- all

- product

- blog

- all

- product

- blog

copper ore

- 2022-01-07 14:55

- HCM

What is copper ore

Copper ore is a collection of copper sulfides or oxides and other minerals. It can react with sulfuric acid to produce blue-green copper sulfate. In nature, there are more than 280 copper-bearing minerals, mainly 16 types. Among them, natural copper, chalcopyrite, chalcocite, azurite, malachite and other minerals are more common. The world’s proven copper ore reserves are about 600 million tons. my country has many famous copper mines. The copper ore has been beneficiated into a copper concentrate or copper ore with a higher copper grade. Copper concentrate is required After smelting, it can become refined copper and copper products.

Uses of copper ore

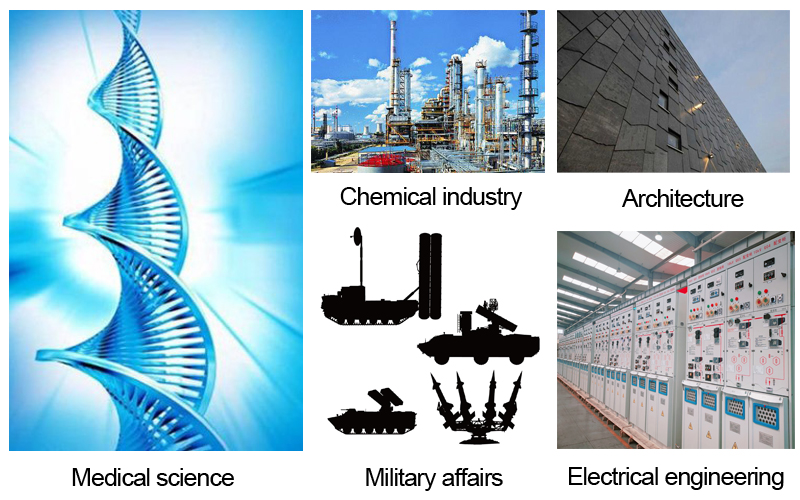

The application of copper has a very long history and is closely related to human production and life. It is second only to aluminum in the consumption of non-ferrous metal materials in my country. At present, it is widely used in electrical, light industry, machinery manufacturing, construction industry, defense industry, etc. field.

1. Electrical industry: The electrical and electronic industries are areas where copper applications are very large, accounting for more than half of the total consumption. It can be used to produce various cables and wires, motors and transformers, switches, manufacturing industrial valves and accessories, meters, and sliding Bearings, molds, heat exchangers, pumps, etc.

2. Chemical industry: widely used in the manufacture of vacuum vessels, distillation pots, brewing pots, etc.

3. National defense field: can be used to manufacture bullets, shells, gun parts, etc.

4. Construction field: can be used to make various pipes, pipe fittings, decorative devices, etc.

5. Medical field: It is medically proven that copper has a strong anti-cancer function and bactericidal effect. Chinese medical inventors have developed corresponding anti-cancer drugs and have been clinically successful. I believe that in the future, copper will create miracles in medicine.

Copper ore powdering process

Copper ore raw material composition analysis table

Cu |

Fe |

S |

34.56% |

30.52 |

34.92 |

Selection scheme of copper ore pulverizing host

Product specifications |

Coarse powder processing (20 mesh-300 mesh) |

Deep processing of fine powder (1250 mesh) |

Equipment selection scheme |

Vertical grinding mill or Raymond mill |

|

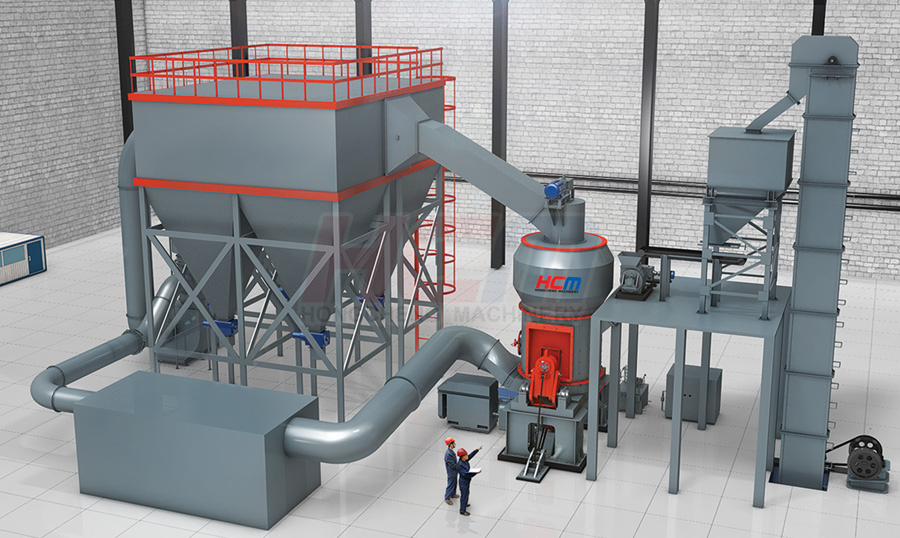

The copper ore bulk material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of copper ore are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collection

The powder that meets the fineness is separated and collected in the dust collector through the pipeline with the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

·

|

|

|

| HC series large pendulum mill | Raymond Mill | |

The investment cost is low, the output is high, the energy consumption is low, the equipment is stable, and the noise is low; the shortcomings are the high maintenance rate of parts and the high labor cost. |

Low investment cost, high output, low energy consumption, stable equipment, low noise; for processing fine powder above 400 mesh, or as a primary crushing equipment for jet mills, pendulum mills are an ideal choice for high cost performance. | |

|

||

| HLM series vertical mill | ||

| Large-scale equipment and high output can meet large-scale production. The vertical mill has higher stability. Disadvantages, high equipment investment costs. |

Classic case of copper ore milling

Model: 1 HLM21

Processing raw materials: copper ore

Fineness: 325 mesh D97

Output: 8-10t/h

Guilin Hongcheng equipped our company with scientific and reasonable copper ore powder production line supporting equipment. In the powder production site, the equipment is very powerful, stable in performance, reliable in quality, small in area, simple in operation, and cost-effective. A high-yield, high-efficiency, energy-saving and environmentally-friendly copper-iron ore processing equipment.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07