- all

- product

- blog

- all

- product

- blog

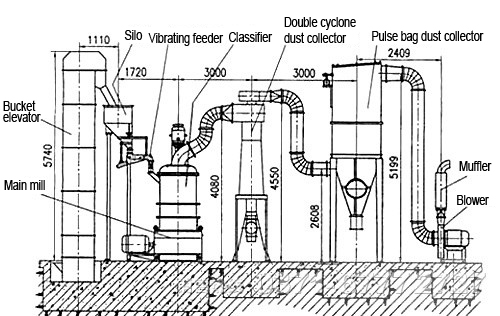

Diagram of attapulgite mill

- 2022-06-09 14:08

- HCM

Attapulgite mill

Clay minerals are abundant in nature and have good mechanical properties and thermal stability. They are widely used in the preparation of fireproof materials, composite materials and electrode materials. Attapulgite is one of the clay minerals, with a Mohs hardness of 2-3, but it increases in hardness after heating, has strong water absorption, is widely distributed, and has large uses. participate. Attapulgite mill is the equipment for powder processing, which can make the mineral more fully utilized and reflect the economic value. Guilin Hongcheng is a professional attapulgite mill manufacturer. Today, I will introduce the diagram of attapulgite mill.

Diagram of attapulgite mill

When the attapulgite micro-powder grinding equipment is working, the main machine drives the main shaft and each layer of turntables to rotate through the reducer, so that dozens of ring rollers roll and rotate in the grinding ring raceway. The attapulgite that can meet the feeding size is sent to the storage bin by the elevator, and then the material is uniformly, quantitatively and continuously sent to the middle of the upper turntable by the vibrating feeder, and the attapulgite material is scattered under the action of centrifugal force. The periphery of the grinding ring falls into the raceway of the grinding ring to be punched, rolled, ground and crushed by the ring roller.

After being pulverized by the first layer, it falls into the second layer for finer grinding, and then enters the third layer for grinding to achieve the desired particle size. The main process of the equipment has been basically completed. For its subsequent process, it is subjected to powder selection and dust removal of production operations. The high-pressure centrifugal fan sucks the external air into the machine by suction, and brings the powder after the third layer pulverization into the classifier. , and the fine powder enters the cyclone powder collector with the air flow and is discharged from the discharge valve at the lower part of it, which is the finished product.

On the other hand, the airflow with a small amount of fine dust is purified by the pulse dust collector and discharged through the fan and the muffler.

The entire grinding process of the attapulgite mill produced by Guilin Hongcheng is scientific and reasonable, and it can effectively discharge the generated dust. The powder can be very popular in the market. Overall, the craftsmanship is mature and worth buying

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07