- all

- product

- blog

- all

- product

- blog

bentonite

- 2021-04-23 15:00

- HCM

What is bentonite

Bentonite is also known as bentonite, bentonite, sweet clay, bentonite, pottery clay, white clay, and is commonly known as Guanyin clay. It is a clay mineral with montmorillonite as the main component. Its chemical composition is quite stable and is known as the "universal stone". Montmorillonite is composed of two layers of co-topped silicon-oxygen tetrahedral sheets and a layer of co-edge-connected aluminum (magnesium) oxygen (hydrogen oxygen) octahedral sheets, forming a 2:1 type silicate mineral containing crystal water. It is one of the minerals with strong crystal structure variation in the clay mineral family. Montmorillonite is a mineral belonging to the Montmorillonite group. A total of 11 minerals in the Montmorillonite group are found. They are bentonite clay, beide clay, lithium bentonite, montmorillonite, sodium bentonite, bentonite, and zinc. Bentonite, St. bentonite, hectorite, chromium montmorillonite and copper montmorillonite, etc., but from the internal structure can be divided into montmorillonite subfamily (two octahedron) and bentonite subfamily (38 Face body). Montmorillonite is one of the typical layered silicate minerals, but it is different from other layered silicate minerals in that the gaps between the layers are particularly large, so that an indefinite amount of water can be contained in the layers. Molecules and exchangeable cations. The test results of the slow scanning of the diffractometer show that the particle size of montmorillonite is close to the nanometer level, and it is a natural nanomaterial.

Uses of bentonite

Bentonite is ground and processed by a bentonite mill to prepare bentonite powder. Bentonite powder is widely used according to different types and specifications:

Refined Lithium Bentonite

Mainly used in various casting coatings and various ceramic color glaze coatings, as a suspending agent and thixotropic agent for the base material. Used in daily chemicals such as latex paint, used as a thixotropic agent, latex stabilizer and thickener for suspoemulsions and pastes, and as a slurry on fabrics.

Refined sodium bentonite

① In the mechanical casting industry, it can be used as foundry sand and binder, which can overcome the phenomenon of "sand inclusion" and "skinning" of castings, reduce the rejection rate of castings, and ensure the accuracy and smoothness of castings.

② In the paper industry, it is used as a filler for paper to enhance the brightness of the paper.

③ Use the strong bonding properties of this product to make white latex, floor glue, paste, etc.

④ Because of its stable suspension and thickening properties, it can effectively lift the dispersed powder and can be used as a thickening and anti-settling auxiliary for water-based coatings.

⑤ At the same time, it can use its excellent dispersibility and expansibility, high slurry rate, low water loss, colloid performance and shear thinning ability, and it can be used as sodium soil for drilling mud.

Bentonite for ceramics

The addition of this product in the production of ceramic technology increases the plasticity and strength of the embryo body or glaze, greatly increases the lubricating effect, and is beneficial to ball milling. In addition, the suspension and stability are greatly enhanced, the porcelain is fine and the color tone is soft. The glaze machine is smooth , Good light transmittance, collision resistance, and certain mechanical strength.

High-efficiency activated clay

1. Animal and vegetable oil refining, used for decolorization and purification, to remove harmful pigments, phospholipids, saponin, cotton acid, etc. in the oil, making it a high-end edible oil.

2. In the petroleum industry, it is used in the refining, decolorization and purification of petroleum, grease, paraffin, wax oil, kerosene and other minerals, as well as petroleum cracking.

In the food industry, it is used as a clarifier for wine and sugar juice, stabilization of beer, saccharification, purification of sugar juice, etc.

3. In the chemical industry, it is used as a catalyst, filler, desiccant, adsorbent, and flocculant for wastewater treatment.

4. In national defense, medical and health, it can be made into anti-chemical drug and antidote. With the development of society and science, the application of activated clay has become more and more extensive.

Calcium bentonite

Mainly used as a binder in foundry sand and asbestos insulation materials; radioactive waste absorbent;

Used as a carrier or diluent or pesticide in pesticides; drilling mud flushing fluid.

Bentonite powder making process

Analysis results of chemical composition of bentonite ore and purified soil (%)

|

Sample name |

SiO2 | AL2O3 | Fe2O3 | FeO | TiO3 | K3O | Na2O | CaO | MgO3 | LOI |

|

Xinjiang Sodium Soil |

67.75 | 15.55 | 4.25 | <0.01 | 0.58 | 1.65 | 2.89 | 0.35 | 2.59 | 5.28 |

| Jilin Sodium Soil | 67.21 | 16.87 | 2.88 | 0.88 | 0.20 | 1.46 | 2.99 | 0.88 | 2.32 | 5.45 |

|

Anji calcium soil |

72.31 | 15.07 | 1.62 | <0.01 | 0.12 | 0.87 | 0.46 | 1.39 | 2.06 | 5.96 |

| Sian calcium soil | 72.85 | 72.85 | 1.45 | 0.01 | 0.18 | 1.21 | 0.45 | 2.06 | 2.23 | 5.91 |

|

Changshan calcium soil |

65.80 | 17.73 | 1.34 | - | 0.25 | 0.30 | 0.11 | 1.89 | 4.40 | 7.56 |

| Xinjiang purified soil | 56.70 | 21.36 | 6.01 | - | 0.44 | 0.69 | 3.60 | 0.75 | 3.63 | 7.58 |

|

Jilin purified soil |

60.21 | 22.68 | 4.09- |

- | 0.16 | 0.37 | 2.67 | 0.89 | 2.97 |

6.83 |

|

Anji purified soil |

58.91 | 20.18 | 1.85 | - | 0.06 | 0.79 | 3.80 | 2.56 | 3.82 | 8.77 |

| Sian purified soil | 56.49 | 22.25 | 1.98 | - | 0.13 | 0.35 | 3.80 | 2.11 | 4.05 | 8.04 |

| Changshan purified soil | 57.32 | 20.28 | 1.50 | - | 0.23 | 0.32 | 3.84 | 2.72 | 5.16 | 8.30 |

|

Huaiming Sodium Soil |

59.90 | 21.83 | 4.12 | - | 0.06 | - | - | - | 3.12 | 8.24 |

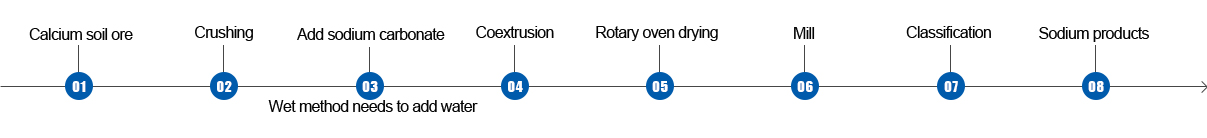

1. The artificial sodiumization process of calcium bentonite is generally:

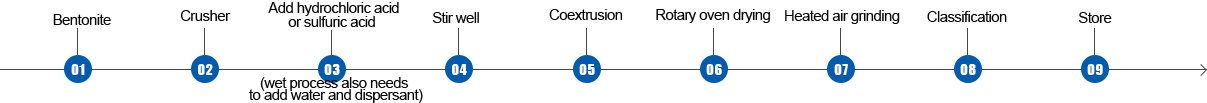

2. The processing flow of active (acid) clay is generally:

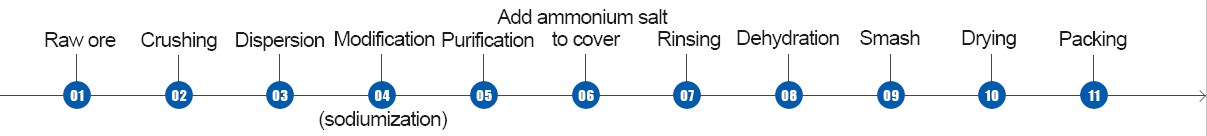

3. The general process of organic bentonite processing is:

Grinding mill selection program

|

Product specifications (mesh) |

200 mesh, D95 | 250 mesh,D90 | 325 mesh,D90 |

| Equipment selection scheme | HC series large modified bentonite special pendulum mill | ||

| Traditional pendulum mill | |||

1. Crushing of raw materials

The bulk material of bentonite is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed bentonite pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07