- all

- product

- blog

- all

- product

- blog

Cement raw material processing

- 2022-01-25 16:28

- HCM

What is cement raw meal

Cement raw meal is made of calcareous raw materials, clay raw materials and a small amount of calibration raw materials (sometimes with addition of mineralizers, crystal seeds, etc., and coal is added in shaft kiln production) in proportion and ground to a certain fineness. According to the different cement production methods, raw meal can be divided into raw meal slurry, raw meal powder, raw meal ball and raw meal block, etc. They are respectively suitable for wet, dry, semi-dry and semi-wet production requirements. . Regardless of the form of raw meal, the chemical composition is required to be stable, and the fineness and moisture must meet the requirements of different production methods, so as not to affect the kiln calcination and clinker quality.

The use of cement raw meal

1. Use of raw meal powder: dry rotary kiln and vertical kiln calcined by white raw meal method.

2. Black raw meal: The raw meal contains all the coal required for calcination. For shaft kilns calcined by the all-black raw meal method.

3. Semi-black raw meal: only a part of the coal required for calcination is contained in the raw meal. For shaft kilns calcined by semi-black raw meal method.

4. Raw pulp: Raw meal used in wet production. Generally, the moisture content is about 32% to 40%.

Cement raw meal milling process

Raw material composition analysis table of raw materials and coal ash

Raw material |

Loss |

SiO2 |

Al2O3 |

Fe2O3 |

CaO |

MgO |

R2O |

Other |

Total |

Limestone |

43.56 |

2.45 |

0.36 |

0.21 |

50.48 |

2.13 |

0.24 |

0.57 |

100.00 |

Fly ash |

1.45 |

53.44 |

26.87 |

6.73 |

7.23 |

1.36 |

1.26 |

1.66 |

100.00 |

Sandstone |

0.69 |

90.68 |

1.47 |

1.20 |

2.15 |

0.12 |

0.30 |

3.39 |

100.00 |

Iron powder |

6.00 |

18.25 |

2.36 |

62.78 |

2.54 |

1.98 |

1.33 |

4.76 |

100.00 |

Coal ash |

53.09 |

26.60 |

5.12 |

7.15 |

1.78 |

1.23 |

5.03 |

100.00 |

Cement raw meal pulverizing host selection scheme

Product Specifications |

R0.08<14% |

Equipment selection scheme |

Vertical mill |

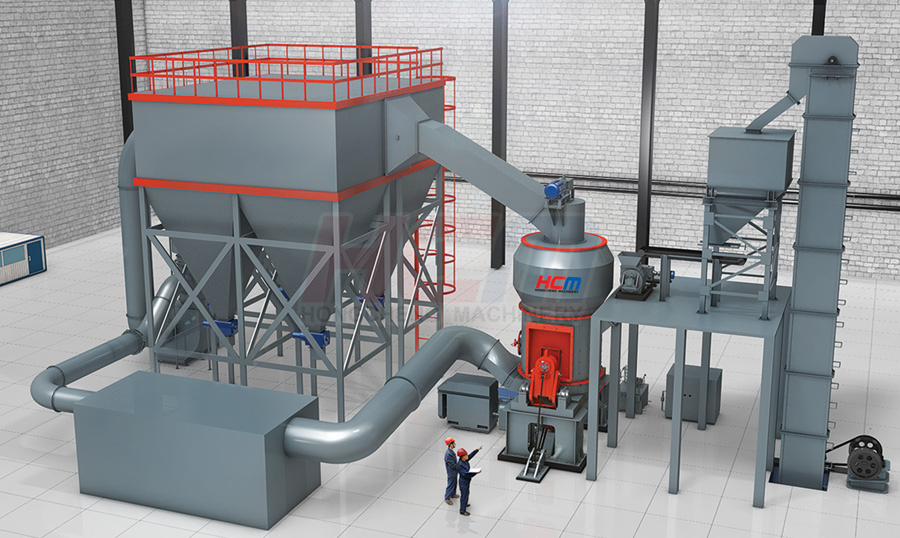

1. Crushing

The raw cement material is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed cement raw materials are sent to the storage hopper through the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively through the feeder for grinding.

3. Classifying

The pulverized materials are classified by the classification system, and the unqualified powders are classified by the classifier and then returned to the main engine for re-grinding.

4. Collection

The powder that meets the fineness enters the dust collector through the pipeline with the air flow for separation and collection, and the collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then uniformly packed by a powder tanker or an automatic baler.

Analysis of various mills

Vertical mill:

The equipment is large and the output is high, which can meet the large-scale production. The vertical mill has high stability. Disadvantage, equipment investment cost is high.

Classic case of cement raw meal milling

The model and number of the equipment: 1 HLM21

Processing raw material: Cement raw meal

Finished product fineness: 200 mesh D90

Equipment output: 15-20 tons/hour

Guilin Hongcheng cement raw meal mill has stable performance and high quality, especially the concept of environmental protection is very prominent. The residual air outlet of the mill is equipped with a pulse dust collector, and the dust collection efficiency reaches 99.9%. All positive pressure parts of the main machine are installed. The sealing treatment is basically realized, and dust-free processing is basically realized. At the same time, in terms of production capacity and unit energy consumption, the pulverizer greatly improves the use efficiency of the equipment, which greatly saves the operating cost for the pulverizing enterprise, and the market feedback effect ideal.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07