- all

- product

- blog

- all

- product

- blog

talc

- 2021-03-25 11:27

- HCM

What is talc

Talc is a common silicate mineral, belonging to a trioctahedral mineral, and its structural formula is (Mg6)[Si8]O20(OH)4. Talc is a hydrothermal alteration mineral. Magnesium-rich minerals often turn into talc through hydrothermal alteration, so talc often presents the illusion of olivine, enstatite, amphibole, tremolite and other minerals. Talc is one of the minerals. It is buried in the ground together with serpentine containing asbestos, so it often contains asbestos in its natural form. Talc is generally lumpy, leaf-like, fibrous or radial. It is very soft and has a slippery feel. Talc is soft, its Mohs hardness coefficient is 1~1.5, it has a slippery feel, {001} cleavage is very complete, it is easy to split into thin slices, the natural angle of repose is small (35°~40°), and it is extremely unstable. The rock is silicified and talcized magnesite, magnesite, lean ore or dolomitic marble, except for a few moderately stable, generally unstable, joints and fissures are developed, and the physical and mechanical properties of the ore and surrounding rock affect the mining process The impact is great.

Uses of talc

Talc has excellent physical and chemical properties such as lubricity, anti-sticking, flow aid, fire resistance, acid resistance, insulation, high melting point, chemical inactivity, good hiding power, softness, good gloss, and strong adsorption. Therefore, talc has a wide range of uses in cosmetics, medicine, papermaking, plastics and other fields.

Cosmetics field

Used in various emollient powder, beauty powder, talcum powder, etc. It has the effect of blocking infrared rays, so it enhances the sunscreen and anti-infrared properties of cosmetics.

Medicine-food field

Used as additives for pharmaceutical tablets, pharmaceutical powders (such as argafen powder), sugar coating, prickly heat powder, Chinese medicine prescriptions, food additives, release agents, etc. It has the characteristics of non-toxic, odorless, high whiteness, good compatibility, strong gloss, soft taste and strong smoothness.

Coating field

Used for white body pigments and various water-based, oil-based, resin industrial coatings, primers, protective paints, etc. Increase the stability of the product shape.

Papermaking field

It is used as filler for all kinds of paper and cardboard, wood asphalt control agent. It can achieve smooth and delicate paper, save raw materials, and improve the service life of the grease net.

Plastic field

It is used as a filler for polypropylene, nylon, polyvinyl chloride, polyethylene, polystyrene, polyester and other plastics. Increase tensile strength, shear strength, bending strength, pressure strength, and reduce deformation.

Rubber field

Used as anti-sticking agent for rubber packing and rubber products. Increase the stability of the product shape, increase the tensile strength, shear strength, bending strength, and pressure strength.

Cable field

Used in cable rubber extender and cable isolating agent.

Ceramics field

Used in the manufacture of electric porcelain, radio porcelain, various industrial ceramics, architectural ceramics, daily-use ceramics and enamels, etc. It has the characteristics of no discoloration at high temperature, increased whiteness after calcination, uniform density, good gloss and smooth surface.

Waterproof material field

Used for waterproofing membrane, waterproof coating, waterproof ointment, etc.

Talc powder production process

Talc raw material composition analysis table

| SiO2 | MgO | 4SiO2.H2O |

| 63.36% | 31.89% | 4.75% |

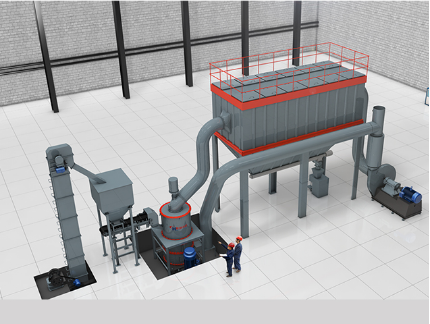

Selection scheme for main engine of talc powder making

|

Product specification (Mesh) |

400 mesh D99 |

325 mesh D99 |

600 mesh,1250 mesh,800 mesh D90 | 1250-2500 mesh |

| Selection scheme | Raymond mill or Superfine ring roller mill | |||

Remarks: 1. Select the host according to the output and fineness requirements.

1. Crush raw materials

The bulk material of talc is crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of talc are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collect finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

|

||||

| HC super large pendulum mill | HLMX ultrafine vertical mill | HCH Ring Roll Superfine Mill | ||

|

Pendulum Raymond mill has low investment cost, high output, low energy consumption, stable equipment, and low noise; it is a high-efficiency and energy-saving talc mill for fine powder below 600 mesh. |

Large-scale equipment and high output can meet the large-scale production of 3μm~45μm ultra-fine talcum powder. The vertical mill has high stability. Disadvantages: high equipment investment costs. |

Low investment cost, energy saving and environmental protection, it is an ideal milling equipment for 600-2500 mesh talc superfine powder. |

Classic Cases of Talc Milling

Equipment model and number: 2 HC1000

Processing material: Talc

Finished product fineness: 325 mesh D99

Equipment output: 4.5-5t/h

A large talc company in Guilin is one of the largest talc companies in China. The preparation of pharmaceutical-grade talc has extremely high requirements for Raymond machine equipment. For this reason, Guilin Hongcheng’s solution engineer communicated with the customer’s technical staff for many times and designed Two HC1000 Raymond machine production lines. Guilin Hongcheng Raymond machine equipment is of high quality, and the after-sales service is thoughtful. At the request of the owner, the Raymond machine has been modified many times and has achieved remarkable results. Guilin Hongcheng Company has been highly recognized by the customer.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07