- all

- product

- blog

- all

- product

- blog

marble

- 2021-04-21 15:36

- HCM

What is marble

Marble, also known as marble, is a metamorphic rock formed by the original rocks in the crust under the action of high temperature and high pressure in the crust. The main component of marble is calcium carbonate, which accounts for more than 50%. It is mainly composed of calcite, limestone, serpentine and dolomite. Stone composition. The Mohs hardness of marble is between 2.5-5, and there are many colors, usually with obvious patterns, generally containing impurities, and a lot of mineral particles. Compared with granite, marble has relatively soft physical properties, strong compressive strength and good physical and chemical properties. With the development of economy, marble plays a very important role in people's production activities.

Uses of marble

Marble has a soft, beautiful, solemn and elegant style. It is mainly used for processing into various shapes and plates, as the walls, floors, platforms and columns of buildings. It is also commonly used for monumental buildings such as monuments, towers, statues, etc. The material is an ideal material for decorating luxurious buildings; it can also be carved into practical artworks such as arts and crafts, stationery, lamps, utensils, etc. It is a traditional material for artistic carving. In addition, the crushed stones and scraps produced during the mining and processing of marble are also commonly used in the production of artificial stone, terrazzo, stone rice, and stone powder, and can be used as fillers in coatings, plastics, rubber and other industries.

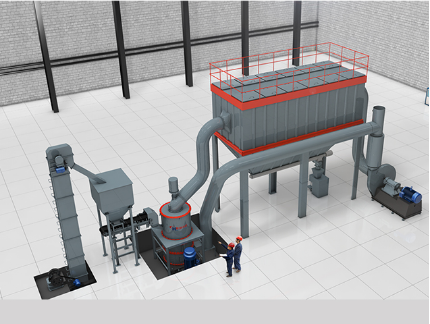

Marble milling process

Marble raw material composition analysis

| CaCO3 | MeCO3,CaO,MnO,SiO2… |

| 50% | 50% |

Marble pulverizing host selection scheme

Product specifications (mesh) |

Superfine powder processing (20-400 mesh) |

Deep processing of ultrafine powder (600-2000 mesh) |

Equipment selection scheme |

Vertical mill |

Ultrafine ring roller mill |

| Pendulum mill | Superfine vertical mill |

Remarks: Select the host according to the output and fineness requirements.

1. Crush materials

Large pieces of marble are crushed by the crusher to the fineness (15mm-50mm) that can enter the mill.

2. Milling

The crushed small pieces of limestone are sent to the storage hopper by the elevator, and then sent to the grinding chamber of the mill evenly and quantitatively by the feeder for grinding.

3. Classification

The ground material is classified by the classification system, and the unqualified powder is classified by the classifier and returned to the main engine for re-grinding.

4. Collect finished products

The powder that meets the fineness is separated and collected in the dust collector through the pipeline through the airflow. The collected finished powder is sent to the finished product silo by the conveying device through the discharge port, and then is packaged by a powder tanker or an automatic baler.

Analysis of various mills

| R-type Raymond Mill | HCH Ring Roll Superfine Mill | |

|

Low investment cost, high output, low energy consumption, stable equipment, low noise; it is an ideal equipment for processing marble fine powder. However, the large-scale equipment is lower than that of vertical mills. |

Suitable for the processing of 600-2500 mesh ultrafine powder. Low investment cost and low energy consumption. |

|

| HLM series vertical mill | HLMX superfine vertical mill | |

|

Large-scale equipment and high output can meet large-scale production. Finished product has a high degree of spheroidization and better quality, but the investment cost is higher. |

For the large-scale production of superfine powders above 600 mesh, or customers have higher requirements for the particle shape of the powder, the HLMX superfine vertical mill is the best choice. |

Classic case of marble milling

Processing material: Marble

Fineness: 800 mesh D97

Output: 6-8t/h

Equipment configuration: 2 HCH1395

Facts have proved that the Hongcheng marble mill is highly productive and efficient, and the milling technology is advanced. It is a very correct choice to choose Hongcheng. This mill is not only stable in performance and stable in operation, but also has high efficiency, reliable safety performance, environmental protection and energy saving, and excellent quality of finished products. Since the Hongcheng marble mill was officially put into this processing line, our milling efficiency has been greatly improved. With the improvement, the product market has good feedback, and the credibility has been greatly improved. We are very satisfied with this reliable product quality and caring and thoughtful service.

About us

HCM Grinding Mill,Raymond Grinding Mill, Vertical Grinding Mill, Ultrafine Grinding Mill.

Grinding Machine

latest Post

-

Application prospect of vertical pulverizer for solid waste treatment under the green development

2023-02-04 17:26

-

Superfine water slag powder instead of cement to make high value-added building materials

2023-02-04 16:48

-

The white paper on the development of China's anode material industry (2023) has been released

2023-02-03 17:13

-

Guilin Hongcheng works with you to protect the green future

2022-05-13 15:43

-

HLMX1700 Superfine Roller mill case-High-end calcium carbonate powder project with an annual output

2022-04-01 13:52

-

Comparison of advantages and disadvantages of ball mill and vertical mill

2022-01-20 15:33

-

The optimal reuse of construction waste resources has become a hot project

2022-01-20 13:47

-

Super large Raymond mill

2021-12-23 14:27

-

Guilin Hongcheng invites you to follow Bauma China 2020

2020-11-02 16:09

-

Let’s to learn about the grinding mill manufacturer - Guilin Hongcheng

2020-09-07 15:07