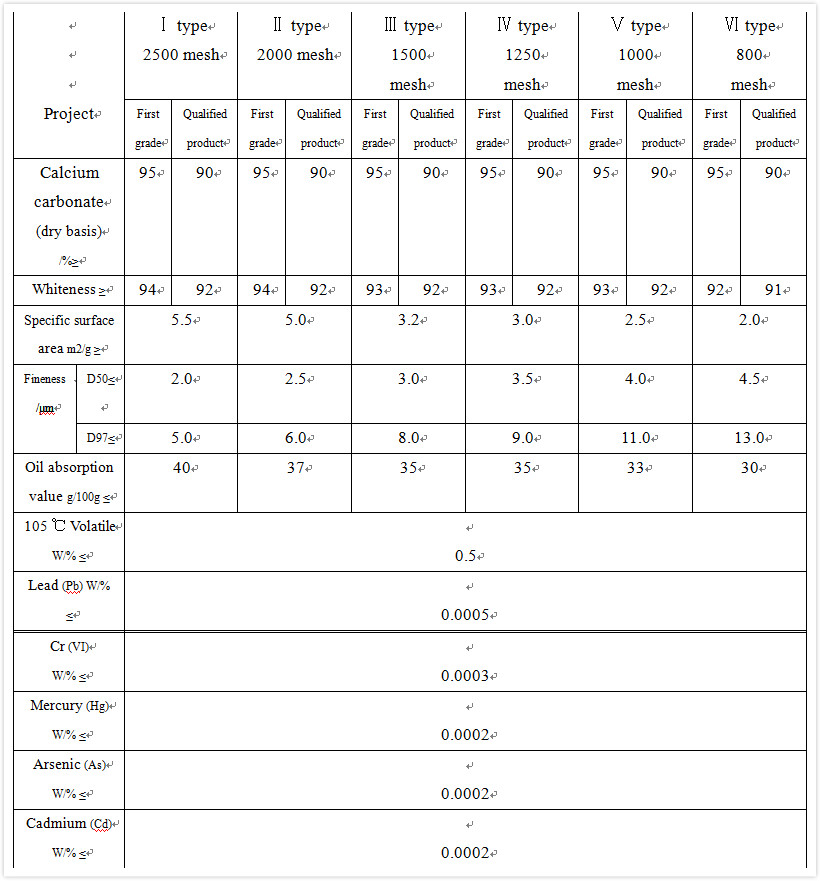

Index requirements of heavy calcium carbonate used in general plastics industry

Index requirements of heavy calcium carbonate used in general plastics industry

(Heavy calcium carbonate has been superficially modified)

1.Whiteness

The whiteness mainly affects the color and appearance of the plastic-filled products, and does not affect the mechanical properties and processing properties of the materials. The higher the whiteness is, the effect on the coloration of the filled plastic is smaller. And under the same condition, the higher the whiteness is, the more competitive it is.

Principally, in the application of plastics, it is better to use heavy calcium carbonate with high whiteness. The whiteness of heavy calcium carbonate applied in ordinary plastics should be bigger than 92%, and the whiteness of heavy calcium carbonate for high-grade master batch of filled plastic should reach 95%.

2. Impurity content

The content of impurities not only affects the color and appearance of the filled plastic products, but also affects the mechanical properties and processing properties of the materials.

In principle, requires that the impurity content of heavy calcium carbonate used in the plastics industry should be as low as possible. While, it is better to use heavy calcium carbonate with higher content. The main impurities that affect plastics are Fe2O3, MgO, SiO2 and so on.

If the content of Fe2O3 is high, the color of heavy calcium carbonate will be affected, and the Fe2O3 is easy to become yellow. Especially when its surface is modified, it will be combined with acidic substances such as stearic acid. Besides, it will easily become yellow under high temperature, and iron ions can accelerate the aging of plastic.

Heavy calcium powder with high content of MgO will produce dust. If the heavy calcium carbonate containing dolomite is added to polyethylene plastics and polypropylene plastics, fillers will be gray, because the main components of dolomite are the calcium carbonate and the magnesium carbonate.

Polyvinyl chloride will produce light cross-linking or thermal degradation and its thermal stability will reduce because of the presence of SiO2. Furthermore, the high content of silicon in heavy calcium carbonate will lead to increased hardness of the particles, which has a greater impact on machinery wear during plastic processing. For example, the slitting blade wears easily when filler master batch made of heavy calcium carbonate with high content of silicon is used for the production of polypropylene flat yarn.

3. Particle size and its distribution

Particle size and its distribution are important indicators for the measuring of the grade of heavy calcium carbonate product. They mainly affect the mechanical properties of materials. In theory, if finer particle size of the heavy calcium carbonate is filled into plastics, the stronger the strength of the product will be. However, it is different in the practical application. The finer the particle size of heavy calcium carbonate is, the larger the specific surface area is and the larger the surface energy is. The particles can agglomerate easily and they are added into the resin in form of multiple aggregation. Because its dispersion is uneven, it is difficult to form a stable interface, which degrades the performance of the product.

Therefore, fineness of the heavy calcium carbonate applied in plastics should be appropriate. It isn’t the case that the finer the heavy calcium carbonate is better. Currently, the commonly used heavy calcium carbonate is generally between 400-1250 mesh. And the powder with a fineness of 400-800 mesh accounts for about 65% of the market share, 800- 1250 mesh, about 30%, and 1250 mesh about 5-10%.

The index of particle size and its distribution is required to be D97 and D100. It is required that the fineness of the product should be 2μm, average particle size should be D50 and specific surface area of the product. These indicators indirectly reflect the dispersion of heavy calcium powder and the level of oil absorption.

For filled plastics, under the same filling proportion, the finer the particle size is, the better the mechanical properties of the filled plastic is, but the premise is that the particles of heavy calcium carbonate need to be uniformly dispersed in the plastic matrix. There are some differences in the distribution of heavy calcium carbonate applied in plastics. For example, it is required that for the injection-molding products, its fillers should have good fluidity. And low content of fine powders and coarse heavy calcium carbonate with high content contribute to the processing fluidity of filler materials. But if the product is D100, it is better to use larger average particle size.

4. Particle morphology and crystal form

The particle morphology of heavy calcium carbonate has a great influence on the filling and modification of plastics. For example, fibrous and flake-like heavy calcium carbonate are beneficial to the mechanical strength of polyvinyl chloride composites, but they are not good for the processing of molding. While spherical fillers can improve the molding and processing performance of materials, but the mechanical strength of the material will be reduced.

The influence of crystal structure has begun to attract attention in the industry. Generally speaking, the heavy calcium powder produced by natural calcite in form of fine grain, semi-automatic crystal, granular or lump structures is favored by the plastics industry.

5. Oil absorption value

In principle, as to the heavy calcium carbonate applied in plastics, the lower the oil absorption value is better, because heavy calcium carbonate with high oil absorption value will absorb the plasticizer into the filler, so the function of plasticizing resin. In order to make the material reach a certain degree of flexibility, the amount of plasticizer must be increased. As a result, cost is increased.

▼ Requirements for the oil absorption value of heavy calcium from a domestic plastics enterprise

Heavy calcium (mesh) |

400 |

600 |

800 |

1000 |

1250 |

oil absorption value (g/100g) |

21 |

23 |

25 |

28 |

30 |

6. Moisture and low-molecular substances

Moisture and low-molecular substances are big taboos for any plastic products, because moisture and low-molecular substances will cause defects and wrinkles on the surface of the product. In severe cases, the product will be in form of honeycomb. And the transportation of materials will stop, which not only affects the mechanical properties of the product, also affects the appearance of the product.

As to the heavy calcium carbonate product, its whiteness, content of impurity and the crystal structure are mainly affected by the grade of raw ore. The particle morphology, particle size and distribution are closely related to raw materials, processing equipment, process and technology as well as the control level.

Therefore, the enterprise of heavy calcium carbonate, at first, should select raw ore according to the application requirements of the plastics industry, and then the processing equipment and processes should meet the requirements of refined processing of heavy calcium products. Only under such conditions can the heavy calcium carbonate products realize its values in each adaptive plastics industry and increase added value.

If you are interested in the vertical roller mill, Please contact us for details:

Tel:+86-0773-3568321

E-mail: hcm@hcmilling.com

(Translation from www.cnpowdertech)

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07