- all

- product

- blog

- all

- product

- blog

Cement clinker processing

- 2022-01-24 16:24

- HCM

What is Cement Clinker

Cement clinker is a semi-finished product obtained from limestone, clay and iron raw materials as the main raw materials. In the cement industry, the main chemical components of the commonly used Portland cement clinker are calcium oxide, silica and a small amount of alumina and iron oxide. The main mineral composition is tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium ferric aluminate. Portland cement clinker and appropriate amount of gypsum are ground together to make Portland cement.

The use of cement clinker

At present, cement clinker is widely used in civil and industrial construction projects, such as cementing in oil and gas fields, large-volume dams in water conservancy projects, military emergency repair projects, and can also be used as acid-resistant and refractory materials. In addition, it can also replace wood and steel for various occasions, such as utility poles, railway sleepers, oil and gas pipelines, crude oil storage and gas storage tanks, etc.

Cement clinker milling process

Portland cement clinker raw material composition analysis table

CaO |

SiO2 |

Fe2O3 |

Al2O3 |

62%-67% |

20%-24% |

2.5%-6.0% |

4%-7% |

Cement clinker pulverizing host selection scheme

Product Specifications |

220-260㎡/kg(R0.08≤15%) |

Equipment selection scheme |

Vertical mill |

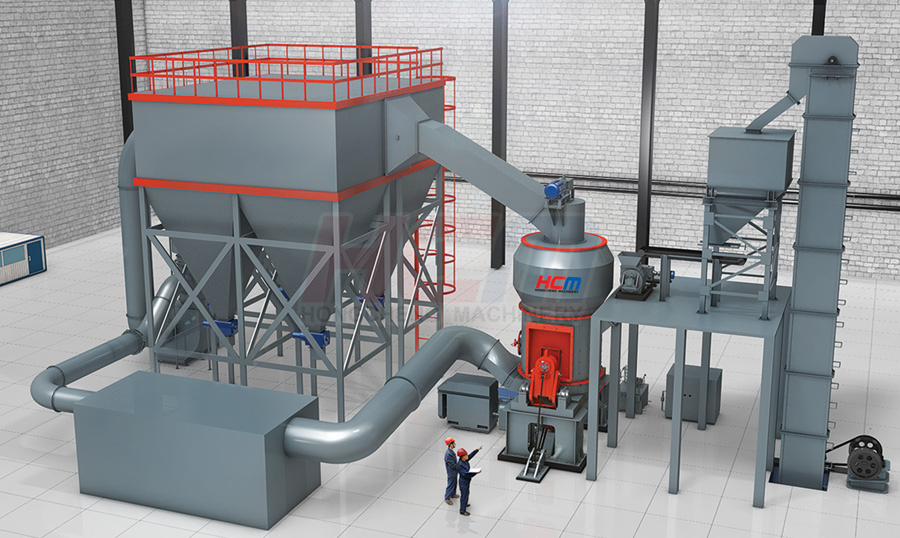

1. Crushing

The cement clinker material is crushed by the crusher to the feed fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of cement clinker are sent to the storage hopper through the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

3. Classifying

The pulverized materials are classified by the classification system, and the unqualified powders are classified by the classifier and then returned to the main engine for re-grinding.

4. Collection

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then uniformly packed by a powder tanker or an automatic baler.

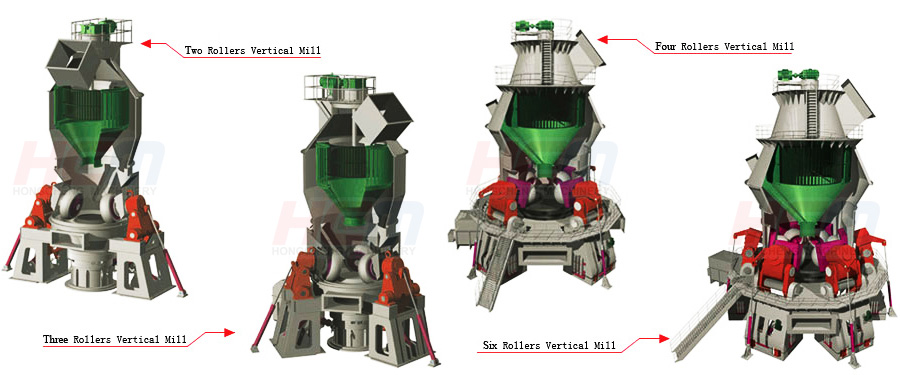

Analysis of various mills

Vertical mill:

The equipment is large and the output is high, which can meet the large-scale production. The vertical mill has high stability. Disadvantage, equipment investment cost is high.

Classic case of cement clinker milling

Guilin Hongcheng cement clinker mill is durable and has excellent equipment products. Among them, the concept of environmental protection is very prominent. Basically, there is very little dust overflow in the milling production workshop. The overall environment is clean and tidy, and the power consumption is also very low. Language is very important, which directly reduces production and operating costs and saves a lot of expenses for milling enterprises.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07