- all

- product

- blog

- all

- product

- blog

Iron ore

- 2022-01-05 15:00

- HCM

What is iron ore

Iron ore is an important industrial source. It is a kind of iron oxide ore. It is a mineral aggregate that contains iron elements or iron compounds and can be used economically. There are many types of iron ore Magnetite, siderite, hematite etc. Iron exists in nature in the form of a compound. Natural iron ore can be gradually separated from iron after crushing, grinding, magnetic separation, flotation, and gravity separation. Therefore, iron ore is important in the field of steel production. The raw materials of iron ore generally less than 50% grade need to be smelted and utilized after beneficiation. At present, combining the development status of the iron and steel industry and the resource characteristics of China's iron ore, the beneficiation technology of China's metallurgical mines must be continuously improved to promote the rapid development of the industry, equipment investment, production costs, power consumption, and steel consumption for crushing and grinding operations Factors such as those will determine the development of the industry and market benefits to a large extent.

Uses of iron ore

The main application field of iron ore is in the steel industry. Recently, steel products are widely used in the national economy and people’s daily life. They are the basic materials necessary for social production and life. Steel is a very important structural material in the country. It occupies an extremely important position in the economy and has become an important pillar of social development.

The output, variety, and quality of steel and steel have always been an important indicator of the development level of a country’s industry, agriculture, national defense, and science and technology. Among them, iron, as the basic raw material of the steel industry, is an important raw material supporting the entire steel industry. Iron ore It plays a huge role in the iron and steel industry, and can be smelted into pig iron, wrought iron, ferroalloy, carbon steel, alloy steel, special steel, etc., and pure magnetite can also be used as a catalyst for the synthesis of ammonia.

In order to give full play to the resource advantages of iron ore, the beneficiation process and the beneficiation equipment need to keep pace with the times, in view of the characteristics of iron ore with more lean ore, less rich ore, more associated minerals, complex ore composition, and mostly finer ore embedded particle size. In order to improve the quality and quantity of iron products and the comprehensive economic benefits of the enterprise, it’s only by introducing the old and bringing forth the new.

Iron ore powdering process

Iron ore raw material composition analysis table

Ingredients\Variety |

Fe content |

O content |

H2O content |

Magnetite |

72.4% |

27.6% |

0 |

Hematite |

70% |

30% |

0 |

Limonite |

62% |

27% |

11% |

Siderite |

The main ingredient is FeCO3 |

||

Selection scheme of iron ore grinding mill

Product specifications |

Fineness: 100-200 mesh |

Equipment selection scheme |

Vertical grinding mill or Raymond mill |

1. Crushing

The large iron ore material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

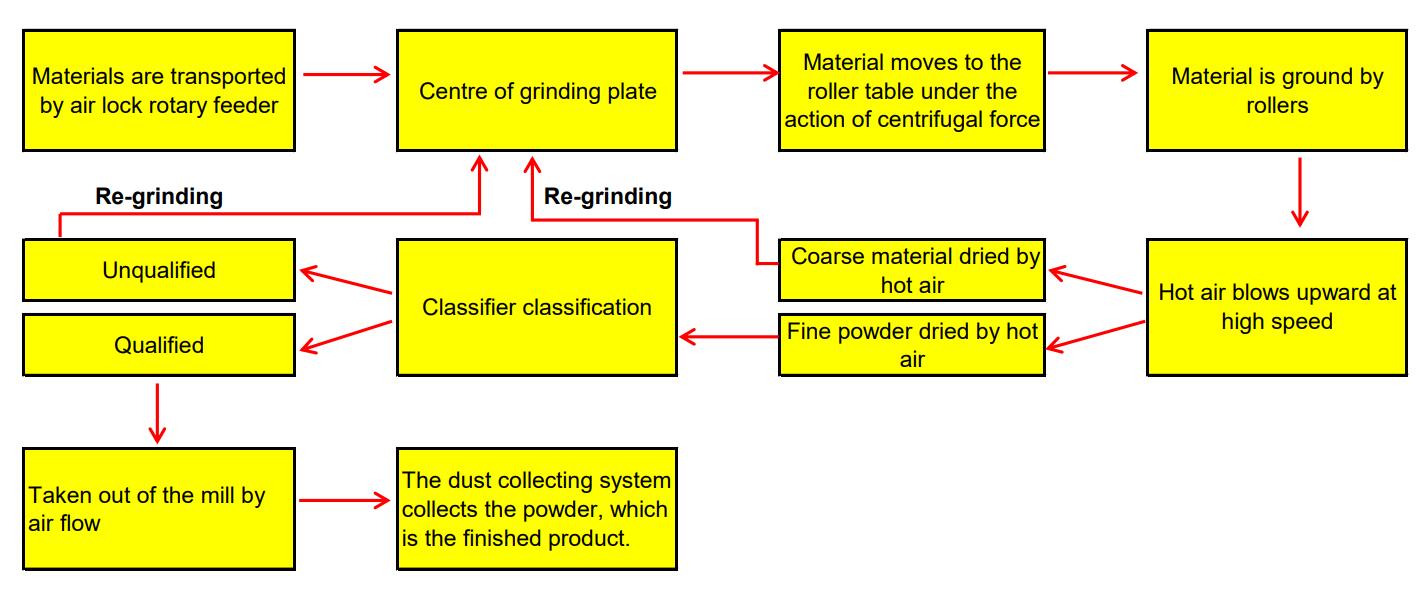

2. Milling

The crushed small iron ore materials are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection

The powder that meets the fineness is separated and collected in the dust collector through the pipeline with the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

·

|

|

|

| HC series large pendulum mill | HLMX series ultrafine vertical mill | |

| For coarse powder below 600 mesh, the equipment investment cost is low, and the energy consumption is low. | Large-scale equipment and high output can meet large-scale production. The vertical mill has high stability. Disadvantages: high equipment investment cost. |

Classic case of iron ore milling

Model: 1SET HLM21

Processing raw materials: Iron ore

Finished product fineness: 200 mesh D90

Equipment output: 15-20 tons/hour

From intention ordering, on-site inspection, production, debugging, to installation, the HCM engineers are dedicated and responsible. Not only have they successfully completed the delivery tasks, but the equipment is operating in a good condition, with stable operation, reliable performance, and production. The efficiency is very high, and the energy saving is also environmentally friendly. We are very satisfied and have confidence in HCM equipment.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07