- all

- product

- blog

- all

- product

- blog

barite

- 2021-03-27 16:22

- HCM

What is barite

Barite is a non-metallic mineral product with barium sulfate (BaSO4) as the main component. Pure barite is white and shiny. Due to the influence of impurities and mixed substances, it is often gray, light red, light yellow, etc., and the crystallization situation is similar. Good barite can also appear as transparent crystals. my country’s barite resources are abundant, distributed in 26 provinces, municipalities and autonomous regions, mainly in the south. Guizhou Province accounts for one-third of the country’s total reserves, Hunan and Guangxi rank second and third in the country, respectively. In addition to large reserves, but also high grade, barite deposits in my country can be divided into four types, namely sedimentary deposits, volcanic deposits, hydrothermal deposits and residual slope deposits. Barite is chemically stable, insoluble in water and hydrochloric acid, non-magnetic and toxic, and can absorb X-rays and gamma rays.

Uses of barite

Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

① Drilling mud weighting agent: In some oil and gas well drilling, adding barite powder to the mud is an effective measure to increase the proportion of mud, and it is the most commonly used measure in drilling operations that can effectively avoid frequent blowout accidents.

② Lithopone pigment: heating barium sulfate, using a reducing agent to reduce to barium sulfide (BaS), and then reacting with zinc sulfate (ZnSO4) to obtain a mixture of barium sulfate and zinc sulfide (BaSO4 accounts for 70%, ZnS accounts for 30%) %) is the lithopone pigment. It can be used as a raw material for paints and painting pigments. It is a commonly used high-quality white pigment.

③ Various barium compounds: Barium oxide, barium carbonate, barium chloride, barium nitrate, precipitated barium sulfate, barium hydroxide and other chemical raw materials can be produced by using barite as raw material.

④ Used in industrial fillers: In the paint industry, barite powder fillers can increase the thickness, strength and durability of the paint film. In the fields of paper, rubber, and plastics, barite can improve the hardness, abrasion resistance and aging resistance of rubber and plastics; Lithopone pigment is also used to make white paint, which is more used indoors than lead white and magnesium white The advantages.

⑤ Mineralizer for cement industry: The use of barite and fluorite composite mineralizer in cement production has obvious effects on promoting the formation of C3S and activating C3S, and the quality of clinker has been improved.

⑥ Anti-ray cement, mortar and concrete: use barite to absorb X-rays, and use barite to make barium cement, barite mortar and barite concrete, which can be used to replace metal lead plates to shield nuclear reactors and build scientific research , X-ray-proof buildings in hospitals.

⑦ Road construction: A mixture of rubber and asphalt containing about 10% barite has been successfully used in parking lots and is a durable paving material.

⑧ Others: barite and oil are blended and coated on cloth to make tarpaulin; barite powder is used to refine kerosene; it is used as a contrast agent for the digestive tract in the pharmaceutical industry; it can also be used to make pesticides, leather, and fireworks. In addition, barite is also used to extract metal barium, as a getter and binder for televisions and other vacuum tubes. Barium is alloyed with other metals (aluminum, magnesium, lead, calcium) and used in bearing manufacturing.

Barite powder production process

Analysis of raw material composition of barite

| CaO | SO3 |

| 65.7% | 34.3% |

Remarks: Sr, Pb and Ca are similarly substituted in the composition.

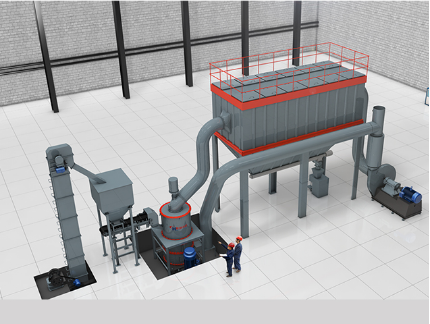

Selection scheme of barite powder grinding mill

| Product specifications (mesh) | 200 mesh | 325 mesh | 600-2500 mesh |

| Selection scheme | Raymond mil |

HLMX superfine vertical grinding mill | |

| Vertical grinding mill | HCH ring roller ultrafine grinding mill |

||

| Jet mill | |||

Remarks: Choose different types of hosts according to the output and fineness requirements.

1. Crush raw materials

The barite bulk material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of barite are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collect finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

| HLM series vertical mill | ||

|

Large-scale equipment and high output can meet large-scale production. The vertical mill has higher stability. Disadvantages, high equipment investment costs. |

A new choice for processing ultra-fine barite powder: high output, realizing large-scale production of ultra-fine barite processing. |

|

Process 600-2500 ultra-fine powder, with low equipment investment cost and low energy consumption. |

Low investment cost, high output, low energy consumption, stable equipment, low noise; for processing fine powder above 400 mesh, or as a primary crushing equipment for jet mills, pendulum mills are an ideal choice for high cost performance. |

Classic case of barite powder milling

Processing material: barite

Fineness: 325 mesh D97

Output: 8-10t/h

Equipment configuration: 1 HC1300

Producing the same specifications of powder, the output of HC1300 is almost 2 tons higher than the traditional 5R machine, and the energy consumption is low. The entire system is fully automated, and workers only need to operate in the central control room, which is simple to operate and save labor costs. With lower operating costs, the products will become competitive. Moreover, all the design, installation guidance, and commissioning of the entire project are free of charge, and we are very satisfied.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07