- all

- product

- blog

- all

- product

- blog

kaolin

- 2021-09-06 15:26

- HCM

Kaolin is a common clay mineral in nature and a very important non-metallic mineral. Because of its white color, it is also called dolomite.

WHAT IS KAOLIN

Kaolin is a common clay mineral in nature and a very important non-metallic mineral. Because of its white color, it is also called dolomite. The pure kaolin is white, fine, soft and soft, with good plasticity, fire resistance, suspension, adsorption and other physical properties. The world is rich in kaolin resources, with a total amount of about 20.9 billion tons, which is widely distributed. Countries such as China, the United States, the United Kingdom, Brazil, India, Bulgaria, Australia, Russia and other countries have high-quality kaolin resources. my country's kaolin mineral resources rank among the top in the world, with 267 proven mineral deposits and proven reserves of 2.91 billion tons.

USES OF KAOLIN

With the continuous economic development, the role of kaolin in social production has become increasingly prominent, and it is an essential mineral raw material for national economic construction. It is also widely used in industrial sectors such as rubber, plastics, refractory materials, petroleum refining, and cutting-edge technology in agriculture and national defense.

1. Paper industry:

Kaolin is used in papermaking, which can give the paper good covering performance and good coating gloss performance. It can also increase the whiteness, opacity, smoothness and printability of the paper, and greatly improve the quality of the paper.

2. Ceramic industry:

Kaolin is used in the field of ceramics, which is conducive to the formation of mullite and improves its chemical stability and sintering strength.

3. Petrochemical industry:

Kaolin can be used as a catalyst filler for petroleum cracking, and kaolin has high purity, which is good for making catalyst carriers.

4. Coating industry:

The main role of kaolin in paint is filler and pigment substitute.

5. Rubber field:

Nano-grade kaolin can improve rubber's performance in terms of elasticity, flex resistance, dimensional stability, compression deformation and other properties.

6. Agriculture field:

The kaolin aqueous solution is used in agricultural fields such as fruit trees, grains, vegetables, etc., which can greatly reduce production costs and reduce the amount of pesticide residues in crops.

KAOLIN POWDER MAKING PROCESS

Kaolin raw material composition analysis table

SiO2 |

Al22O3 |

H2O |

46.54% |

39.5% |

13.96% |

Selection scheme of main machine for kaolin pulverizing

Product specifications (mesh) |

Superfine powder 325 mesh |

Deep processing of superfine powder (600-2000 mesh) |

|

Equipment selection scheme |

Vertical grinding mill or Raymond mill |

|

Remarks: Select the host according to the output and fineness requirements.

1.Crushing of raw materials

The kaolin bulk material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of kaolin are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

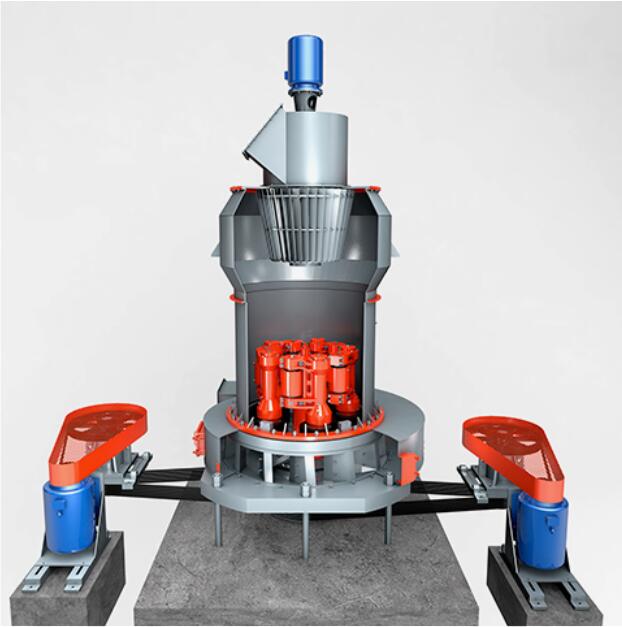

ANALYSIS OF VARIOUS MILLS

|

|

|

| HLM series vertical mill | HLMX series ultrafine vertical mill | |

|

Large-scale equipment and high output can meet large-scale production. Vertical mill has high stability. Disadvantages: high equipment investment costs. |

It can produce 1250 mesh ultra-fine powder at one time, and the supporting multi-level classification system can produce the smallest 3μm powder. The equipment has high efficiency and high degree of spheroidization of the powder, making it an ideal equipment for producing high-quality micropowders. Disadvantages: The equipment investment cost is higher than that of the ring roller mill. |

|

|

|

| HCH Ring Roll Superfine Mill | HC series pendulum mill | |

| The equipment has low investment cost and low energy consumption. It is a cost-effective ultra-fine powder processing equipment. Disadvantages: low output of a single machine, multiple equipment is required for planned production |

Low investment cost, high output, low energy consumption, stable equipment, low noise. Disadvantages: low output of single machine, limited equipment large-scale. |

CLASSIC CASE OF KAOLIN MILLING

Processing materials: pyrophyllite, kaolin

Fineness: 200 mesh D97

Output: 6-8t/h

Equipment configuration: 1 HC1700

Guilin Hongcheng pulverizer is well-known to everyone, and it is a very wise choice to choose to cooperate with such a company with a complete after-sales guarantee system. The Hongcheng kaolin mill is a new equipment that is a replacement of the traditional mill. The output is 30%-40% higher than the traditional Raymond mill. It greatly improves the production efficiency and unit of the unit mill. The output and the finished products produced are very competitive in the market and are very popular in our company.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07