- all

- product

- blog

- all

- product

- blog

Grain slag processing

- 2022-01-18 16:24

- HCM

What is grain slag

Grain slag is a product discharged from blast furnaces when iron and steel enterprises smelt pig iron, after melting non-ferrous components in iron ore, coke, and ash in injected coal. Most of them are crystalline blocks, honeycombs or rods, mainly fine particles of vitreous body, light yellow (a small amount of dark green crystals), vitreous or silky luster, Mohs hardness of 1~2, (natural accumulation) specific gravity 0.8~1.3t/m3. There are mainly two ways of water quenching in slag pool and water quenching in front of furnace. It has potential hydraulic cementing properties, and can show hydraulic cementing properties under the action of cement clinker, lime, gypsum and other activators. Therefore, it is a high-quality cement raw material.

Use of grain slag

1. Application of grain slag in cement industry:

With potential hydraulic cementitious properties, it can be used as cement admixture or made into clinker-free cement. The types of cement made are slag portland cement, gypsum slag cement, lime slag cement, etc.

2. Application of grain slag in commercial concrete:

As a mineral admixture of concrete, grain slag micropowder can be directly added to commercial concrete in place of cement in an equal amount. According to the difference in activity and specific surface area, the performance of concrete mixed with grain slag micropowder in a certain proportion is significantly improved. Grain slag powder is especially suitable for special projects such as high-rise buildings, dams, airports, underwater and underground buildings.

Grain slag milling process

Comparison of chemical composition of grain slag from some Chinese steel companies (%)

Composition |

CaO |

SiO2 |

Al2O3 |

MgO |

Fe2O3 |

MnO |

Ti |

S |

K |

M |

Angang |

38.90 |

33.92 |

13.98 |

6.73 |

2.18 |

0.26 |

0.58 |

|||

Gangang |

37.56 |

32.82 |

12.06 |

6.53 |

1.78 |

0.23 |

0.46 |

|||

Jigang |

36.76 |

33.65 |

11.69 |

8.63 |

1.38 |

0.35 |

0.56 |

1.67 |

||

Shougang |

36.75 |

34.85 |

11.32 |

13.22 |

1.38 |

0.36 |

0.58 |

1.71 |

1.08 |

|

Baogang |

40.68 |

33.58 |

14.44 |

7.81 |

1.56 |

0.32 |

0.50 |

0.2 |

1.83 |

1.01 |

Wugang |

35.32 |

34.91 |

16.34 |

10.13 |

0.81 |

- |

1.71 |

1.81 |

0.89 |

|

Magang |

33.26 |

31.47 |

12.46 |

10.99 |

2.55 |

- |

3.21 |

1.37 |

1.65 |

1.00 |

Selection scheme of grain slag grinding mill

Product Specifications |

Finished fineness:420㎡/kg |

Equipment selection scheme |

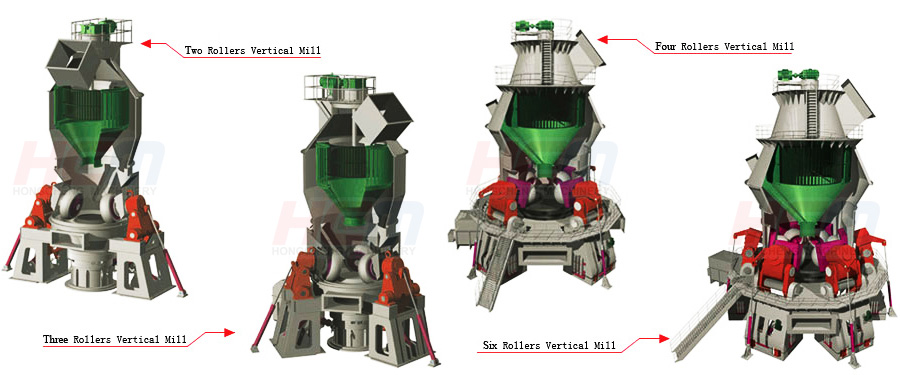

Vertical mill |

1. Drying

The grain slag steel slag is dried by drying the raw materials by means of a dryer or hot air through the mill according to the moisture content.

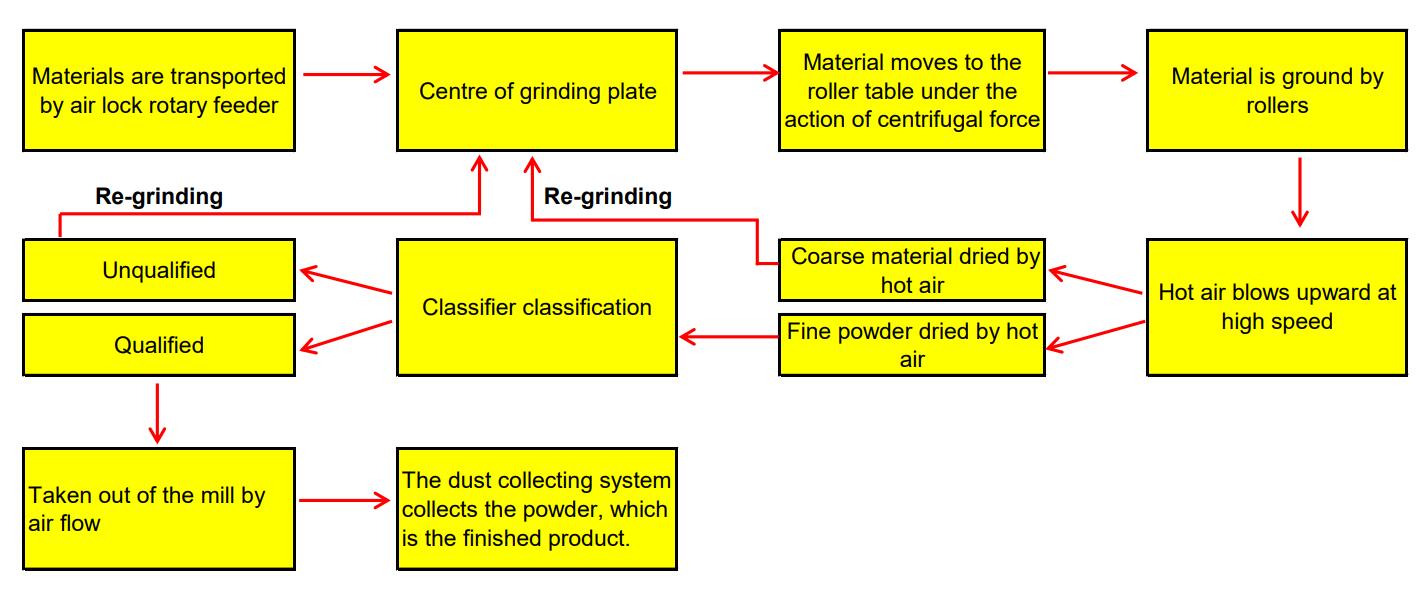

2. Grinding

The crushed grain slag small pieces of material are sent to the storage hopper through the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

3. Classifying

The pulverized materials are classified by the classification system, and the unqualified powders are classified by the classifier and then returned to the main engine for re-grinding.

4. Collection

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then uniformly packed by a powder tanker or an automatic baler.

Analysis of various mills

Vertical mill:

The equipment is large and the output is high, which can meet the large-scale production. The vertical mill has high stability. Disadvantage, equipment investment cost is high.

Classic case of grain slag milling

Model: 1 set of HLM21

Processing raw material: slag

Finished product fineness: 200 mesh D90

Equipment output: 15-20 t/h

After more than ten years of active exploration and research and development, Guilin Hongcheng technology R&D team has finally developed a series of water slag mills with significant energy saving, low carbon and environmental protection after continuous exploration and drilling. Guilin Hongcheng water slag mills responded positively The call of the national energy conservation and emission reduction policy meets the production needs of environmentally friendly production and effective energy saving, and provides customers with advanced, cutting-edge and high-tech milling technology for the water slag milling production line. Loved and welcomed.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07