- all

- product

- blog

- all

- product

- blog

potash feldspar

- 2021-04-25 15:38

- HCM

What is potash feldspar

Potassium feldspar, usually called orthoclase, is red, yellow, white and other colors. It belongs to the monoclinic crystal system and has a Mohs hardness of 6. It is a water-insoluble potassium resource with high potassium content, wide distribution and large reserves. Potash feldspar has the characteristics of low melting point (1150±20°C), long melting interval, and high melting viscosity. It can be divided into orthoclase, plagioclase, and streak feldspar series.

Uses of potash feldspar

Potash feldspar is widely used in industrial sectors such as ceramic blanks, ceramic glazes, glass, electric porcelain, abrasive materials, and potash fertilizers. Potash feldspar in the glass industry, about 50-60% of potash feldspar is used as a raw material for the glass industry. In addition, the ceramic industry uses 30% of the potash feldspar, and the rest is widely used in chemicals, glass fluxes, Ceramic body ingredients, ceramic glaze, enamel raw materials, abrasives, glass fiber, welding rod and other industries.

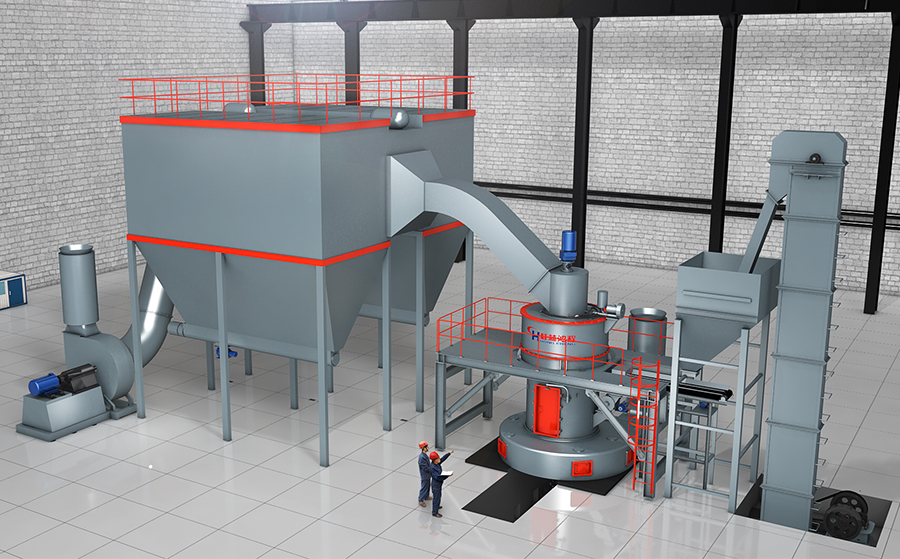

Potash feldspar powder production process

Potassium feldspar raw material composition analysis table

SiO2 |

Al2O3 |

K2O |

64.7% |

18.4% |

16.9% |

Selection scheme for main machine of potash feldspar mill

|

Product specifications (mesh) |

Fine powder processing (80 mesh-400 mesh) |

Deep processing of superfine powder (600 mesh-2000 mesh) |

Equipment selection scheme |

Vertical mill Pendulum mill |

Ultrafine ring roller mill Superfine vertical mill |

1. Crush raw materials

The potash feldspar bulk material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of potassium feldspar are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

|

|

|

HLM series vertical mill |

HLMX series ultrafine vertical mill |

|

|

Large-scale equipment and high output can meet large-scale production. The product has a high degree of sphericalization and better quality, but the equipment investment cost is higher. |

For the large-scale production of ultra-fine powders above 600 mesh, or customers have higher requirements for the particle shape of the powder, the HLMX ultra-fine vertical mill is the better choice. |

|

|

|

|

HCH Ring Roll Superfine Mill |

HC series pendulum mill | |

|

For ultra-fine powders above 600 mesh, the ultra-fine ring roller mill is a highly efficient, energy-saving, economical and practical milling equipment. |

Low investment cost, high output, low energy consumption, stable equipment, low noise; disadvantages: single machine output is degraded, and equipment large-scale is limited. |

Classic case of potash feldspar milling

Processing material: feldspar

Fineness: 200 mesh D97

Output: 6-8t/h

Equipment configuration: 1 HC1700

Hongcheng potash feldspar mill has a very high operating efficiency, reliable quality, and greatly improved efficiency. Since the purchase of the potash feldspar mill produced by Guilin Hongcheng, both in terms of production capacity and unit energy consumption All of the above have greatly improved the efficiency of users' equipment, and created better social and economic benefits for us. It is truly a new type of high-efficiency and energy-saving milling equipment.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07