- all

- product

- blog

- all

- product

- blog

bauxite

- 2021-12-21 16:39

- HCM

What is bauxite

Bauxite, also known as bauxite or bauxite, is a kind of earthy mineral, the main component is alumina, white or off-white, brown yellow or light red due to the iron content. Bauxite is generally formed by chemical weathering or exogenous action. There are few pure minerals, and more or less a small amount of clay minerals, titanic minerals, titanium minerals and detrital heavy minerals. The hardness of bauxite is 1-3, opaque, brittle, insoluble in water, soluble in sulfuric acid and sodium hydroxide solution.

Uses of bauxite

Bauxite is a high-quality aluminum smelting raw material and refractory material. With the development of economy and the progress of science and technology, bauxite has been widely used in deeper fields.

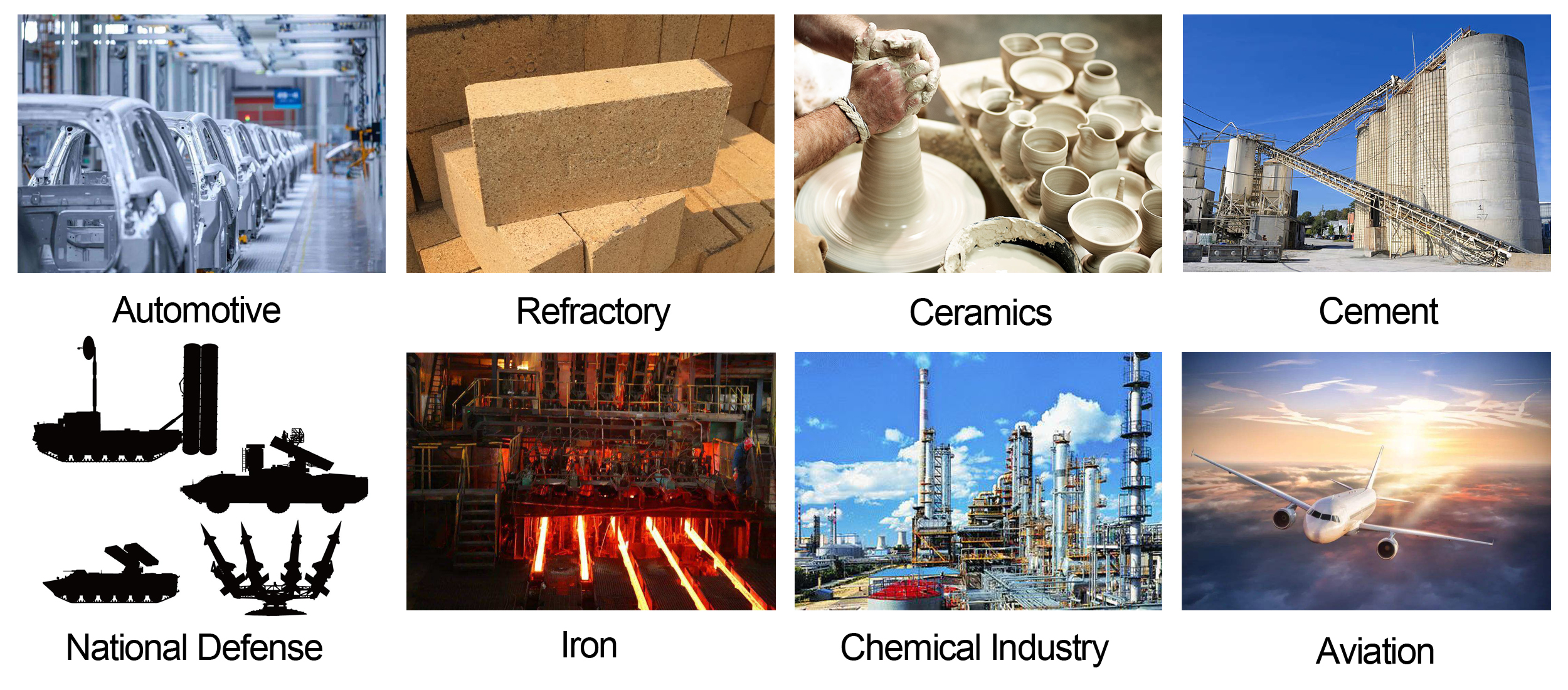

① Aluminum smelting industry: used in national defense, aviation, automobiles, electrical appliances, chemicals, daily necessities, etc.

② Precision casting: bauxite clinker is processed into fine powder and then precision casting is made into a mold. It can be widely used in military, aerospace, communications, instrumentation, machinery and medical equipment departments.

③ Used in refractory products: High bauxite clinker has a refractoriness of up to 1780℃, strong chemical stability and good physical properties. It is a high-quality refractory material.

④ Aluminum silicate refractory fiber: used in steel, non-ferrous metallurgy, electronics, petroleum, chemical, aerospace, atomic energy, national defense and other industries, it has light weight, high temperature resistance, good thermal stability, low thermal conductivity, small heat capacity and resistance Advantages such as mechanical vibration.

⑤ Using magnesia and bauxite clinker as raw materials, adding appropriate binders, it is very effective for pouring steel drums as a whole barrel lining.

⑥ Manufacturing alumina cement, abrasive materials, various compounds that can be used to make aluminum in the ceramic industry and the chemical industry.

Bauxite powder making process

Analysis table of raw material composition of bauxite

|

Al2O3,SiO2,Fe2O3,TiO2,H2O+ As the main ingredient |

S,CaO,MgO,K2O,Na2O, CO2,MnO2 |

Ga,Ge,Nb,Ta,TR,Co,Zr,V, P,Cr,Ni etc. |

Above 95% |

Minor ingredients |

Micro-ingredients |

Selection scheme of bauxite pulverizing host

Product specifications |

Fine powder processing (80 mesh-400 mesh) |

Deep processing of high-fine powder (600 mesh-2000 mesh) |

Equipment selection scheme |

Vertical mill or Raymond mill |

|

Remarks: Choose different types of mill according to the output and fineness requirements.

1. Crushing of raw materials

The large bauxite material is crushed by the crusher to the fineness of the feed material (15mm-50mm) that can enter the mill.

2. Milling

The crushed bauxite pieces are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected product powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

|

|

|

| HC series large pendulum mill | HLMX series ultrafine vertical mill | |

| For coarse powder below 600 mesh, the equipment investment cost is low, and the energy consumption is low. | Large-scale equipment and high output can meet large-scale production. The vertical mill has high stability. | |

| Disadvantages: high equipment investment cost. | ||

|

||

| HCH Ring Roll Superfine Mill | ||

| The production of ultra-fine powder has low energy consumption and low equipment investment cost. The market prospects for large-scale ring roller mills are good. | ||

| Disadvantages: low output. |

Classic case of bauxite powder making

Model: 1 set HLM2400

Processing material: Bauxite

Finished product fineness: 325 mesh D97

Output capacity: 8-10t/h

Guilin Hongcheng has strong strength and solid foundation in the field of production of flour mills, and is an expert in the field of research and development and manufacturing of flour mills. After repeated comparisons and many market investigations, our company decided to choose Hongcheng bauxite mill (HLM2400 vertical mill). The bauxite mill produced by Guilin Hongcheng is equipped with high quality, stable performance and good quality. It can meet the production needs in the field of bauxite powder milling. More importantly, Hongcheng has a team of professional technical and high-quality after-sales maintenance engineers. The bauxite mill was officially put into operation and made great contributions.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07