- all

- product

- blog

- all

- product

- blog

limestone

- 2021-03-24 10:42

- HCM

The largest amount of limestone powder currently used is limestone powder for desulfurization in power plants.

What is limestone

The main component of limestone is calcium carbonate (CaCO3). Lime and limestone are widely used in construction materials and industrial raw materials. Limestone is directly processed into stone and burned into quicklime. Quicklime becomes hydrated lime by absorbing moisture or adding water. The main component is Ca(OH)2. The slaked lime is prepared into lime slurry, lime paste, etc., which is used as coating material and brick adhesive. Calcium carbonate is the main component of limestone, and limestone is the main raw material for glass production. Calcium carbonate can be directly processed into stone and burned into quicklime. Lime includes quicklime and slaked lime. The main component of quicklime is CaO, which is generally lumpy, pure white, and light gray or light yellow when it contains impurities. Quicklime becomes slaked lime by absorbing moisture or adding water. Slaked lime is also called slaked lime, and its main component is Ca(OH)2. The slaked lime is formulated into lime slurry, lime paste, lime mortar, etc., which are used as coating materials and brick adhesives. Cement is made by mixing limestone and clay and calcining at high temperature.

Uses of limestone

Limestone is ground by a limestone mill to prepare limestone powder. Limestone powder has a wide range of uses according to different specifications:

1. Single fan:

It is used to produce anhydrous calcium chloride and is an auxiliary raw material for the production of sodium dichromate. The main raw material for glass and cement production. In addition, it is also used in building materials and poultry feed.

2. Shuangfei fans:

It is used to produce raw materials such as anhydrous calcium chloride and glass, white fillers for rubber and paint, and building materials.

3. Three flying fans:

Used as filler for plastics, paint putty, paint, plywood and paint.

4. Four flying fans:

Used as filler for wire insulation layer, rubber molded products and filler for asphalt linoleum

5. Power plant desulfurization:

Used as desulfurization absorbent for power plant flue gas desulfurization.

Limestone pulverizing process

The largest amount of limestone powder currently used is limestone powder for desulfurization in power plants.

Limestone raw material composition analysis

| CaO | MgO | Al2O3 | Fe2O3 | SiO2 | SO3 | Burning amount | Loss |

| 52.87 | 2.19 | 0.98 | 1.08 | 1.87 | 1.18 | 39.17 | 0.66 |

Remarks: Limestone varies greatly from place to place, especially the high content of SiO2 and Al2O3 is difficult to grind.

Limestone pulverizing host selection scheme

| Product specifications (mesh) | 200 mesh,D95 | 250 mesh,D90 | 325 mesh,D90 |

| Selection scheme | Vertical mill / Super large Raymond mill | ||

1. System power consumption per ton of product: 18~25kWh/t varies according to raw material and product requirements;

2. Select the host according to the output and fineness requirements;

3. Main uses: electric power desulfurization, blast furnace smelting solvent, etc.

1. Crush materials

Large pieces of limestone are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

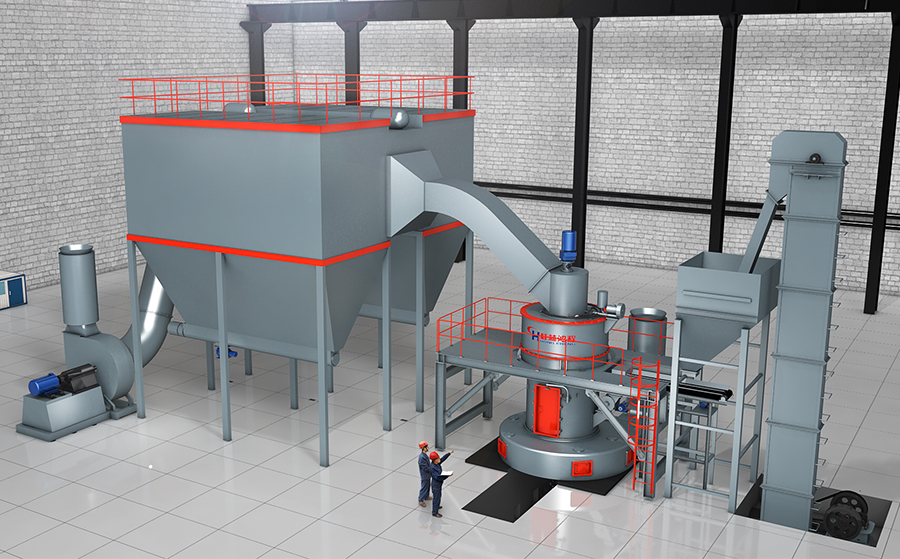

2. Milling

The crushed small pieces of limestone are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collect finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

| HC series large pendulum mill | ||||

|

* For coarse powder below 600 mesh. * The equipment investment cost is low. * Consumption is low |

* Large-scale equipment and high output can meet large-scale production. * High stability. * Disadvantages: high equipment investment costs. |

* The production of ultra-fine powder has low energy consumption and low equipment investment cost. * The market prospects for large-scale ring roller mills are good. * Disadvantages: low output. |

Classic case of limestone milling

Desulfurization project of a power plant with an annual output of 150,000 tons of a calcium industry group

Equipment model and number: 2 HC1700

Processing material: limestone

Finished product fineness: 325 mesh D96

Equipment output: 10t/h

The Calcium Industry Group is a large-scale metallurgical ash production enterprise in my country's township enterprises, a designated supplier of metallurgical raw materials for large and medium-sized enterprises in China, and a leading calcium powder enterprise with a production capacity of 1 million tons of limestone. Guilin Hongcheng began to participate in the transformation of the power plant's desulfurization project in 2010. The customer has successively purchased two Guilin Hongcheng HC1700 vertical pendulum mill equipment and two 4R Raymond mill equipment. So far, the mill equipment has been operating stably. Bring high economic benefits to the owner.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07