- all

- product

- blog

- all

- product

- blog

Gypsum

- 2021-12-07 15:39

- HCM

What is Gypsum

Gypsum is a monoclinic mineral, the main component is calcium sulfate (CaSO4). Gypsum generally refers to two kinds of minerals: raw gypsum and anhydrite. Raw gypsum is also called dihydrate gypsum, hydrated gypsum or soft gypsum, and is usually dense. Shaped or fibrous, with a Mohs hardness of 2, anhydrite is anhydrous calcium sulfate, usually compact or granular, white, off-white, glassy, and with a Mohs hardness of 3 to 3.5. my country's reserves of gypsum mineral resources are very rich, and the total proven reserves of various types of gypsum are about 57 billion tons, ranking the top in the world.

Uses of Gypsum

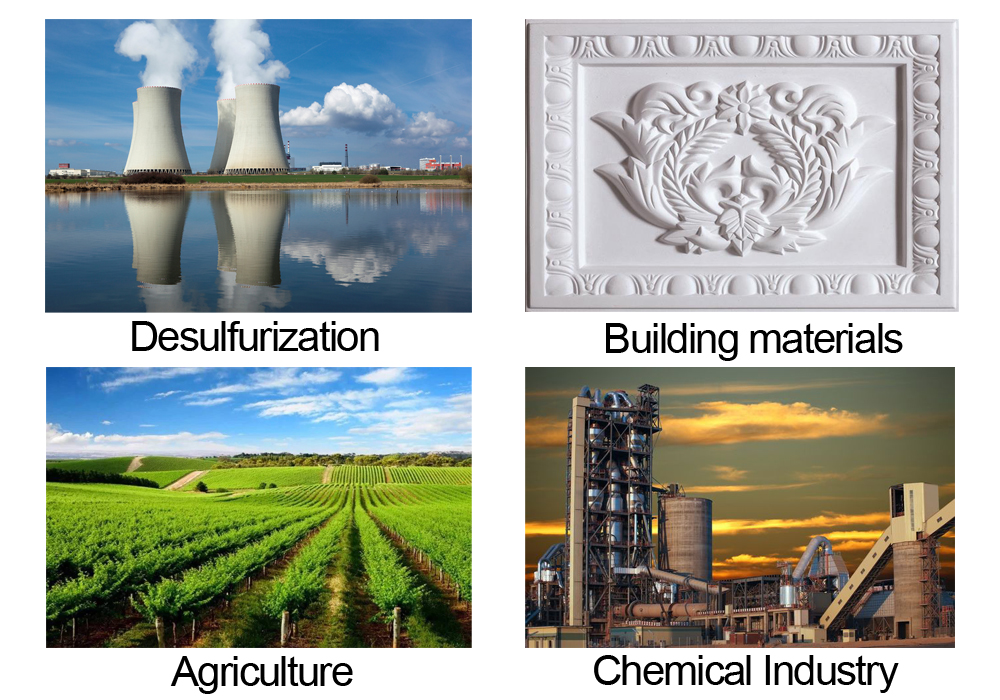

With the rapid development of the national economy, gypsum has been widely promoted and applied in different fields. Gypsum has been highly valued in construction, agriculture, thermal power plants, chemical industries and other fields, forming a huge emerging industry and promoting the rapid development of circular economy.

1. Construction and building materials: the plaster gypsum obtained by calcining gypsum to 170°C is used to coat ceilings, wood boards, etc.; gypsum can be used as cement and cementitious materials in industries such as plastics, rubber, coatings, asphalt, and linoleum. Used as a filler in production; it can also be used as a coagulation and expansion agent, anti-cracking agent, and the main raw material for self-leveling mortar.

2. Chemical industry: gypsum can be used to produce sulfuric acid, with the production of light cement; it can produce ammonium sulfate, with the production of light calcium carbonate.

3. Agriculture: gypsum can be used to improve soil and adjust pH; it can be used as calcium and sulfur compound mineral fertilizer in the cultivation of edible fungi; it can be used as a compound mineral feed additive in poultry and livestock.

4. Thermal power plant field: With the continuous increase in environmental protection, the role of gypsum in thermal power plants has become increasingly prominent. In the desulfurization process, choosing a good desulfurizer is the key to absorbing sulfur dioxide, and limestone can be used as an efficient desulfurizer For use, the smaller the particle size of limestone powder, the more conducive to the absorption of sulfur dioxide, and the more efficiently and quickly the flue gas after combustion can be desulfurized and purified.

Gypsum powder production process

Gypsum raw material composition analysis table

CaO |

SO3 |

H2O+ |

32.5% |

46.6% |

20.9% |

Selection scheme of gypsum powder main machine

Product specifications |

Coarse flour processing (100 mesh-400 mesh) |

Deep processing of fine powder (600 mesh-2000 mesh) |

Equipment selection scheme |

Vertical grinding mill or Raymond mill |

Ultra-fine grinding mill or Superfine grinding mill |

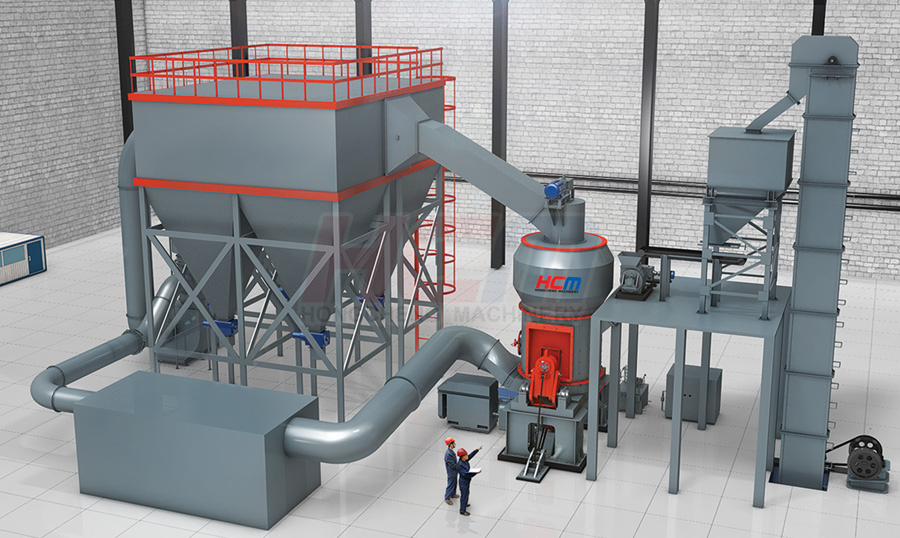

1. Crushing of raw materials

The gypsum bulk material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed gypsum pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected product powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

|

|

|

| HLM series vertical mill | HLMX series ultrafine vertical mill | |

| Large-scale equipment and high output can meet large-scale production. |

For the large-scale production of ultra-fine powders above 600 mesh, or customers have higher requirements for the particle shape of the powder, the HLMX ultra-fine vertical mill is the best choice. | |

| The vertical mill has high stability. | ||

| Disadvantages: high equipment investment costs. |

|

|

|

| HCH Ring Roll Superfine Mill | HC series pendulum mill | |

| For ultra-fine powders above 600 mesh, the ultra-fine ring roller mill is a highly efficient, energy-saving, economical and practical milling equipment. | The investment cost is low, the output is high, the energy consumption is low, the equipment is stable, and the noise is low; the shortcomings are the high maintenance rate of parts and the high labor cost. |

Classic case of gypsum powder making

Processing material: Gypsum

Fineness: 325 mesh D97

Output: 8-10t/h

Equipment configuration: 1 HC1300

Guilin Hongcheng is really doing things, treating people sincerely, doing things steadily, focusing on customers in everything, thinking about what customers think, and eager for customers. Hongcheng gypsum mills are well-known in the industry. It is not only benefited from the excellent product quality of Hongcheng, but also inseparable from the service system of Hongcheng who treats people with sincerity.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07