- all

- product

- blog

- all

- product

- blog

Details

BARITE POWDER CHINA LARGE VERTICAL RAYMOND MILLING BY EXPERIENCED MANUFACTURERS

Barite is a non-metallic mineral product with barium sulfate (BaSO4) as the main component, with a Mohs hardness of 3 to 3.5. Barite is chemically stable, insoluble in water and hydrochloric acid, non-magnetic and toxic, and can absorb X-rays and γ- rays. Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

-

Details -

Parameters -

Case -

Maintenance -

Inquiry

INTRODUCTION OF PRODUCT

Barite is a very important non-metallic mineral raw material and has a wide range of industrial uses.

① Drilling mud weighting agent: In some oil and gas well drilling, adding barite powder to the mud is an effective measure to increase the proportion of mud, and it is the most commonly used measure in drilling operations that can effectively avoid frequent blowout accidents.

② Lithopone pigment: heating barium sulfate, using a reducing agent to reduce to barium sulfide (BaS), and then reacting with zinc sulfate (ZnSO4) to obtain a mixture of barium sulfate and zinc sulfide (BaSO4 accounts for 70%, ZnS accounts for 30%) %) is the lithopone pigment. It can be used as a raw material for paints and painting pigments. It is a commonly used high-quality white pigment.

③ Various barium compounds: Barium oxide, barium carbonate, barium chloride, barium nitrate, precipitated barium sulfate, barium hydroxide and other chemical raw materials can be produced with barite as raw material.

④ Used in industrial fillers: In the paint industry, barite powder filler can increase the thickness, strength and durability of the paint film.In the fields of paper, rubber, and plastics, barite can improve the hardness, abrasion resistance and aging resistance of rubber and plastics; lithopone pigments are also used to make white paints.

⑤ Mineralizer for cement industry: The use of barite and fluorite composite mineralizer in cement production has obvious effects on promoting the formation of C3S and activating C3S, and the quality of clinker has been improved.

⑥ Anti-ray cement, mortar and concrete: Barite is used to absorb X-rays, and barite is used to make barium cement, barite mortar and barite concrete to replace metal lead plates to shield nuclear reactors and build scientific research , X-ray-proof buildings in hospitals.

⑦ Road construction: The mixture of rubber and asphalt containing about 10% barite has been successfully used in parking lots and is a durable paving material.

⑧ Others: barite and oil are blended and coated on cloth to make tarpaulin; barite powder is used to refine kerosene; it is used as a contrast agent for the digestive tract in the pharmaceutical industry; it can also be used to make pesticides, leather, fireworks, etc. In addition, barite is also used to extract metal barium, as a getter and binder for televisions and other vacuum tubes. Barium is alloyed with other metals (aluminum, magnesium, lead, calcium) and used in bearing manufacturing.

BARITE POWDER CHINA LARGE VERTICAL RAYMOND MILLING is a large-scale product based on the company's HC1700 vertical pendulum mill. This series of mills is a large-scale environmental protection mill independently developed by Guilin Hongcheng Mining Equipment Manufacturing Co., Ltd., covering 5 invention patents. The fineness range of its products is between 38-180μm (80-400 mesh), which can meet the domestic industrial policy and the expanding demand for industrialized scale production, make up for the blank of my country's large-scale pendulum mill, and expand the pendulum mill The application field of the powder machine has greatly improved the efficiency of the user's equipment in terms of production capacity and unit energy consumption, and its technical level will be at the domestic advanced level.

This product is suitable for grinding activated carbon and other non-flammable and explosive materials with Mohs hardness below 7 and humidity within 6%.

Finished product size: 38-180μm

Production capacity: 3-90t/h

ADVANTAGES AND FEATURES

New type of spide-arm featured in compact structure. It can be maintained New type of spide-arm featured in compact structure. It can be maintainedwithout disassembly, which save the maintenance time. |

Adopt maintenance-free oil seal technology, screw seal and skeleton oil sealmulti-layer barrier, limited to prevent dust from entering, can achieve add lubri-cating oil per 500~800 hours, reduce the maintenance cost. |

|

Unique high chromium alloy material technology, the use time is nearly 3 times of the industry standard. |

Forced turbine classification technology. The particle size of finished products can be adjusted infinitely between 80~400 mesh. |

|

Off-line pulse dust collection system, dust collection rate up to 99.9%. |

MILL STRUCTURE & WORKING PRINCIPLE

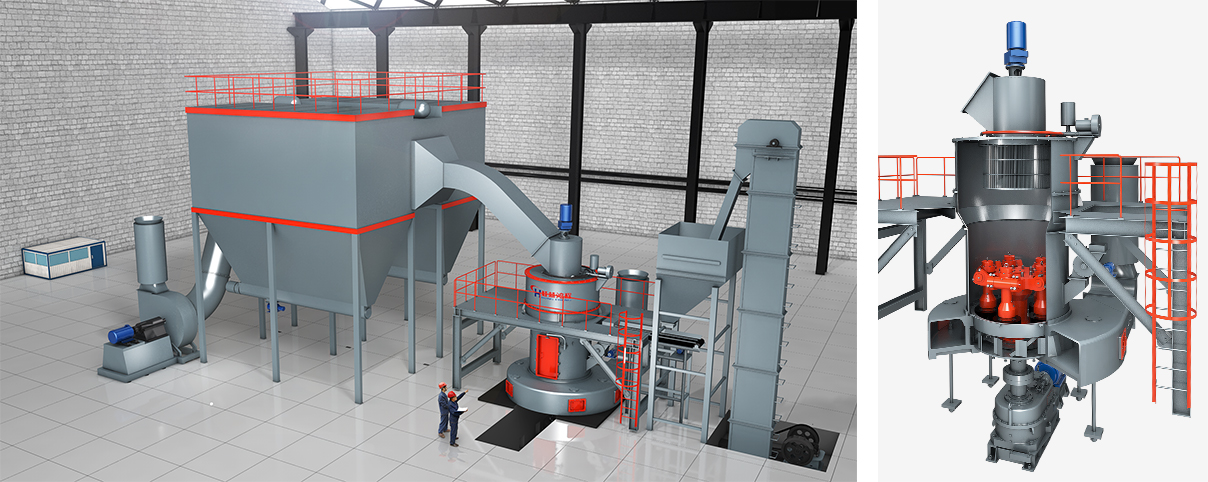

HC china large milling consists of mill system, classifying system, screening, collecting system and other components. The mill system adopts the structure of integral casting base, which can be used as shock absorbing foundation. The classifying system adopts mandatory turbine classifier structure and the collecting system adopts pulse collection.

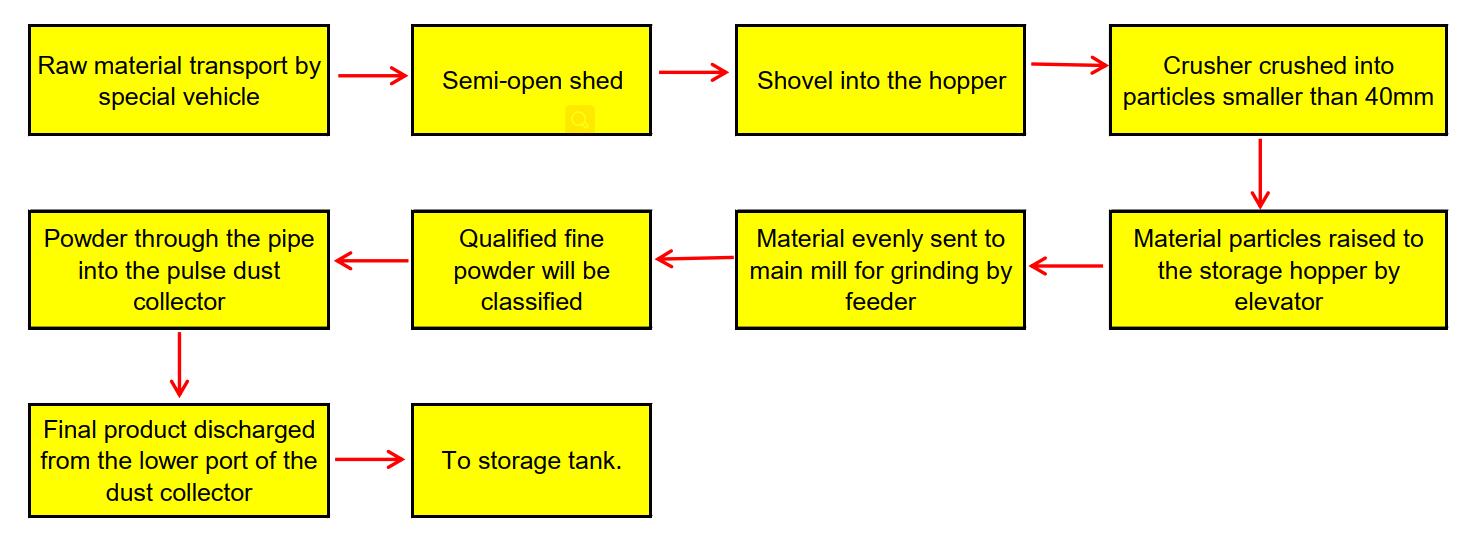

BARITE POWDER PRODUCTION PROCESS

1. Crushing of raw materials

The large pieces of barite are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Grinding

The crushed small pieces of barite are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. The collection of finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then is packaged by a powder tanker or an automatic baler.

TECHNICAL DATA

| Model | Roller Nomber |

Ring Diameter (mm) |

Max. Feeding (mm) |

Fineness (mm) |

Capacity (t/h) |

Total Power (kw) |

| HC1900 | 5 | 1900 | 40 | 0.038-0.18 | 10-35 | 555 |

| HC2000 | 5 | 2000 | 40 | 0.038-0.18 | 15-45 | 635-705 |

Note:

1. The Models above are equiped with newly designed spider-arm structure.

2. The capacity is for limestone powder, and specification is just a reference. The actual production depends on these materials being processed.

SUCCESSFUL CASES

BARITE PENDULUM GRINDING MILL MACHINE MICRONIZATION PROCESS PROJECT

Processing material: barite

Fineness: 325 mesh D97

Output: 8-10t/h

Equipment configuration: 1 HC1300

OTHER RELATED GRINDING MILL RECOMMENDATIONS

ULTRAFINE GRINDER RAW VERTICAL TURBINE TYPE BARITE RAYMOND GRINDING MILL CHINA COMPLETE SUPER FINE TALC ENERGY EFFICIENT NONMETALLIC

GRINDING MILL FACTORY EQUIPMENT MANUFACTURER GRINDING MILL MANUFACTURING PRICE

- Detailed introduction of Raymond mill: Blade + grinding roller + grinding ring to produce fine powde

- GUILIN HONGCHENG TITANIUM DIOXIDE PENDULUM RAYMOND ROLLER BOWL MILL

- MANGANESE ORE DRYER MANUFACTURES MnO RAYMOND ROLLER MILL FOR SALE

- CHINA CHEAP 5R MATTE ORE MIKRO POWDER RAYMOND GRINDING MILL SALE PRICE