- all

- product

- blog

- all

- product

- blog

Manganese

- 2021-12-28 16:30

- HCM

What is manganese ore

Manganese is widely distributed in nature, and almost all kinds of ores and silicate rocks contain manganese. There are currently 150 known manganese minerals, among which manganese oxide ore and manganese carbonate ore are of great economic value, which are important industrial minerals of manganese. The main components of manganese oxide ore are MnO2, Mn2O3, Mn3O4, among which pyrolusite and hard manganese ore are very important. The chemical composition of pyrolusite is MnO2, and the manganese content can reach 63.2%. It often contains a small amount of water, silicon dioxide, iron oxide and pyrolusite. The hardness varies with morphology and degree of crystallinity. It is 5-6 for those with obvious crystals, and it is reduced to 1-2 for those with cryptocrystals or massive aggregates. The density is 4.7~5.0g/cm3. The chemical composition of hard manganese ore is hydrated manganese oxide, with the molecular formula nMnO•1MnO2•mH2O. The manganese content is about 45-60%. It often contains impurities such as iron, calcium, copper, and silicon. Hardness: 4-6; Specific gravity: 4.71g/cm³. Manganese carbonate minerals are composed of MnCO3 and often contain iron, calcium, zinc and other elements. There are a lot of rhodochrosite resources in Guizhou, Hunan and Northeast China. It is an important mineral raw material for manganese extraction.

Uses of manganese ore

Manganese ore products include metallurgical manganese ore, manganese carbonate ore powder (an important mineral raw material for manganese smelting), manganese dioxide ore powder for chemical industry, and manganese dioxide ore powder for battery. The metallurgical, light industry and chemical sectors that use manganese ore products have different quality requirements for manganese ore products according to different uses. Chemical and light industry departments’ quality requirements for manganese ore. In the chemical industry, manganese ore is mainly used to produce manganese dioxide, manganese sulfate, potassium permanganate, and secondly to produce manganese carbonate, manganese nitrate and manganese chloride.

Manganese ore products include metallurgical manganese ore, manganese carbonate ore powder (an important mineral raw material for manganese smelting), manganese dioxide ore powder for chemical industry, and manganese dioxide ore powder for battery. The metallurgical, light industry and chemical sectors that use manganese ore products have different quality requirements for manganese ore products according to different uses. Chemical and light industry departments’ quality requirements for manganese ore. In the chemical industry, manganese ore is mainly used to produce manganese dioxide, manganese sulfate, potassium permanganate, and secondly to produce manganese carbonate, manganese nitrate and manganese chloride.

Grade |

MnO2 (≥%) |

Note |

Excellent grade |

80 |

(1) The impurity composition and content of the product should be negotiated between the supplier and the buyer according to different uses; (2) The product should pass a 100-mesh sieve, and the weight under the sieve accounts for more than 95% of the total weight. If the buyer has different requirements, the supplier and the buyer shall negotiate; (3) The wet storage water of the product is not more than 3%, andthe wet storage water is subject to the inspection result when the supplier is packaging. (4) The product must not be mixed with foreign impurities |

First grade |

75 |

|

Second grade |

70 |

|

Third grade |

65 |

|

Fourth grade |

60 |

|

Fifth grade |

55 |

|

Sixth grade |

50 |

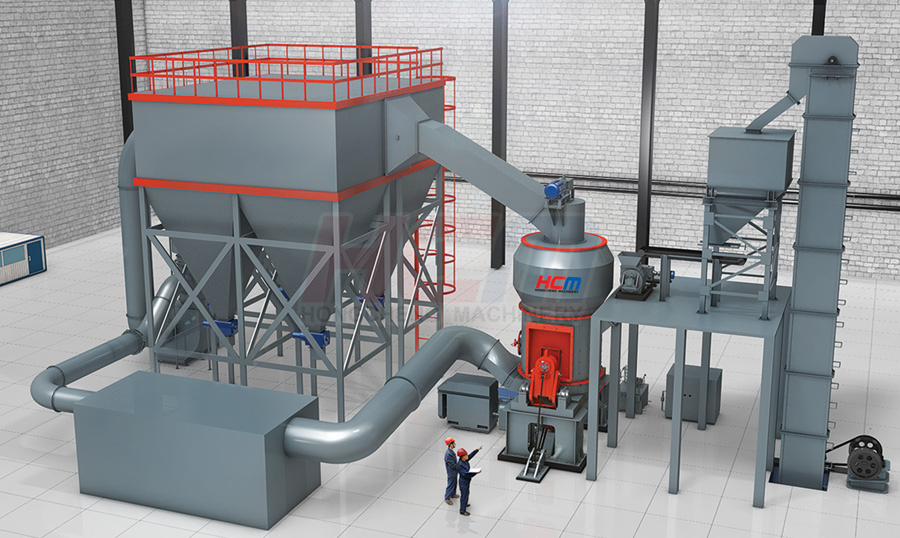

Manganese ore powder production process

Manganese ore powder making selection scheme

|

200 mesh, D80-D90 |

Raymond Mill |

HC1700 and HC2000 large-scale pendulum mills realize low-input and high-output production. |

Vertical Mill |

Large-scale production, the competitiveness of vertical mills above HLM1700 is obvious. |

1. Crushing

The large manganese ore material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of manganese ore are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection

The powder that meets the fineness is separated and collected by the airflow through the pipe into the dust collector. The collected product powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

1. Raymond mill: low investment cost, high output, low energy consumption, stable equipment and low noise;

HC series mill output and energy consumption table

Category |

HC1300 |

HC1700 |

HC2000 |

Output(t/h) |

3-5 |

8-12 |

16-24 |

|

Energy consumption (kwh/t) |

39-50 |

23-35 |

22-34 |

2. Vertical mill: (HLM vertical manganese ore mill) high output, large-scale production, low maintenance rate and high degree of automation. Compared with Raymond Mill, the investment cost is higher.

HLM vertical mill specifications and technical parameters (manganese ore industry)

Model |

HLM1700MK |

HLM2200MK |

HLM2400MK |

HLM2800MK |

HLM3400MK |

Output(t/h) |

20-25 |

35-42 |

42-52 |

70-82 |

100-120 |

Raw material moisture |

≤15% |

≤15% |

≤15% |

≤15% |

≤15% |

Powder fineness |

10 mesh(150μm)D90 |

||||

Powder moisture |

≤3% |

≤3% |

≤3% |

≤3% |

≤3% |

Motor Power(KW) |

400 |

630/710 |

710/800 |

1120/1250 |

1800/2000 |

Classic case of manganese ore powder making

Model: 6 sets HC1700

Material: manganese carbonate

Fineness: 90-100 mesh

Output: 8-10 tons/hour

Songtao Miao Autonomous County is known as China's Manganese Capital. Relying on the unique local manganese ore materials and energy advantages, it has been using the Raymond mill manufactured by Guilin Hongcheng Mining Equipment Manufacturing Co., Ltd. to specialize in the production of electrolytic manganese. It is currently one of the large-scale electrolytic manganese manufacturers in China, with an annual output of up to Twenty thousand tons. The products are widely used in metallurgy, chemical industry, medicine, magnetic materials, electronic communication and other fields, and the products are exported to Europe, America, Southeast Asia and other places.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07